Self-locking sliding rail

A self-locking slide rail and self-locking technology, applied in furniture parts, home appliances, drawers, etc., can solve the problems of the inner slide rail and the middle slide rail sliding out by themselves, and the slide rail cannot be locked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

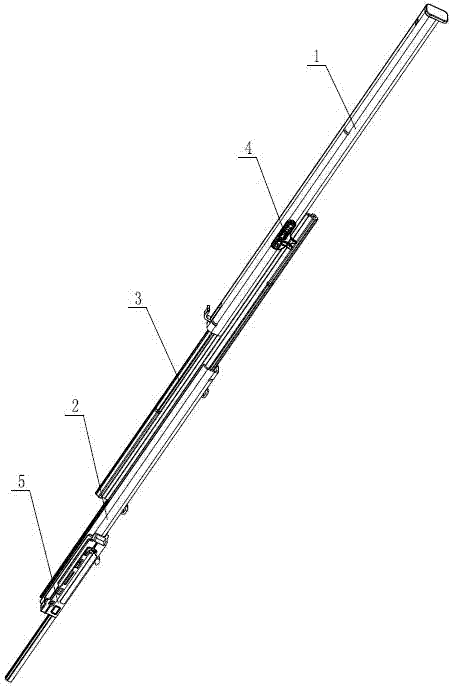

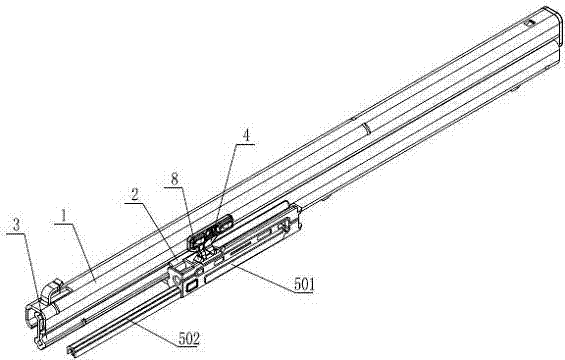

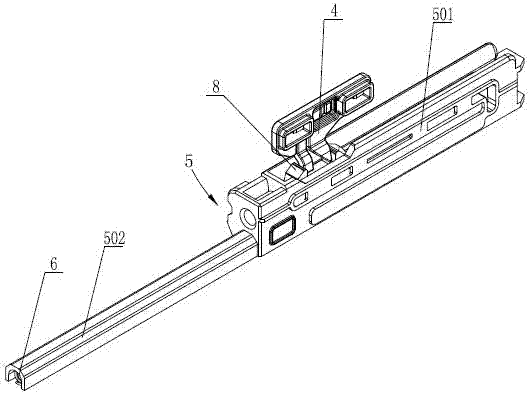

[0022] See figure 1 , figure 2 , the self-locking slide rail of the present invention comprises an inner slide rail 1, an outer slide rail 2 and a middle slide rail 3, the middle slide rail 3 is slidably arranged on the outer slide rail 2, and the inner slide rail 1 is slidably It is arranged on the middle slide rail 3; the inner slide rail 1 is fixedly connected with a dial block 4, and the outer slide rail 2 is fixedly equipped with a self-locking mechanism, and the self-locking mechanism includes a self-locking seat 5 fixedly connected to the outer slide rail 2 ,See image 3 , Figure 4 , Figure 5 , the self-locking seat 5 includes a self-locking arm 501, the bottom of the self-locking arm 501 is provided with a spring chute 5011, and the spring chute 5011 extends toward the outside of the self-locking arm 501 along the push-back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com