Pressure cooling process of segmented reinforcing type parts of hot forming steel pipe, and pressing machine hydraulic ejector rod devices

A technology of hydraulic ejector and segmental strengthening, which is applied in the field of high-strength steel stamping, can solve problems such as complex structures, and achieve the effects of unified processing technology, cost saving, and improved product strength or elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

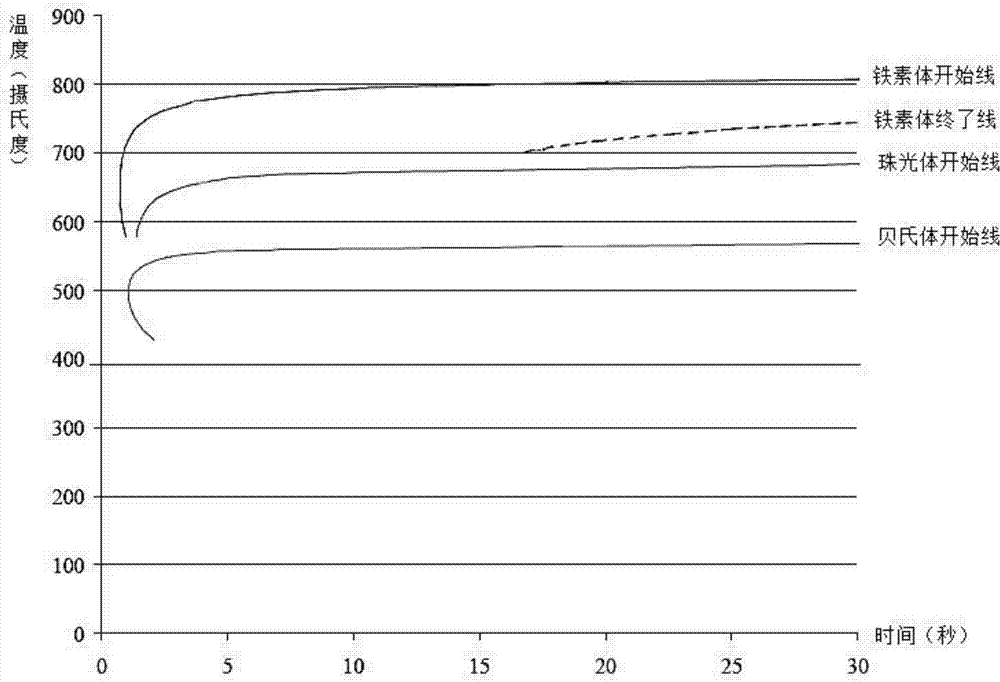

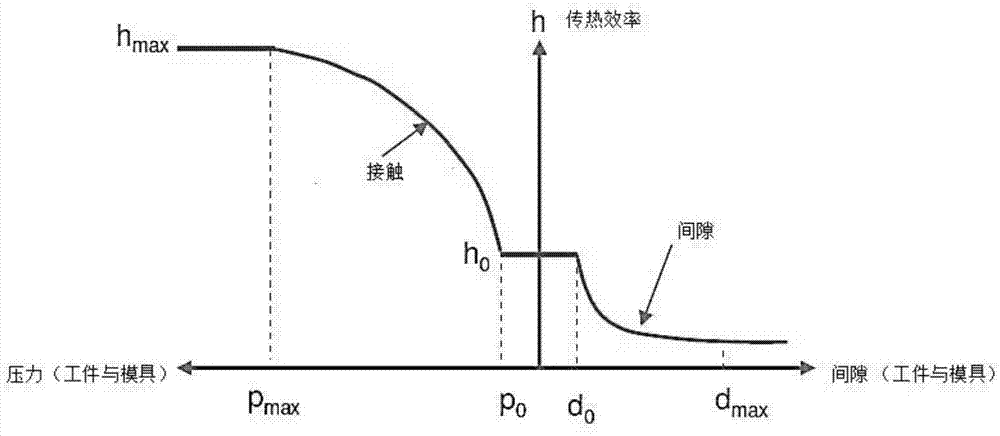

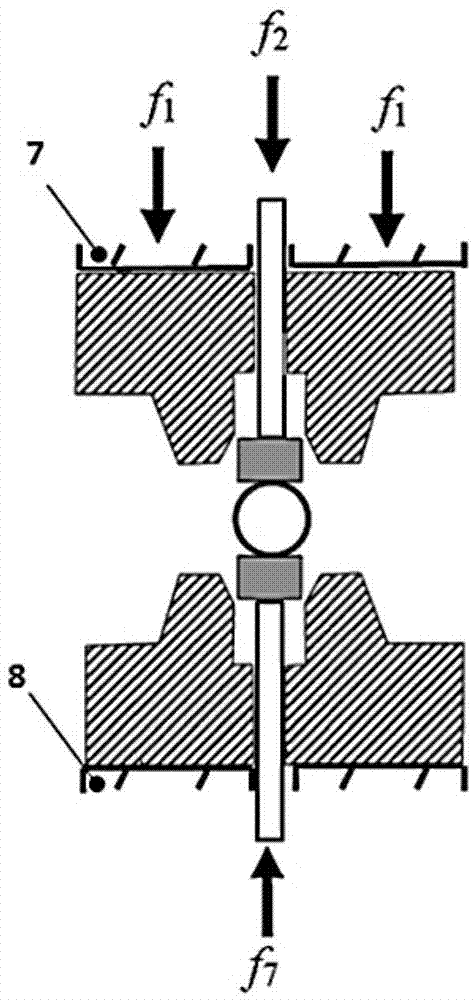

[0063] Such as Figure 3-Figure 5 As shown, the workpiece is 2.0mm thick, 150mm wide, and 1000mm long. The workpiece product requirement is f 6 The corresponding product area is HS400 soft area, and the rest are hard area HS1150. The concrete preparation process schematic diagram of this method, wherein:

[0064] figure 1 In its original state, according to figure 1 It can be seen that the device for realizing this method includes: an upper die 1, a lower die 2, a hydraulic ejector pin 3 for the upper slider of the press, a hydraulic ejector pin 4 for the lower workbench of the press, an upper die pressing core 5, a lower die pressing core 6, a press The upper slide block 7, the lower workbench 8 of the press, and the mold mandrel 9.

[0065] The upper mold 1 covers the range of HS1150 in the hard area of the product, and the material is high-quality mold steel SKD61;

[0066] The upper mold pressing material core 5 covers the product soft zone HS400 range, and the mat...

Embodiment 2

[0078] Such as Figure 3-Figure 5 As shown, the workpiece is 2.0mm thick, 150mm wide, and 1000mm long. The workpiece product requirement is f 6 The corresponding product area is HS400 soft area, f 8 The area is the soft area HS700, and the rest of the product area is the hard area HS1150.

[0079] This method realizes the device such as figure 1 shown, where:

[0080] The upper mold 1 covers all areas of the product soft area HS700 and hard area HS1150, and the material is high-quality die steel SKD61;

[0081] The upper mold pressing material core 3 covers all areas of the soft area HS700 of the product, and the material is high-quality mold steel SKD61;

[0082] The lower mold pressing material core 6 covers all areas of the soft area HS700 of the product, and the material is high-quality mold steel SKD61;

[0083] The lower mold 2 covers all areas of the hard area HS1150 of the product, and the material is high-quality mold steel SKD61;

[0084] The upper and lower h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com