Layering, aligning and mounting system for drying pallets for egg trays made of paper pulp

An installation system and tray technology, which is applied in the field of layered alignment installation system for pulp egg tray drying trays, can solve the problems of inconvenient use and operation, large manpower and material resources, and low production efficiency, and achieve simple operation, low input cost, and high installation efficiency. The effect of high car efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

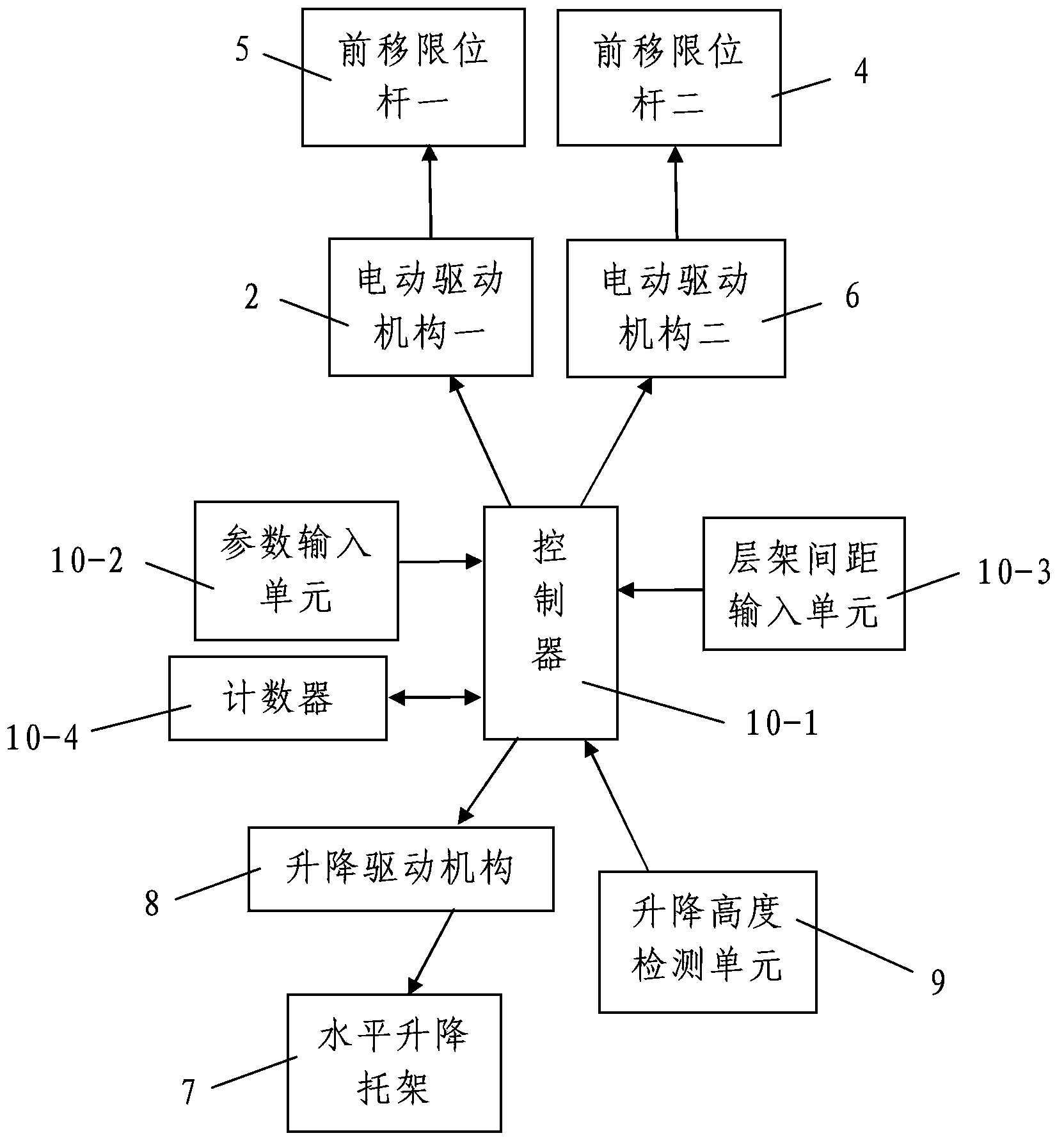

[0020] Such as figure 1 As shown, the present invention includes a drying tray alignment installation vehicle that can move back and forth between the egg tray forming machine and the drying tray transport vehicle, and is arranged on the front side of the egg tray forming machine for the drying tray to transport The first moving track that the vehicle moves back and forth and the second moving track that is arranged between the first moving track and the egg tray forming machine and used for the alignment installation vehicle of the drying tray to move back and forth, the first moving track and the second moving track The second moving track is arranged vertically, and a layered alignment control box is arranged on one side of the egg tray forming machine. The moving track 1 is provided with a transport vehicle forward movement limiting mechanism that limits the forward position of the drying tray transport vehicle, and the transport vehicle forward movement limiting mechanism...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap