Front water purifier and scale inhibitor

A pre-water purification and anti-scaling technology, applied in descaling and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

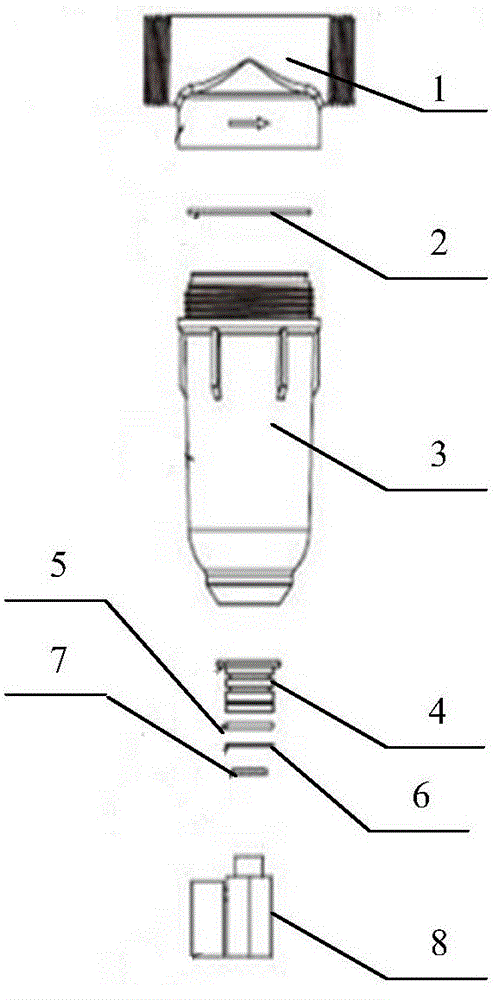

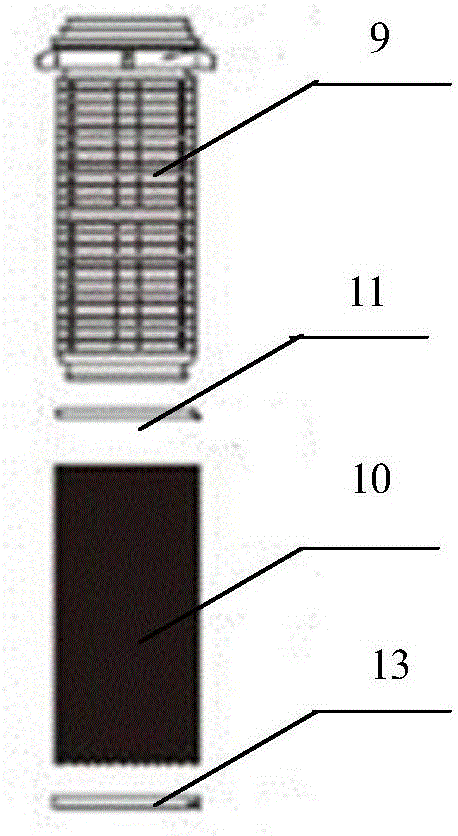

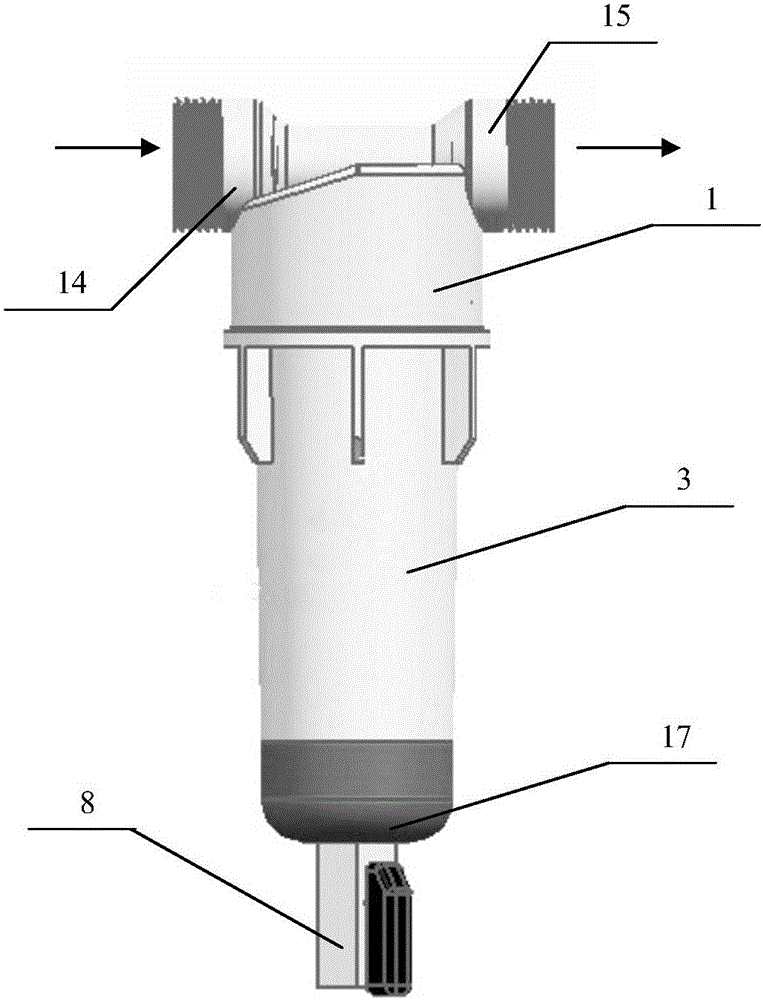

[0029] Embodiment one, such as Figure 5 , 6 Shown, anti-scaling body comprises anti-scaling sheet 18, and described anti-scaling sheet 18 is circular cake, is provided with central hole 19 at the center of anti-scaling sheet 18, is provided with filter hole 20 around central hole 19, The axis of the central hole 19 is perpendicular to the end face of the anti-scaling sheet 18, the axis of the water filter hole 20 is at an angle of 90° to the end face of the anti-scaling sheet 18, and all the anti-scaling sheets 18 are set on the screw rod 21 through the central hole 19, adjacent to each other. The two anti-scaling sheets 18 are separated by a spacer 22, and are screwed and fixed by nuts 23. The anti-scaling sheet 18 is placed in the tube body 9, and the gap between the anti-scaling sheet 18 and the tube body 9 fits.

Embodiment 2

[0030] Embodiment two, the difference between this embodiment and embodiment one is that the anti-scaling body is a granular filter material, and the inner wall of the opening end of the anti-scaling pipe body 9 is fixedly covered with a ring 25, and the outer diameter of the ring 25 is the same as that of the pipe. Body 9 inner diameters are the same, as Figure 7 , 8 As shown, the end of the ring 25 facing the open end of the pipe body 9 is provided with a ring groove, and a filter screen 24 is placed on the ring groove, and a snap ring 26 is provided on the filter screen 24, and the snap ring 26 is closely matched with the ring 25, and the filter screen 24 is fixed on the ring 25. The filter screen 24 and the pipe body 9 form a chamber, and the filter material is placed in the chamber, and the filter material is evenly distributed in the pipe body 9, so that the maximum area can be in contact with water, so as to better prevent scale and scale. The mesh number of the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com