Method for smelting low-phosphorus steel by using semi-steel

A low-phosphorus steel and steel smelting technology, which is applied in the manufacture of converters, etc., can solve the problems that it is difficult to meet the needs of low-phosphorus high-grade steel types, the amount of slag is difficult to control, and the phosphorus in molten steel is serious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

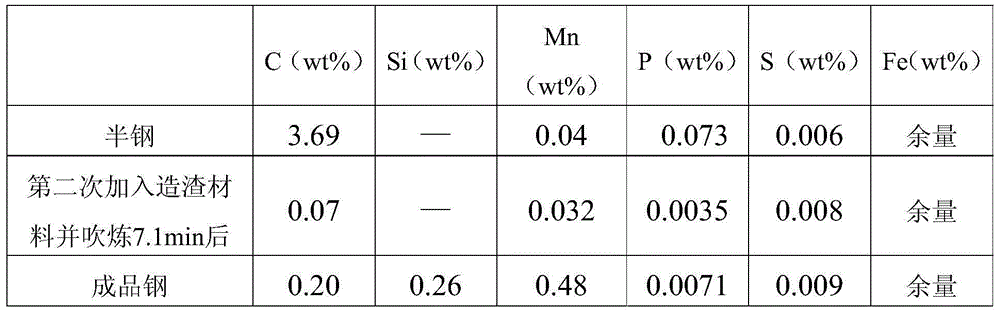

example 1

[0035] The semi-steel after desulfurization and vanadium extraction is used as the raw material, and its main components are shown in Table 1, and the 120t combined blowing converter is used for blowing. After the semi-steel is mixed into the converter, the oxygen lance starts to blow oxygen, the oxygen blowing pressure is 0.89MPa, and the oxygen supply intensity is 3.81m 3 / min·t 钢 . While starting to blow oxygen, add 28.4kg / t to the furnace 钢 active lime, 6.3kg / t 钢 of high magnesium lime and 31.2kg / t 钢 The composite slagging agent should be added within 3 minutes after the oxygen supply is started. At 6.1 minutes of blowing, the oxygen lance was raised to stop the oxygen supply, 60-80wt% slag by weight was poured out from the shaking furnace, and the temperature of the converter bath was 1476°C.

[0036] After slag dumping, the second blowing is carried out, the oxygen blowing pressure is 0.88MPa, and the oxygen supply intensity is 3.82m 3 / min·t 钢 , at the same time,...

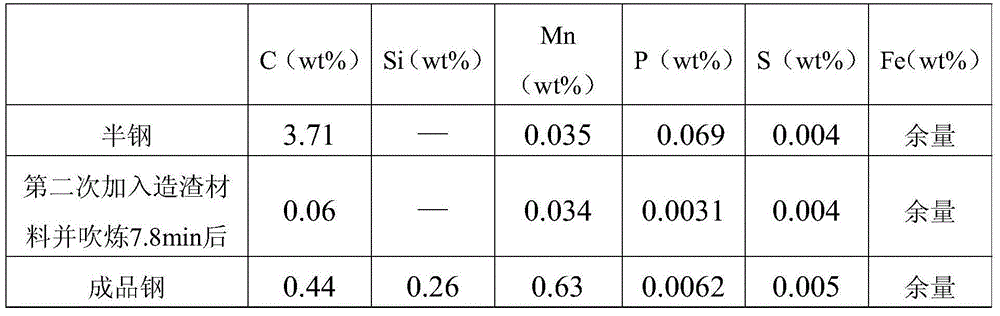

example 2

[0041] The semi-steel after desulfurization and vanadium extraction is used as the raw material, and its main components are shown in Table 2, and a 120t combined blowing converter is used for blowing. After the semi-steel is blended into the converter, the oxygen gun is lowered to start blowing oxygen, the oxygen blowing pressure is 0.88MPa, and the oxygen supply intensity is 3.83m 3 / min·t 钢 . While starting to blow oxygen, add 29.3kg / t to the furnace 钢 active lime, 7.1kg / t 钢 of high magnesium lime and 32.6kg / t 钢 Composite slagging agent, and all added within 3 minutes of starting to blow and supply oxygen. At 6.1 minutes of blowing, the oxygen lance was raised to stop the oxygen supply, 60-80wt% slag by weight was poured out from the shaking furnace, and the temperature of the converter bath was 1482°C.

[0042] After slag dumping, the second blowing is carried out, the oxygen blowing pressure is 0.86MPa, and the oxygen supply intensity is 3.83m 3 / min·t 钢 , at the s...

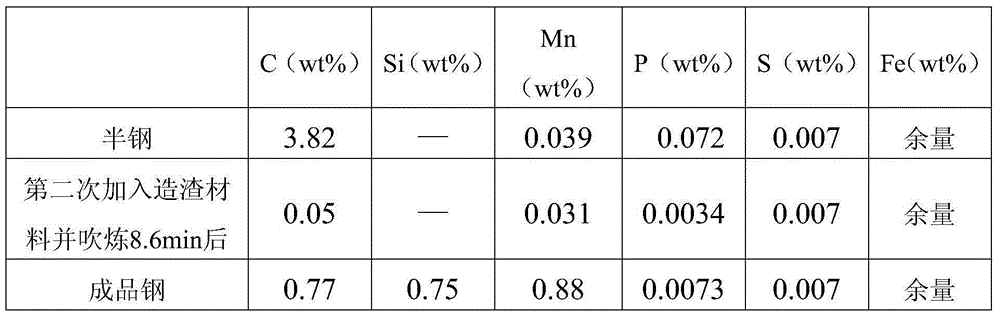

example 3

[0047] The semi-steel after desulfurization and vanadium extraction is used as the raw material, and its main components are shown in Table 3, and the 120t combined blowing converter is used for blowing. After the semi-steel is blended into the converter, the oxygen gun is lowered to start blowing oxygen, the oxygen blowing pressure is 0.86MPa, and the oxygen supply intensity is 3.61m 3 / min·t 钢 . While starting to blow oxygen, add 28.9kg / t to the furnace 钢 active lime, 6.8kg / t 钢 of high magnesium lime and 31.9kg / t 钢 Composite slagging agent, and all added within 3 minutes of starting to blow and supply oxygen. At 6.4 minutes of blowing, the oxygen lance was raised to stop the oxygen supply, 60-80wt% slag by weight was poured out from the shaking furnace, and the temperature of the converter bath was 1517°C.

[0048] After slag dumping, the second blowing is carried out, the oxygen blowing pressure is 0.88MPa, and the oxygen supply intensity is 3.65m 3 / min·t 钢, at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com