Patents

Literature

32results about How to "Increase distribution concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

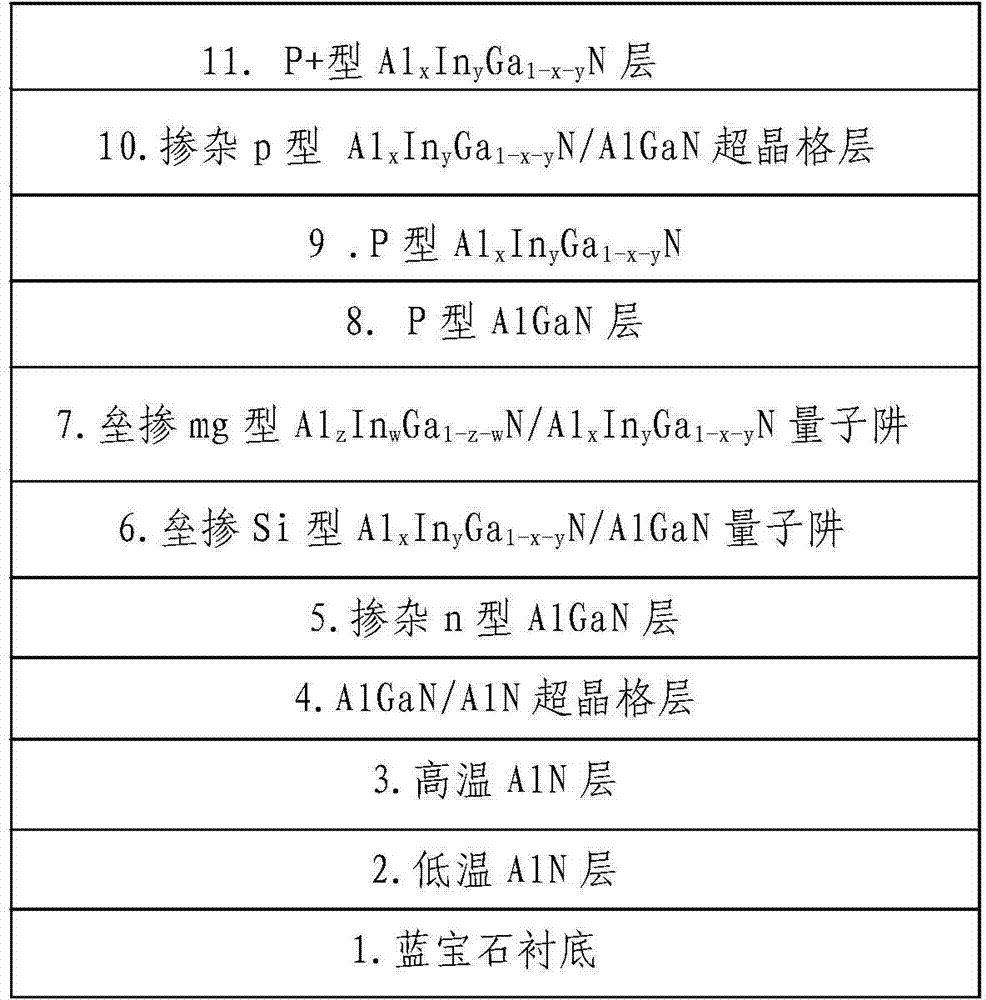

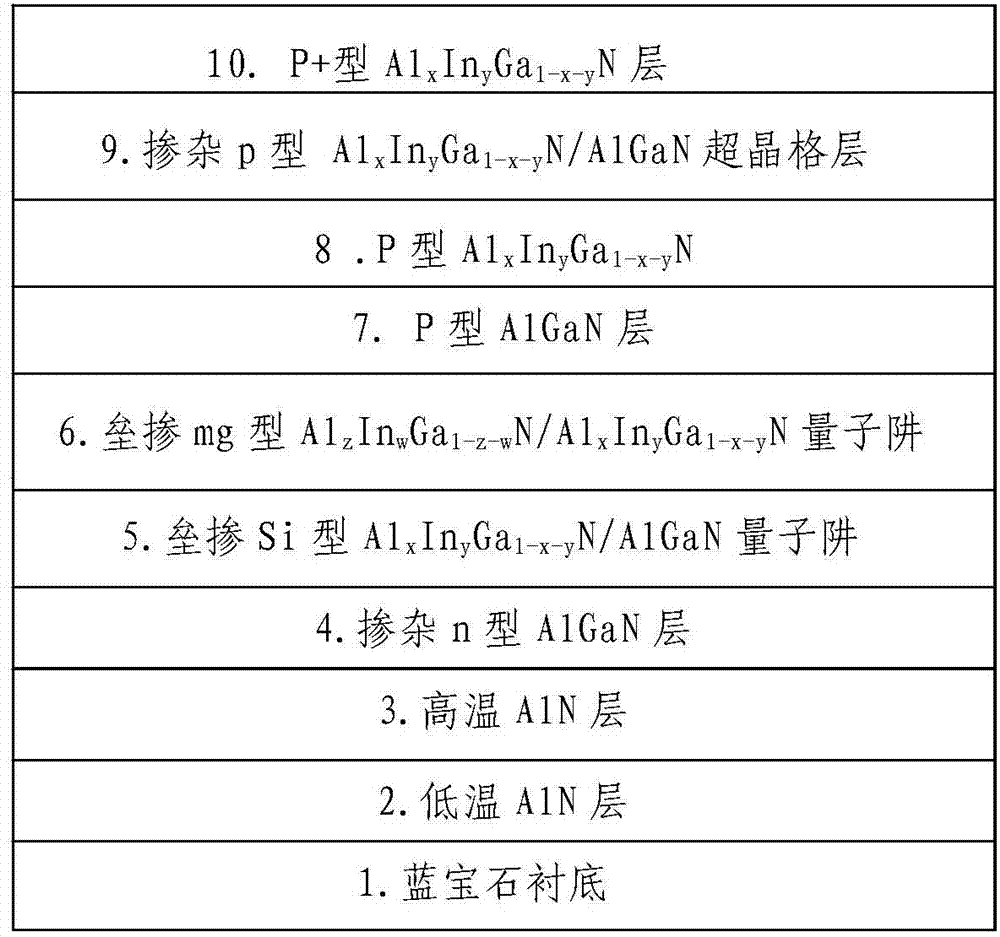

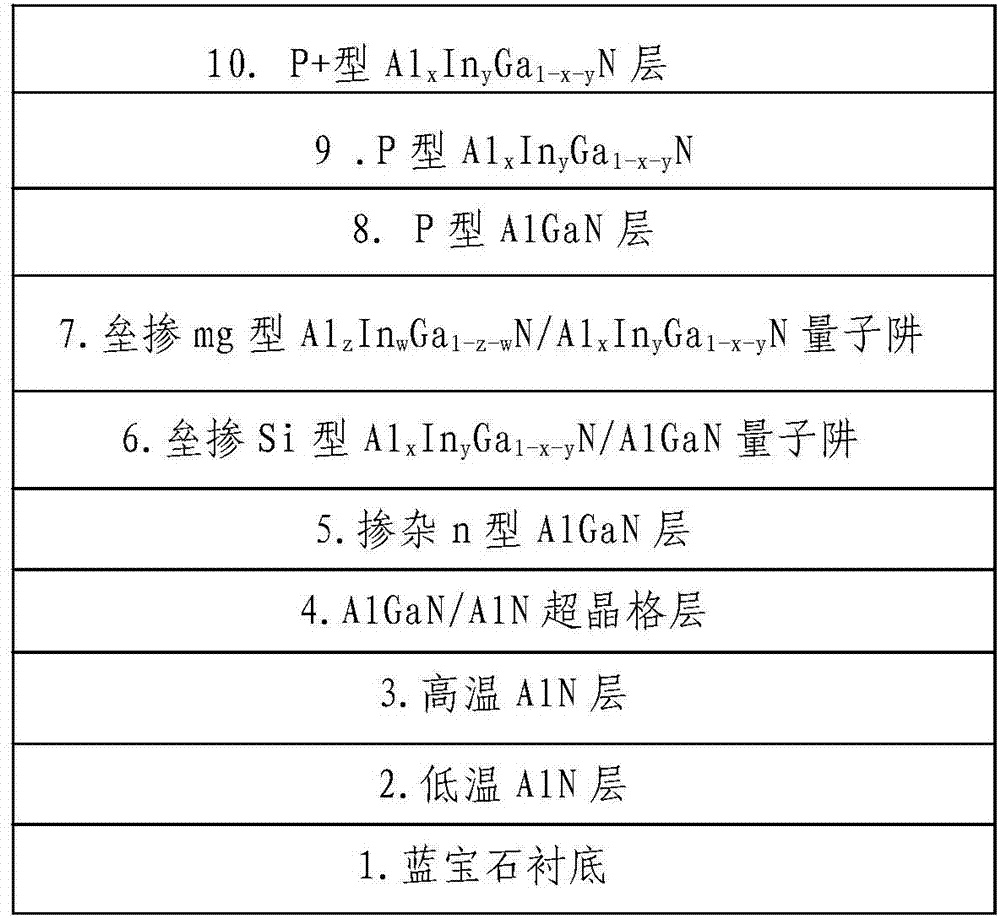

Method for epitaxial growth of ultraviolet LED with high luminous efficacy

The invention provides a new method for epitaxial growth of an ultraviolet LED. By the adoption of the method for epitaxial growth of the ultraviolet LED, the growth difficulty can be greatly lowered, and the radiant power of the ultraviolet LED is greatly increased. An AlGaN / AlxInyGa1-x-y layer is grown for a plurality of periods, wherein x, y, z and w meet the following requirements for x

Owner:西安利科光电科技有限公司

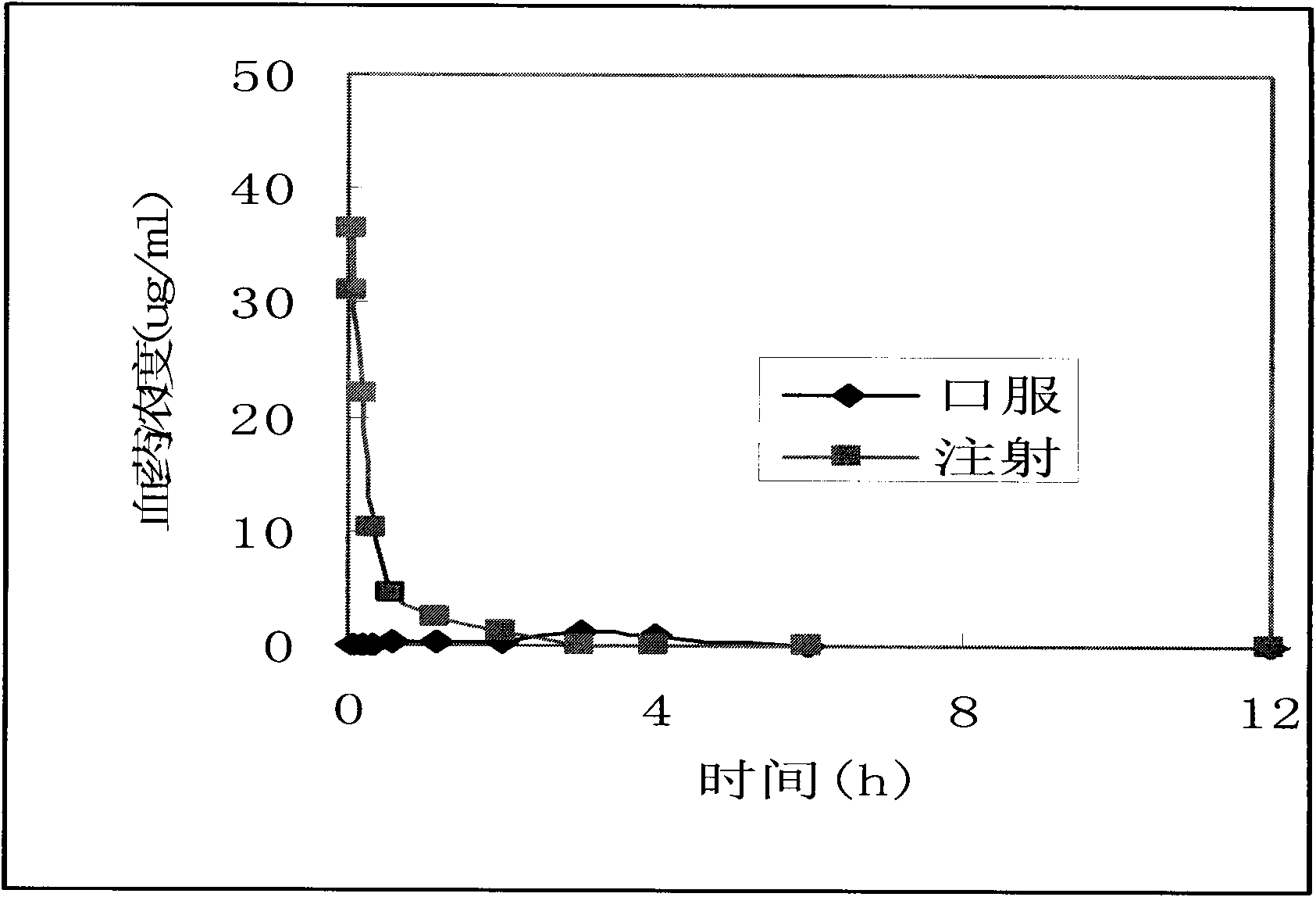

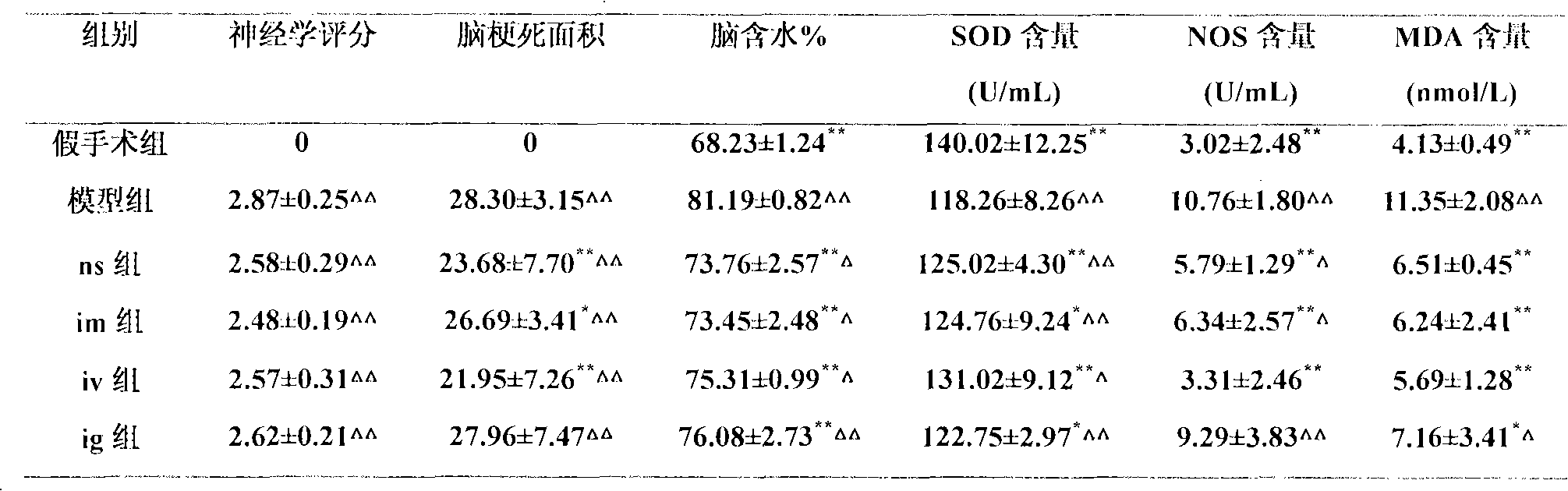

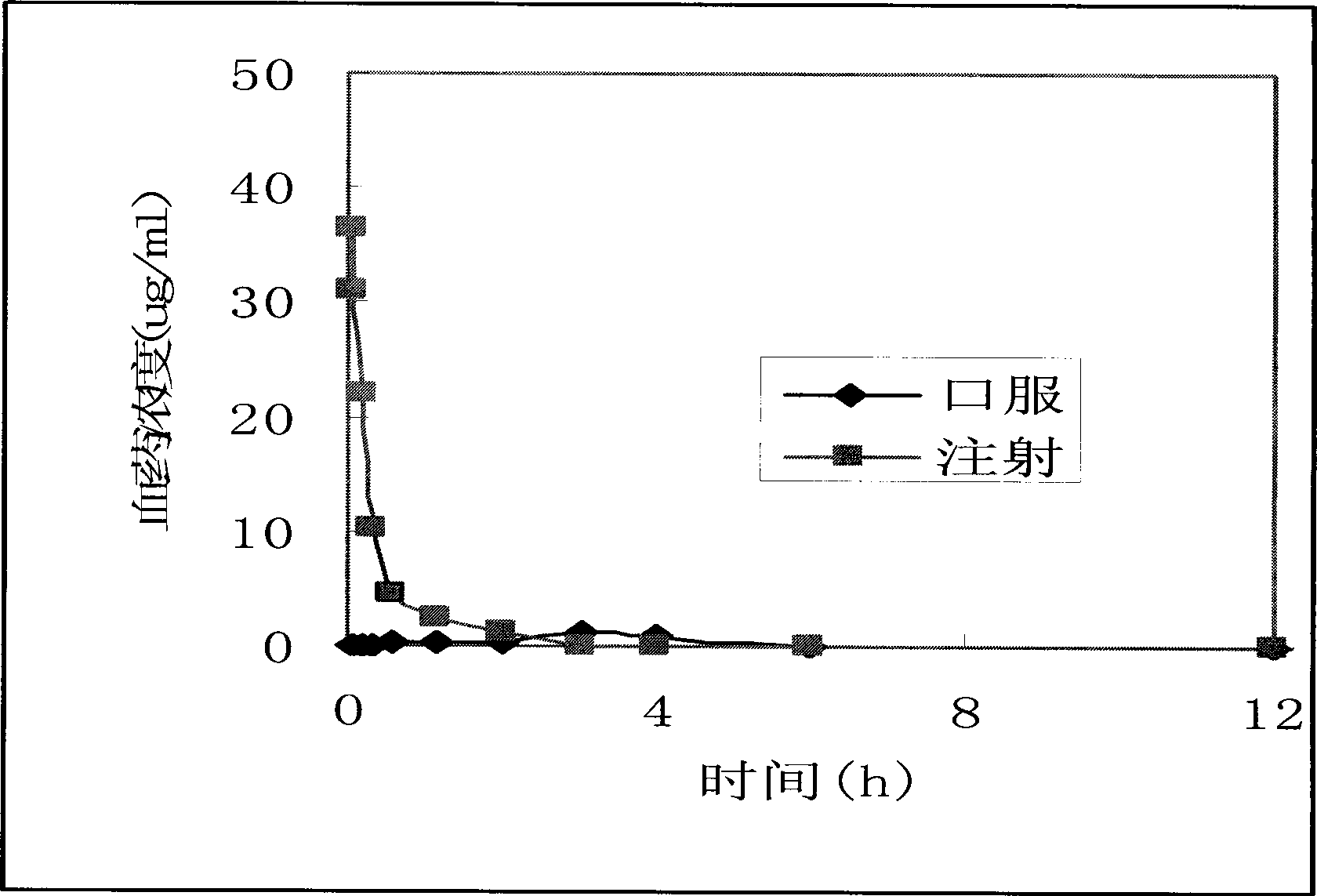

Bicyclo-ethanol submicron emulsion and preparation method thereof

ActiveCN101524329AImprove solubilityGood chemical stabilityDigestive systemEmulsion deliveryOrganosolvOil phase

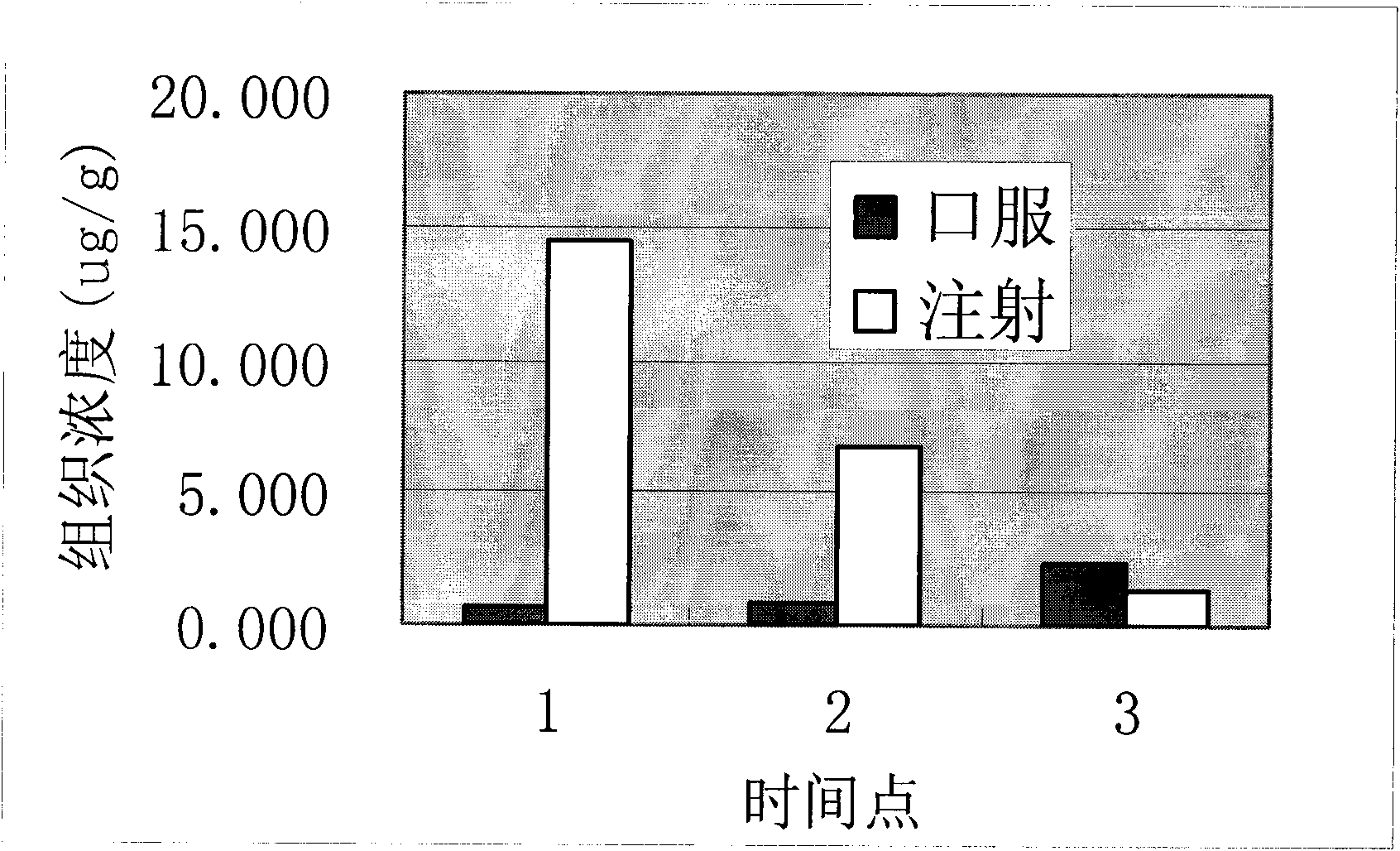

The invention discloses a bicyclo-ethanol submicron emulsion and a preparation method thereof. the preparation method comprises the steps of dissolving bicyclo-ethanol and emulsifying agent in an oil phase, adding an assistant for emulsifying agent, a stabilizing agent, other additive and a water phase, adopting a cutting dispersing and high-pressure homogeneous emulsification process to prepare an oil-in-water(O / W) submicron emulsion with the average grain diameter below 500 nm and drug loading dosage between 0.01mg / ml and 5mg / ml. The bicyclo-ethanol submicron emulsion is injected through vein and used for treating medium and serious hepatitis. The prepared submicron emulsion does not contain solubilizer such as Tween-80 or organic solvent, can be mixed with glucose injection, physiological saline or distilled water according to random proportion, and can not easily generate insoluble particulates when stored, used or matched with other components, thereby having high security and good stability. The invention also relates to various preparations of the bicyclo-ethanol submicron emulsion.

Owner:INST OF MATERIA MEDICA CHINESE ACAD OF MEDICAL SCI +1

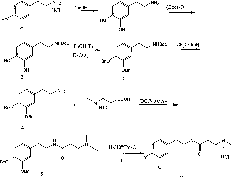

Application of organic amine derivatives as brain-targeting modification group of small-molecule drug

InactiveCN101822841AIncrease distribution concentrationImprove the effect of brain functionNervous disorderOrganic chemistryPerylene derivativesPharmaceutical Substances

The invention discloses an application of organic amine derivatives as the brain-targeting modification group of small-molecule drug and further relates to an organic amine compound having the structure thereof as shown in formula (I), and a preparation method thereof, wherein part B is particularly a central-active drug D, and part A is particularly the targeting modification group of organic amine derivatives. The organic amine compound having the structure as shown in formula (I) and targeting on the brain can significantly increase the aggregation concentration of the drug of the part B on the brain, extend the aggregation time thereof at the brain or improve the effect thereof on the brain.

Owner:SICHUAN UNIV

Converter smelting method for improving end molten steel remainder Mn with medium-high-Mn, high-P and low-Si molten iron

ActiveCN109097522AIncrease the residual Mn contentReduce back phosphorusManufacturing convertersProcess efficiency improvementSteelmakingAlkalinity

The invention discloses a converter smelting method for improving end molten steel remainder Mn with medium-high-Mn, high-P and low-Si molten iron (C4.20-4.60wt, Mn 0.90wt%-1.15wt%, Si 0.05-0.15wt%, P0.100-0.130wt% and S smaller than or equal to 0.040wt%). Integrated innovation is conducted on processes such as slag retention operation, continuous casting residual slag application, low-alkalinityslagging process, constant-pressure low lance position operation in the smelting process and tapping slag washing in the whole process, smelting reaction dynamics and thermodynamic conditions are optimized, the distribution concentration of MnO in slag in the smelting process is increased, better smelting slagging and dephosphorization effects are obtained under the conditions of little slag andlow-alkalinity slag systems, rephosphorization of molten steel in the later period of smelting and the tapping process is reduced to the greatest extent, the content (0.43wt%-0.55wt%) of end point molten steel residual Mn is significantly increased, the addition amount of Mn alloys in the deoxidation alloying process is reduced, the steelmaking alloy consumption and alloying cost are significantlyreduced, the economic indexes of the smelting technology is improved, and the market competitiveness of products is improved.

Owner:WUKUN STEEL

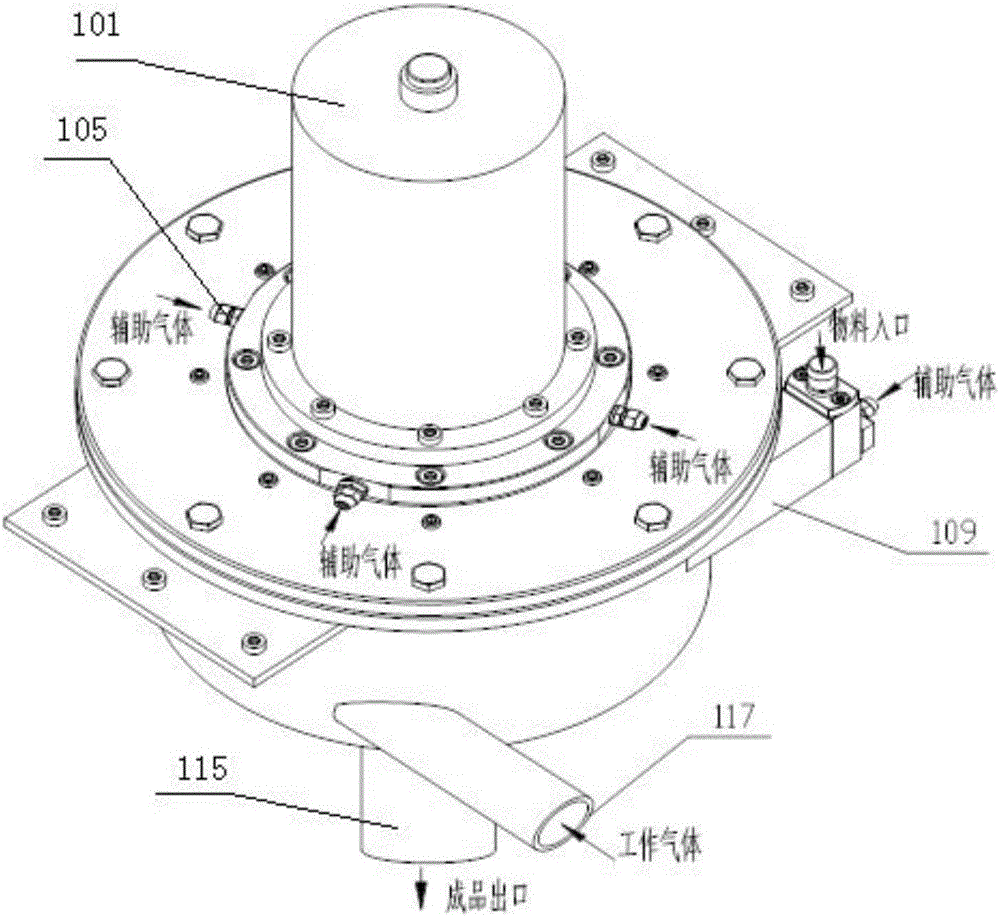

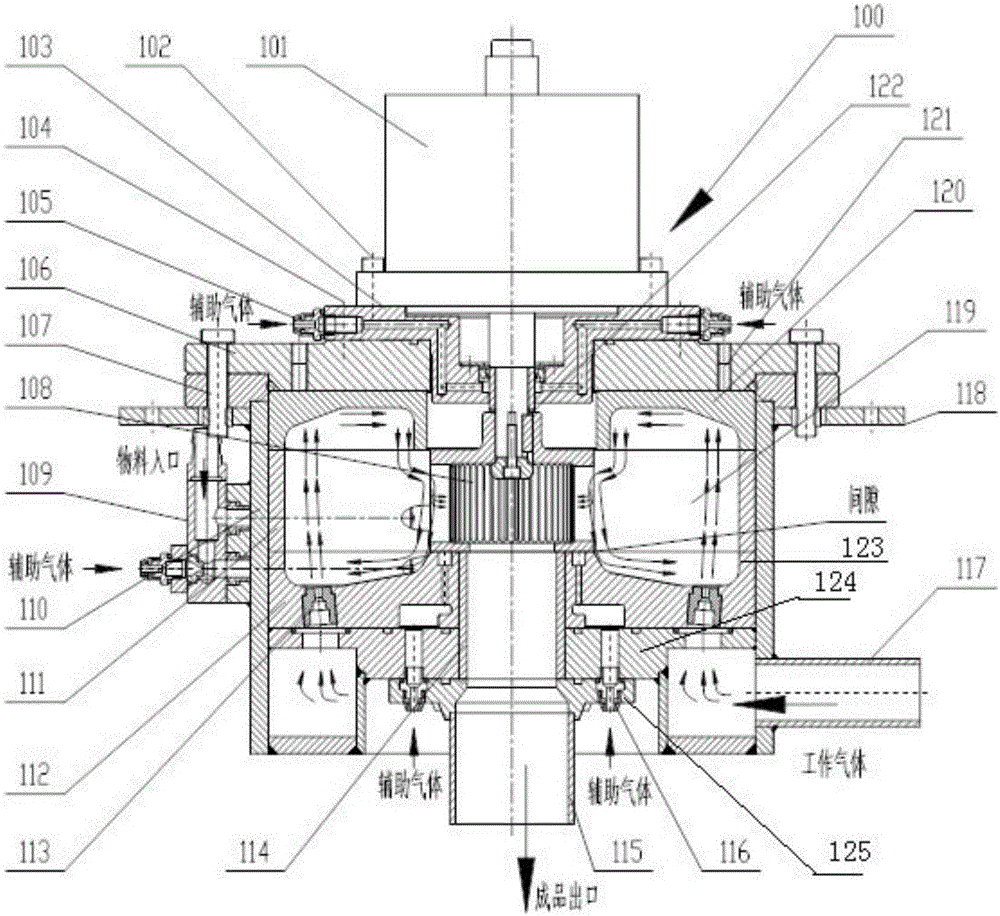

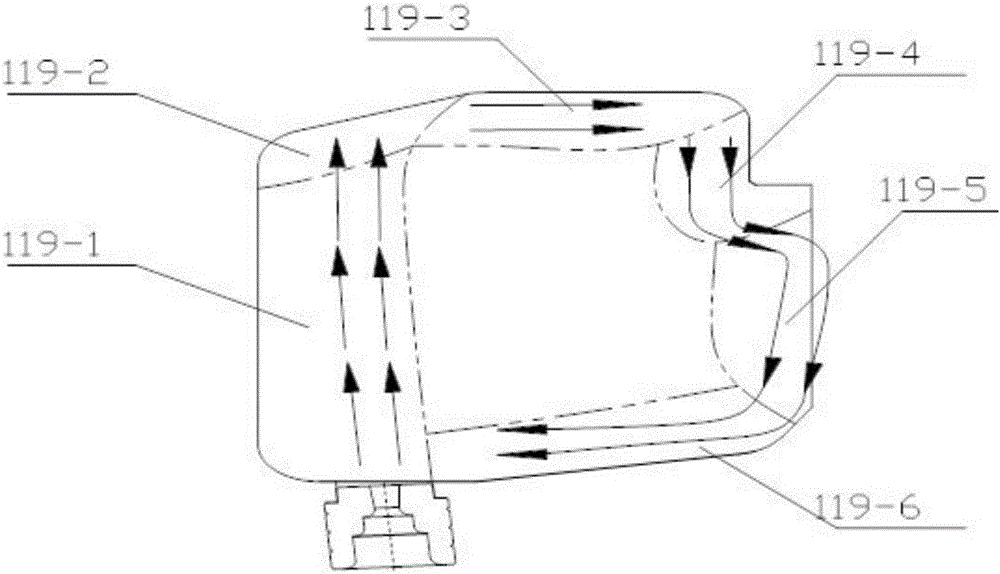

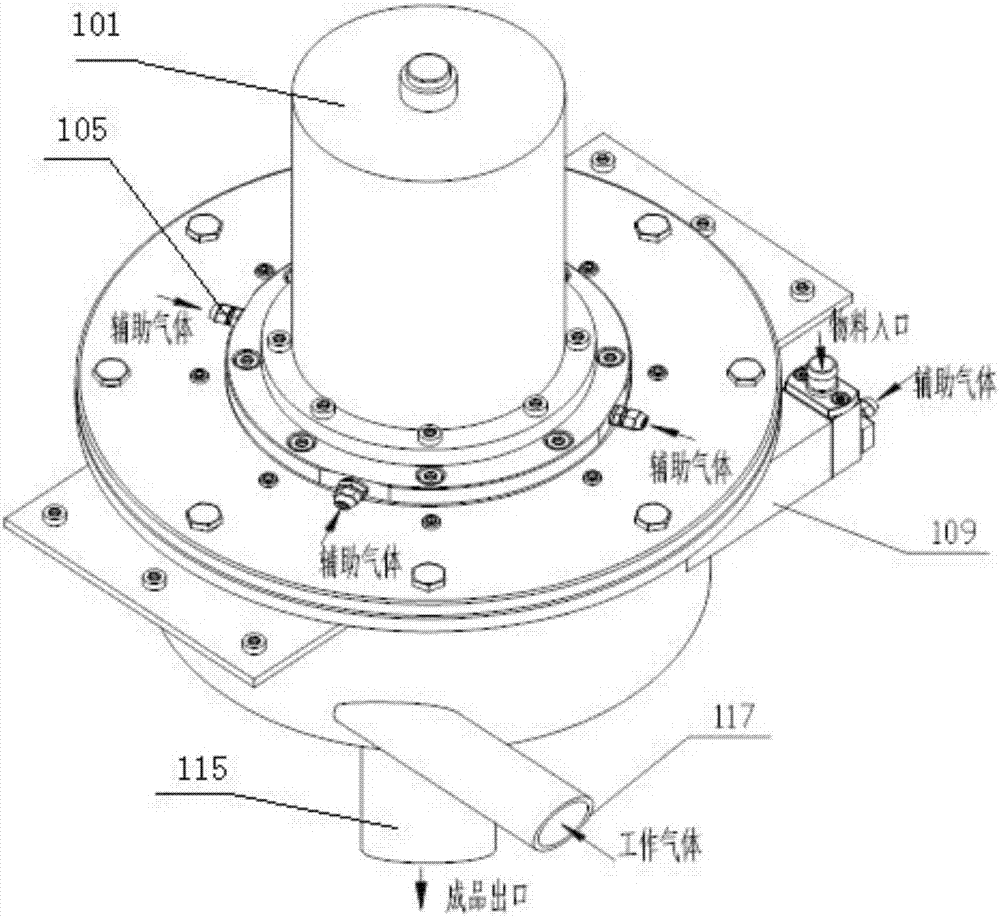

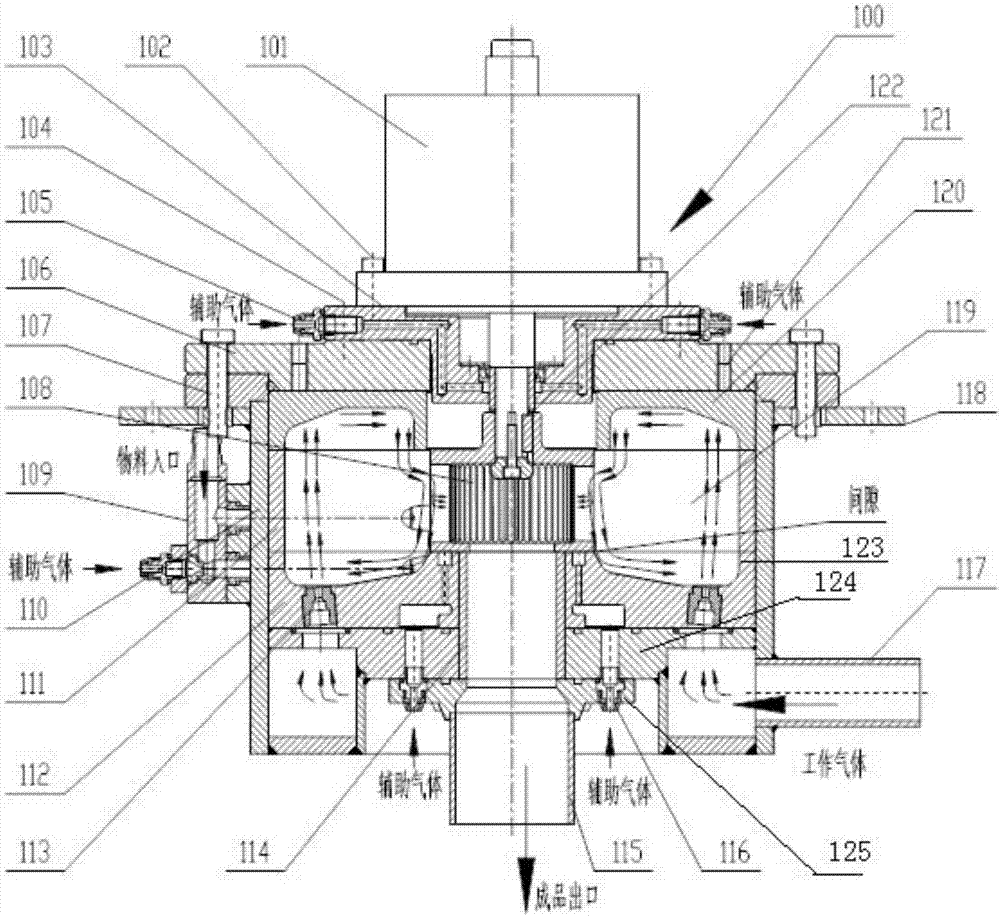

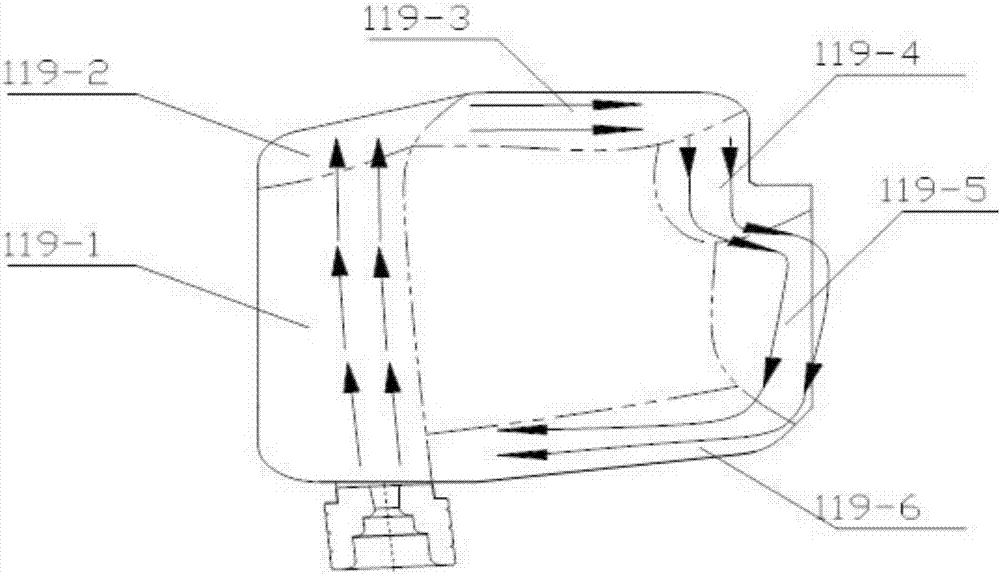

Micro-powder airflow mill

ActiveCN106179667AGuaranteed continuityGuaranteed uniformityGas current separationGrain treatmentsParticle-size distributionAirflow

The invention relates to a micro-powder airflow mill. The micro-powder airflow mill is characterized in that an adjusting gasket and a sorting wheel are arranged on a motor spindle; a motor base is fixedly connected to an upper cover; the upper cover is fixedly connected to a supporting plate of a mill chamber outer shell; the periphery of the motor base is connected with a plurality of air connectors; a mill chamber inner shell is arranged in the mill chamber outer shell; a cavity of the mill chamber inner shell serves as a mill chamber; the bottom of a nozzle fixing disc of the mill chamber inner shell is fixedly connected with a plurality of nozzles; the nozzle fixing disc of the mill chamber inner shell is arranged on a bottom disc; the lower end of the bottom disc is fixedly connected with auxiliary air connectors; the multiple auxiliary air connectors are fixedly connected to an auxiliary air connector fixing seat; a discharging bush is arranged in the center of the nozzle fixing disc and the center of the bottom disc; a clearance is arranged between the end face of the sorting wheel and the end face of the nozzle fixing disc; a feeding mechanism and an air inlet pipe are fixedly connected to the outer circumference face of the mill chamber outer shell; and the lower end of the discharging bush is connected with a finished product discharge opening. The micro-powder airflow mill is reasonable in structure, the material particle size distribution concentration ratio can be effectively increased, product quality is good, and cost is low.

Owner:吉林市新大科机电技术有限责任公司

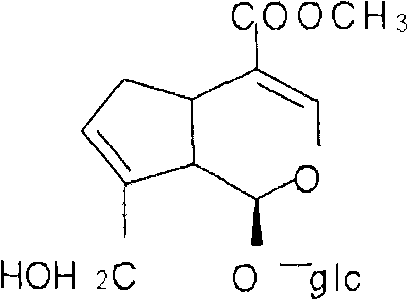

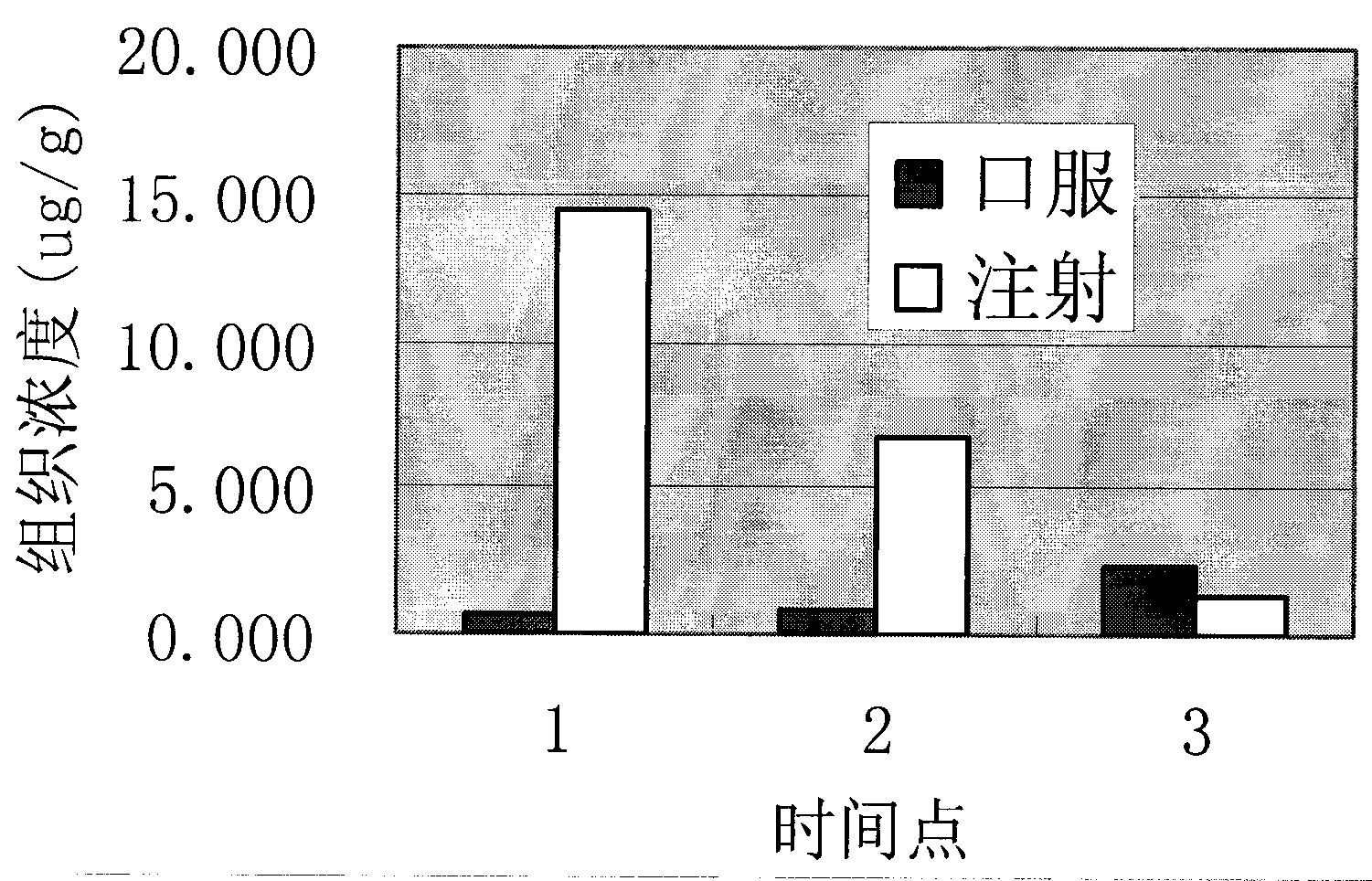

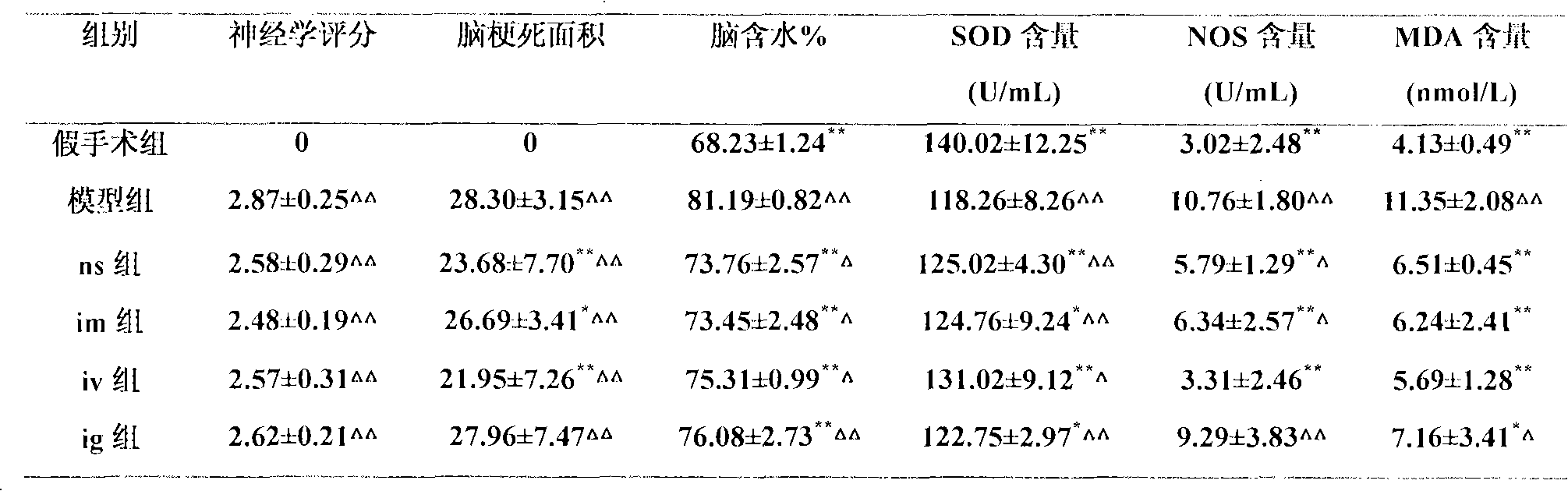

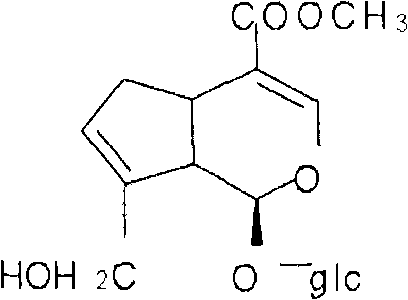

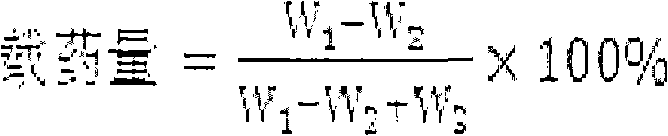

Jasminoidin or gardenia total iridoid glycoside liposome preparation

ActiveCN102309449AIncrease distribution concentrationGood treatment effectOrganic active ingredientsAerosol deliveryYolkGenipin

The invention discloses a jasminoidin or gardenia total iridoid glycoside liposome preparation which comprises liposome formed by phospholipid and cholesterol, and asminoidin or gardenia total iridoid glycoside wrapped and loaded in the liposome, wherein the weight ratio of phospholipid to cholesterol is (3:1)-(7:1), preferably 5:1; the weight ratio of asminoidin or gardenia total iridoid glycoside to phospholipid is (1:2)-(1:8), preferably 1:4; and the phospholipid is selected from lecithin, soya lecithin, yolk phospholipid or phosphatidylcholine, preferably soya lecithin or yolk phospholipid. The preparation provided by the invention has the advantages that the contact time of the asminoidin or gardenia total iridoid glycoside and mucosa is prolonged. The liposome preparation can be prepared into a spraying agent after being loaded into a nasal suction apparatus, and is applied in a nasal delivery mode, so that the distribution of the asminoidin or gardenia total iridoid glycoside in brain tissues is effectively improved. The invention also discloses the application of the liposome preparation in preparation of medicaments for treating hypoxic ischemic brain damage diseases.

Owner:JIANGXI UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

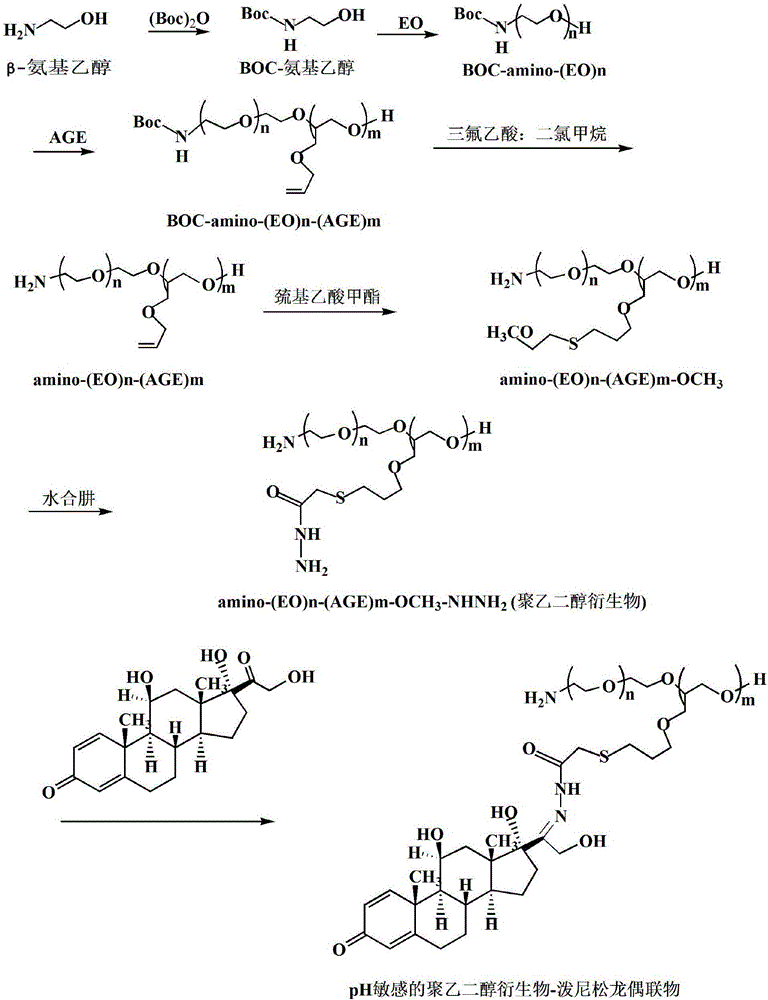

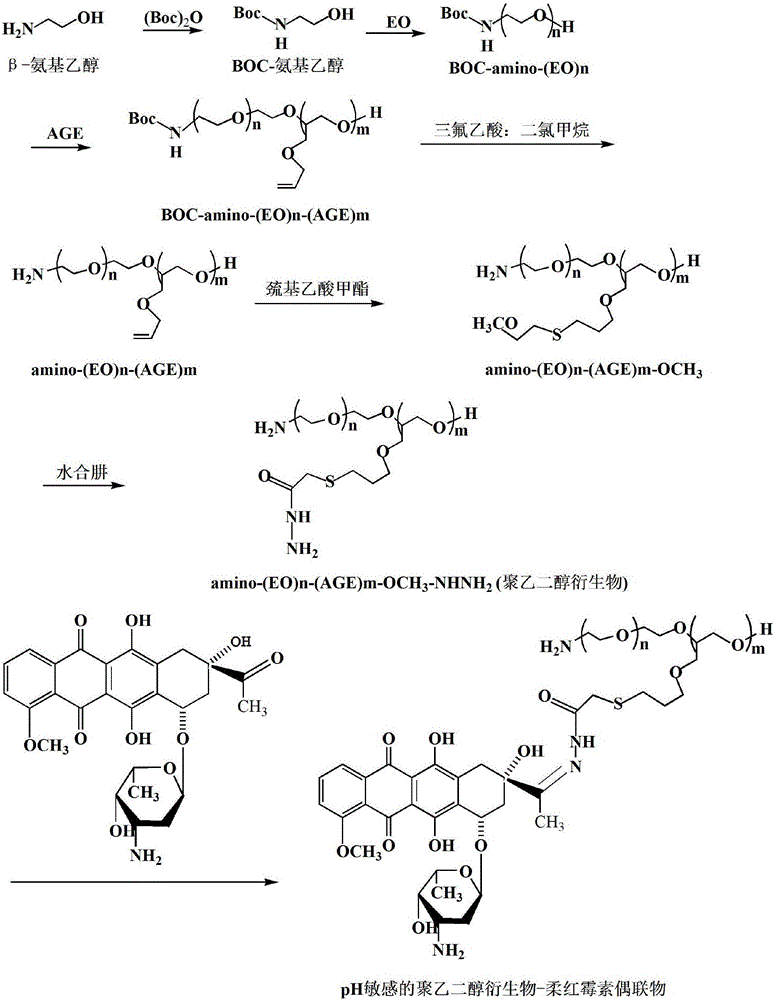

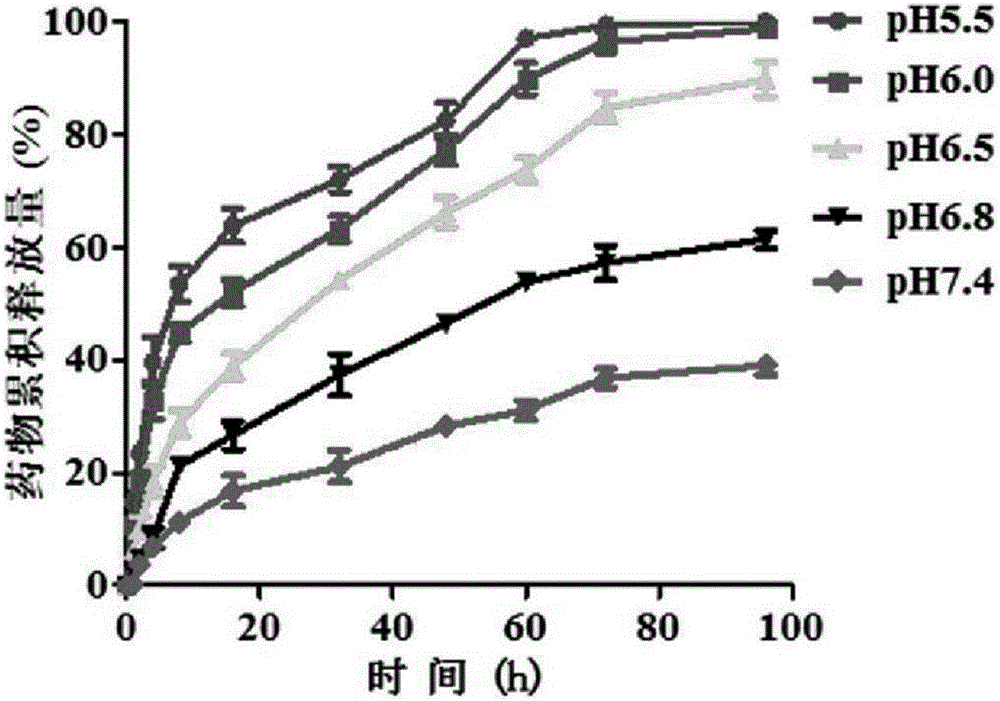

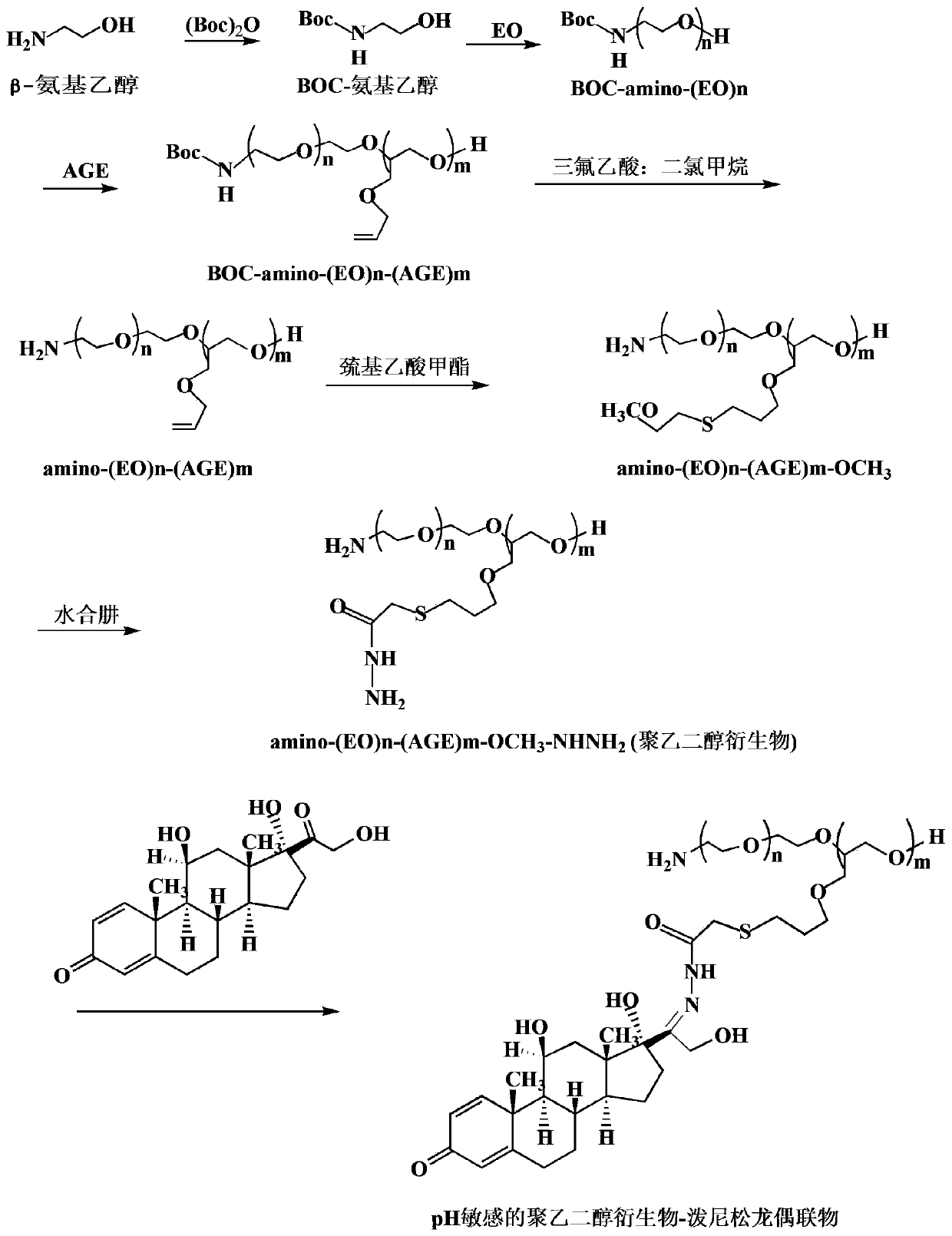

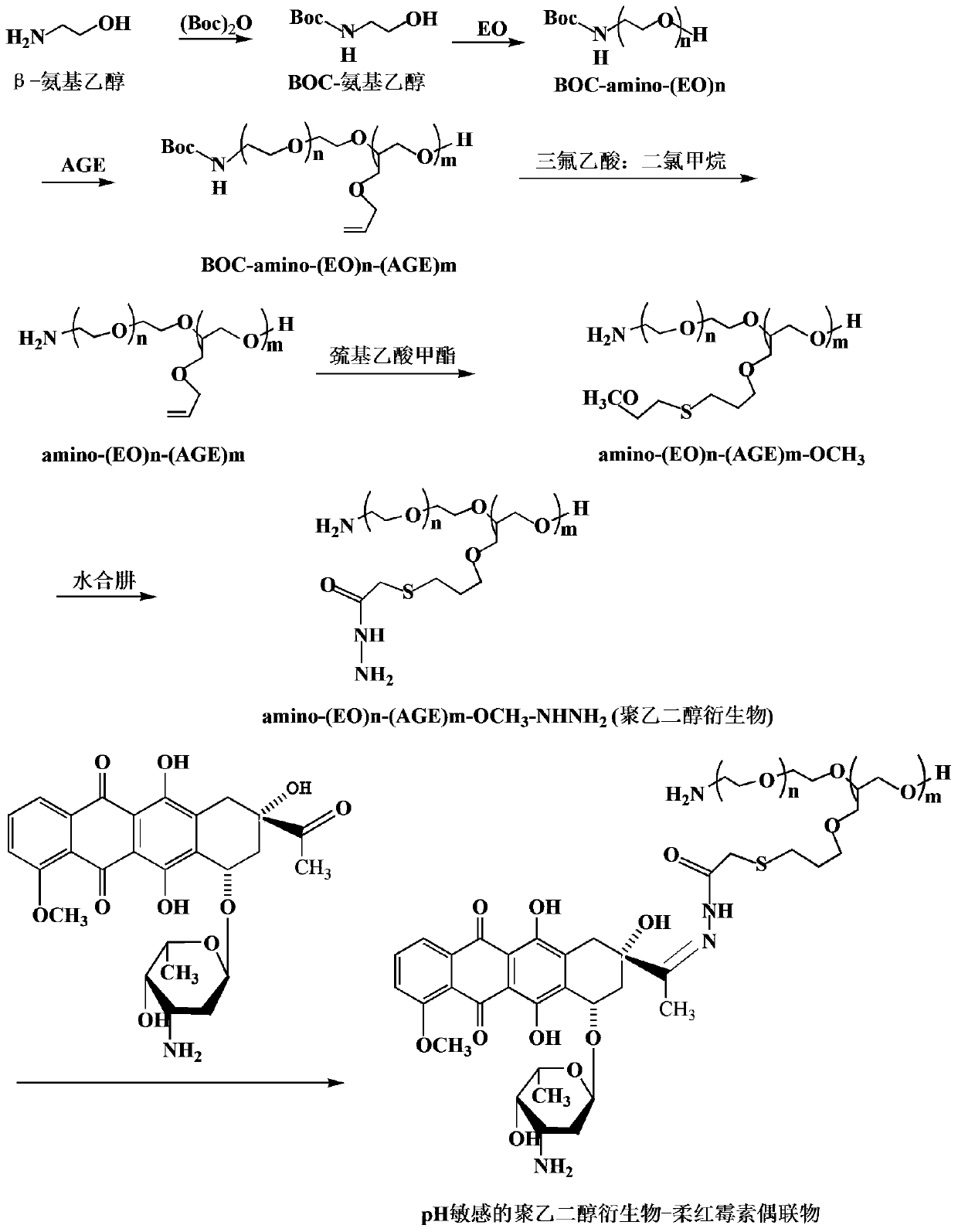

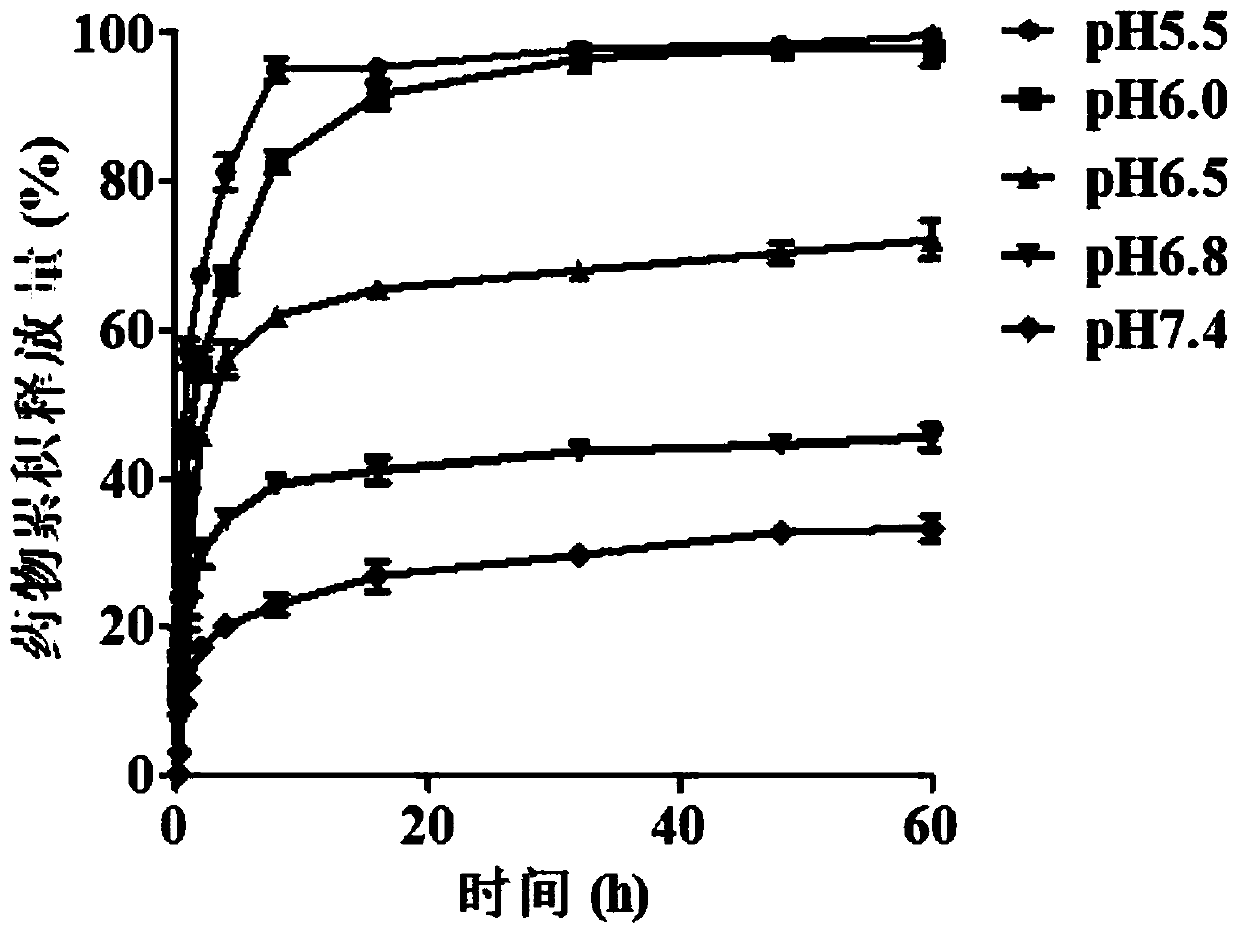

Application of pH sensitive polyethylene glycol derivative and small molecule drug conjugate polymer micelle in inflammatory targeting drug delivery system

ActiveCN106139159AAvoid the defects of being degraded in advanceIncrease concentrationOrganic active ingredientsAntipyreticDiseasePolyethylene glycol

The invention provides an application of pH (potential of hydrogen) sensitive polyethylene glycol derivative and small molecule drug conjugate in a formula (I) and polymer micelle thereof as an inflammatory targeting delivery system and a preparation method of the pH sensitive polyethylene glycol derivative and small molecule drug conjugate. A portion B includes a small molecule drug D with inflammatory disease treating activity, and a portion A includes a polyethylene glycol derivative carrier system. The pH sensitive polyethylene glycol derivative and small molecule drug conjugate polymer micelle has good inflammatory targeting property, the concentration of the drug in the portion B at a low-pH inflammatory site can be remarkably increased, or staying time of the drug at the low-pH inflammatory site can be prolonged, or the anti-inflammatory effect of the drug can be enhanced.

Owner:SICHUAN UNIV

Preparation method for carbon extraction and manganese consercation in medium-manganese high-phosphorus molten steel in converter steel making

ActiveCN109161633AReduce re-oxidationPrevent splashManufacturing convertersProcess efficiency improvementSmelting processManganese

The invention discloses a preparation method for carbon extraction and manganese consercation in medium-manganese high-phosphorus molten steel (Mn is 0.70-0.90wt%, Si is 0.25-0.45wt%, P is 0.120-0.220wt% and S is less than or equal to 0.040wt%) in converter steel making. By adopting the preparation method, processes such as slag retention operation, continuous casting slag application, little slagsmelting, constant pressure gun conversion operation in the smelting process, lowest gun position pressing operation in primary pouring of a converter, and slag wash of whole-process steel discharge,are integrated and created, rapid slag formation in the smelting process is promoted, smelting reaction kinetic and thermodynamic conditions are improved, excellent slagging and phosphorus removal effects are achieved, molten steel and slag splashing in the smelting process is avoided, a MnO allocation concentration is effectively increased, reduction of the MnO at the medium stage of smelting ispromoted, secondary oxidation of Mn in molten steel at the later smelting stage is reduced, furthermore, the content of residual Mn in the molten steel at a final point is remarkably increased (0.25-0.40wt%), the addition amount of a manganese alloy in a deoxidation alloying process is reduced, the steel making alloy consumption and alloying cost can be remarkably reduced, and the market competitiveness of products can be improved.

Owner:WUKUN STEEL

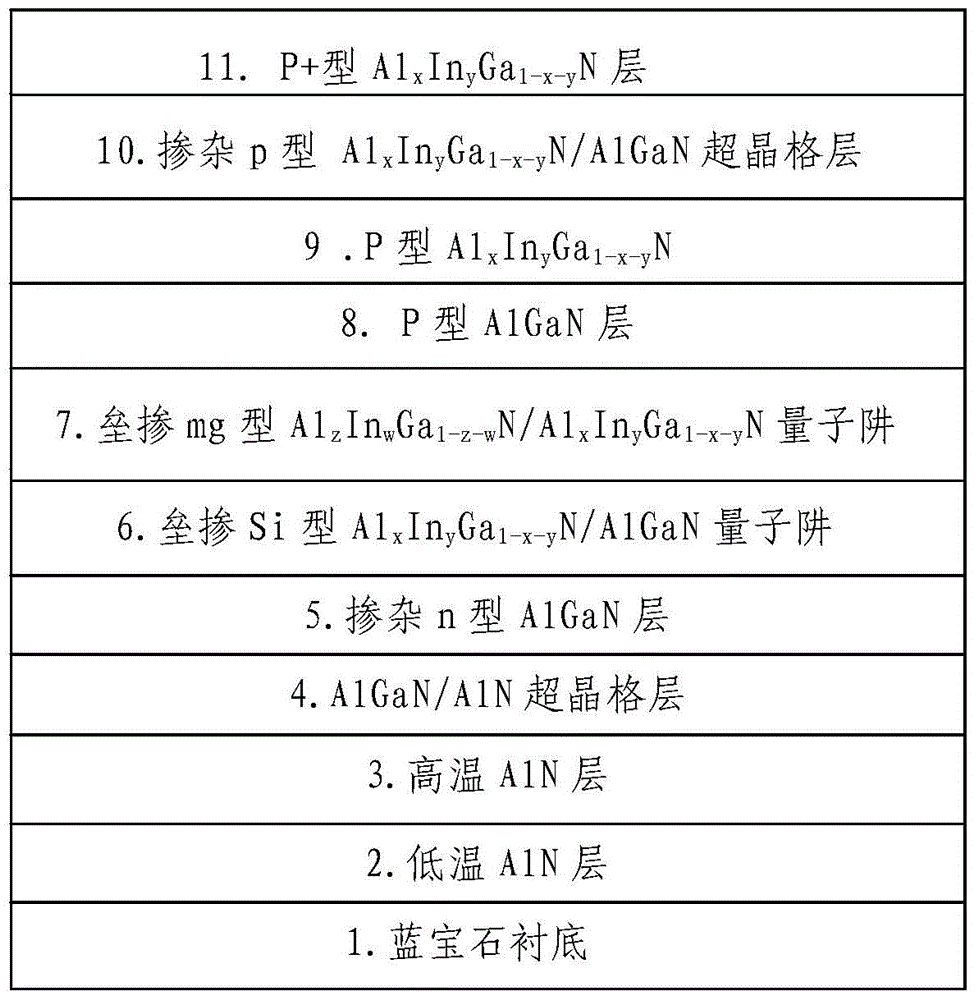

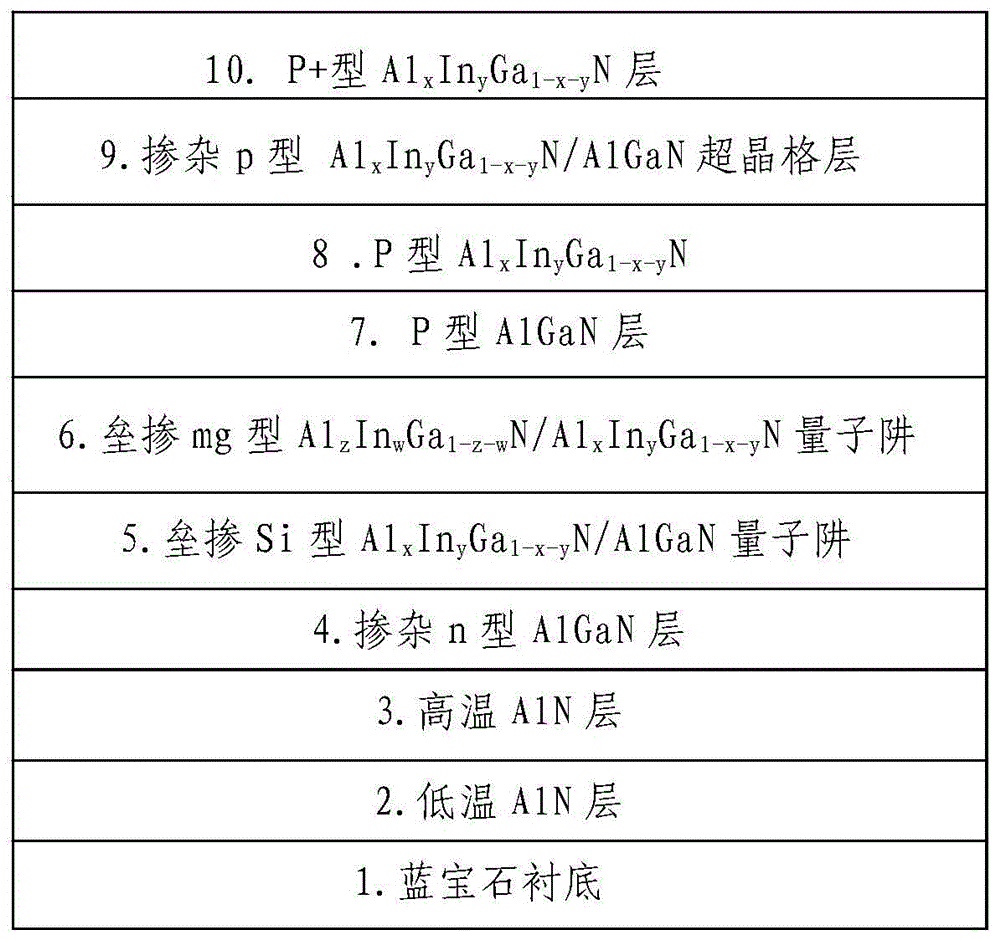

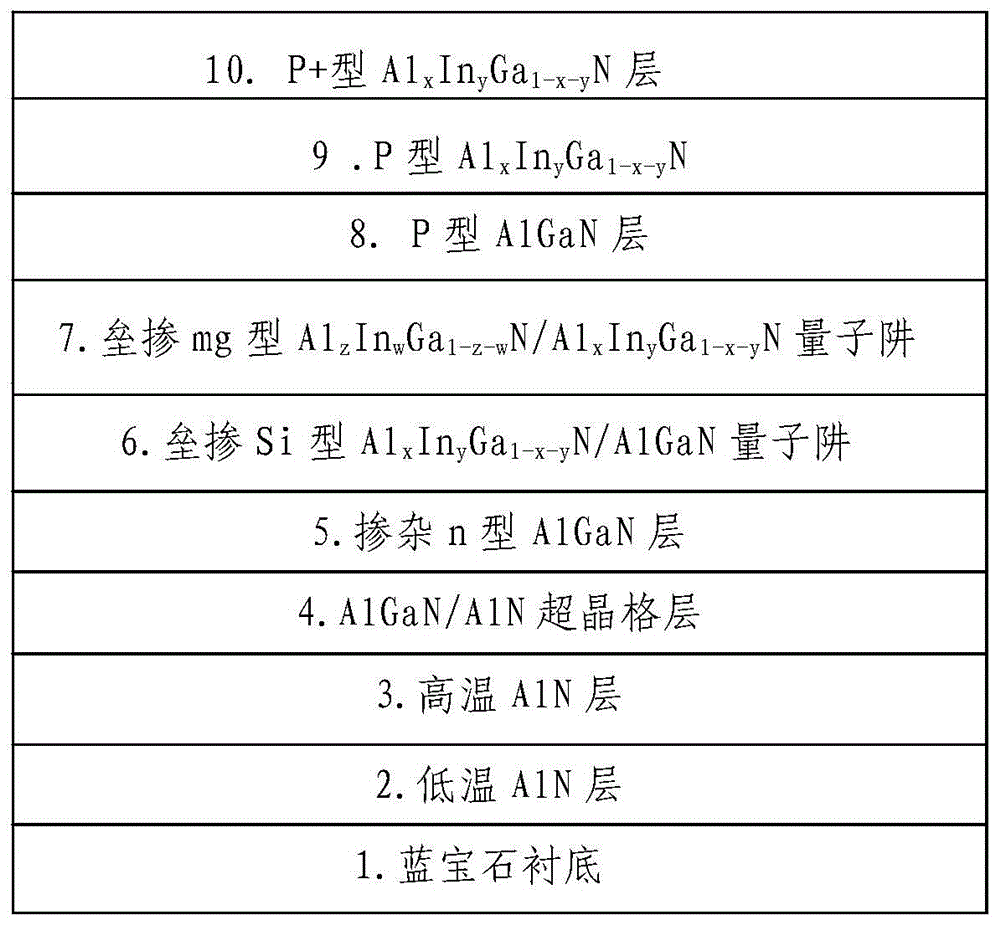

A kind of epitaxial growth method of high-efficiency ultraviolet LED

The invention provides a new method for epitaxial growth of an ultraviolet LED. By the adoption of the method for epitaxial growth of the ultraviolet LED, the growth difficulty can be greatly lowered, and the radiant power of the ultraviolet LED is greatly increased. An AlGaN / AlxInyGa1-x-y layer is grown for a plurality of periods, wherein x, y, z and w meet the following requirements for x<z<1, w<y<1, 0<z+w<1 and 0<x+y<1. Through the component ratio relationship of Al, In and Ga, all components of an AlxInyGa1-x-yN layer can be well matched with lattices of the AlGaN layer, stress is reduced, the crystalline quality of AlGaN and AlxInyGa1-x-y materials is improved, and threading dislocation can also be avoided.

Owner:西安利科光电科技有限公司

A converter smelting method for increasing residual manganese in molten steel with medium, high manganese, high phosphorus and low silicon

ActiveCN109097522BIncrease the residual Mn contentReduce back phosphorusManufacturing convertersProcess efficiency improvementSteelmakingSmelting process

Owner:WUKUN STEEL

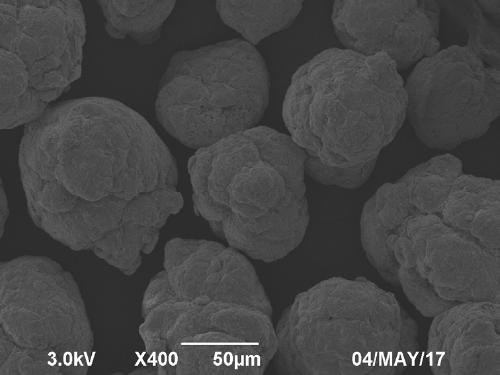

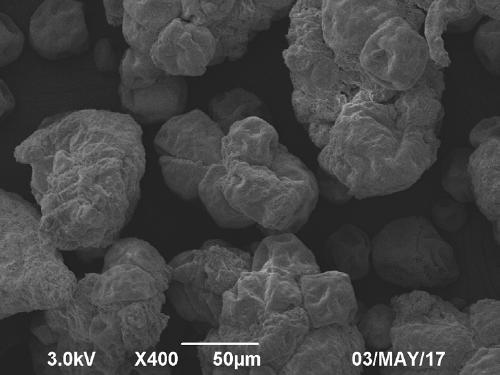

A kind of preparation method of polyvinyl chloride resin special for chlorination

The invention relates to a preparation method of special polyvinyl chloride resin for chlorination. The method comprises the following steps: uniformly premixing a quality agent and vinyl chloride monomer in advance, adding deionized water, a dispersing agent I, a dispersing agent II, a PH regulator, a heat stabilizer, a chain transfer agent and an initiator into a polymerization reactor to perform polymerization reaction, ensuring that the quality agent adopts water soluble polyvinyl alcohol with low polymerization degree and low alcoholysis degree, and the dispersing agent I adopts grafted polyvinyl alcohol copolymer resin, and adopting special production technology to premix the quality agent and the vinyl chloride monomer in advance. The special polyvinyl chloride resin for chlorination, prepared through the method, has the advantages that the particle surface films are less or no film exists, the resin particle shapes are regular, the structure is loose, pore distribution is uniform, the degree of concentration of resin particle sizes is high, polymerization reaction is stable during production, and the quality repeatability of all batches of resin is good, and the special polyvinyl chloride resin is particularly applicable to the preparation of chlorinated polyvinyl chloride resin through chlorination.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

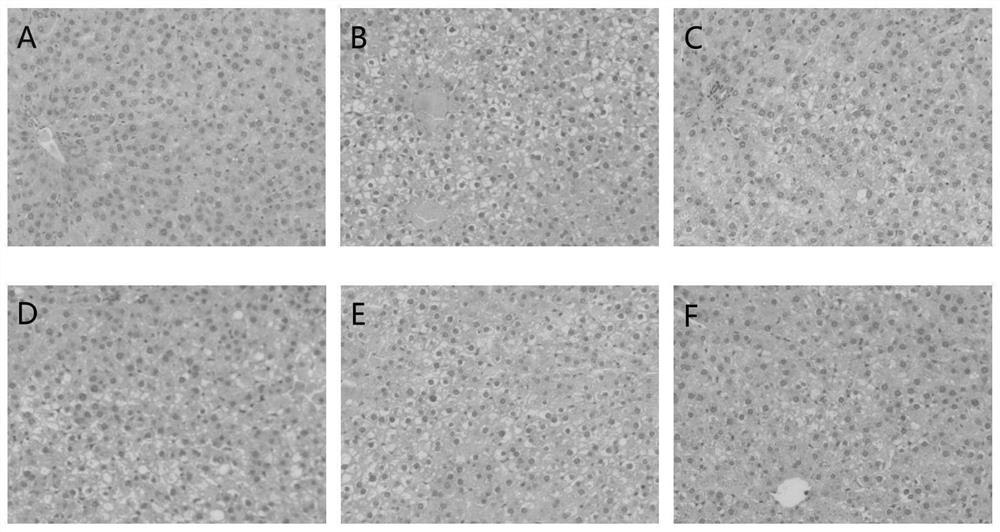

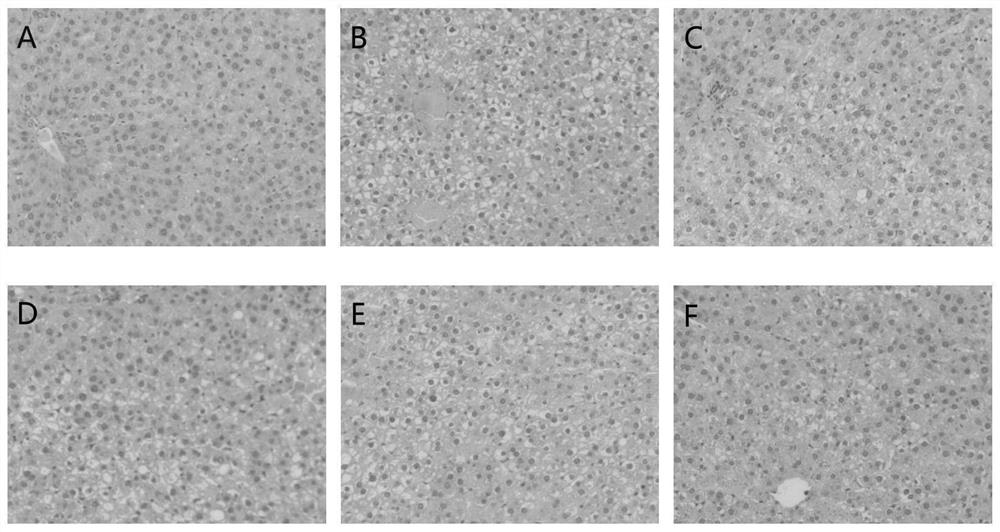

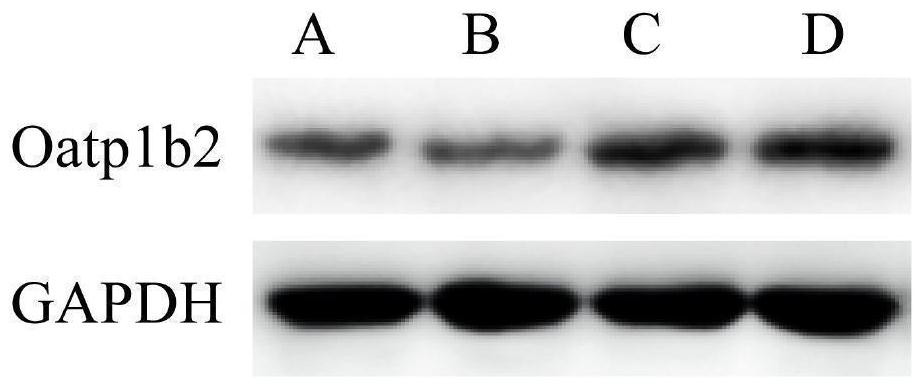

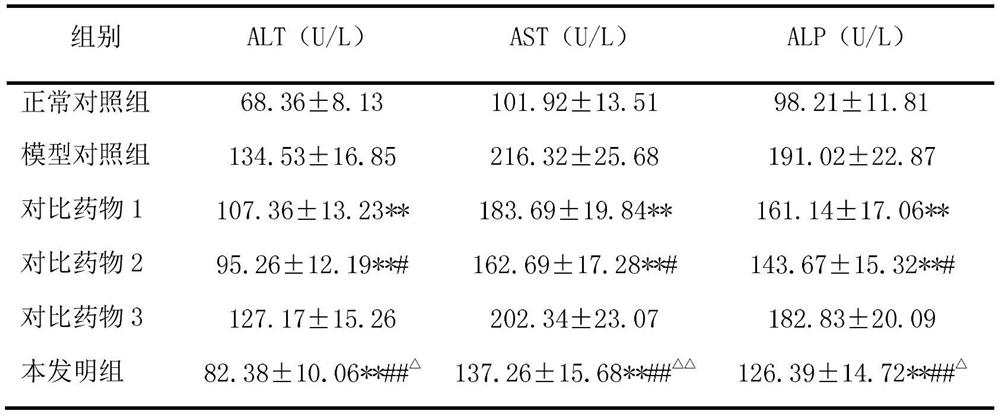

A traditional Chinese medicine composition containing achyranthes bidentata for treating non-alcoholic fatty liver of yin deficiency and excessive heat, and its preparation method and application

ActiveCN113274453BIncrease distribution concentrationGood synergyDigestive systemPlant ingredientsTherapeutic effectYin deficiency

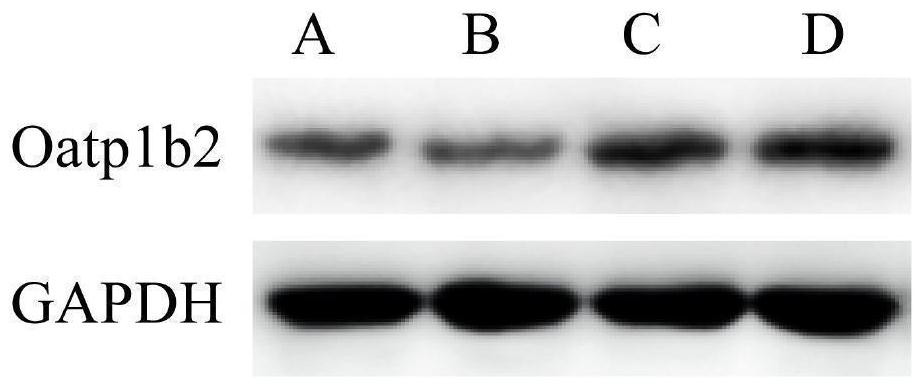

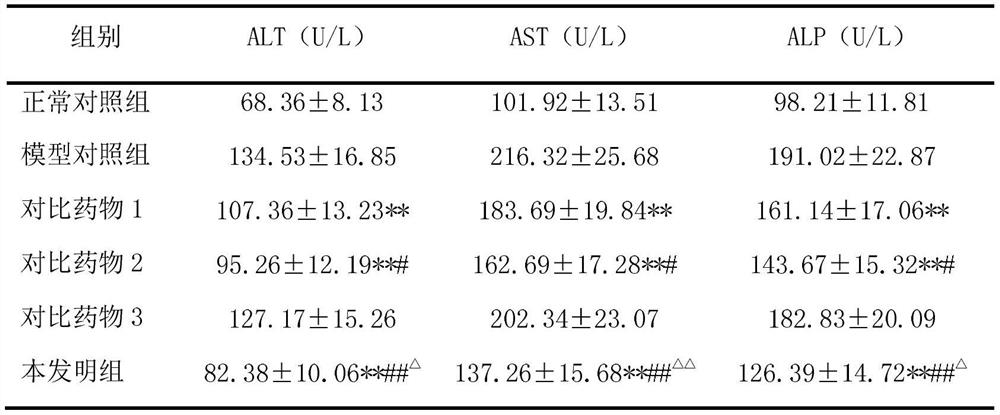

The invention discloses a traditional Chinese medicine composition containing Achyranthes bidentata for treating non-alcoholic fatty liver of yin deficiency and excessive heat type, and its preparation method and application. The composition includes the following raw materials in parts by weight: Achyranthes bidentata 6~ 18 parts, 12-30 parts of Ophiopogon japonicus, 6-25 parts of Anemarrhena, 15-45 parts of Commelina, 9-27 parts of Dijincao, 3-12 parts of Schisandra, 12-24 parts of Tianjihuang, Daidaihua 10-20 parts, 6-15 parts of lotus leaf, 6-12 parts of kapok, 3-12 parts of Dabupi. The inventors of the present invention have found through research that the composition composed of Ophiopogon japonicus, Anemarrhena, Commelina, Dijincao, Schisandra, Tianjihuang, Daidaihua, lotus leaf, kapok, and Dabupi is effective against yin deficiency and heat. Sheng non-alcoholic fatty liver has a certain therapeutic effect. When used in combination with Achyranthes bidentata, Achyranthes bidentata can increase the distribution concentration of active ingredients of other drugs in liver tissue by up-regulating the expression of Oatp1b2, resulting in a better synergistic effect.

Owner:THE CHINESE TRADITIONAL HERB MEDICINE RES INST HENAN PROV

Disodium adenosine triphosphate external medicine for preventing and treating myopia as well as preparation method and application of disodium adenosine triphosphate external medicine

PendingCN114569546AEliminate or reduce astigmatismImprove distance visionOrganic active ingredientsSenses disorderMuscular asthenopiaAdenosine

The invention discloses an adenosine disodium triphosphate external medicine for preventing and treating myopia as well as a preparation method and application of the adenosine disodium triphosphate external medicine. The externally applied medicine comprises an adenosine disodium triphosphate eye drop and an adenosine disodium triphosphate eye patch, wherein the adenosine disodium triphosphate eye patch comprises an eye patch liquid and a spunlace non-woven fabric for the eye patch; the invention further discloses a medicine for preventing and treating myopia. The medicine comprises an oral medicine and an external medicine, the disodium adenosine triphosphate eye drop and the disodium adenosine triphosphate eye patch liquid both comprise disodium adenosine triphosphate, L-methionine and a pH regulator. According to the disodium adenosine triphosphate eye patch, the prevention and treatment effects of disodium adenosine triphosphate on eye asthenopia, myopia and myopic amblyopia are effectively exerted, and side effects caused in the use process are effectively avoided. According to the invention, a lengthened part of the ocular axis can be shortened, astigmatism of a crystalline lens can be removed or relieved, the distant vision of naked eyes can be improved, the functions of optic nerves and retina can be improved, and some asthenopia and systemic discomfort symptoms caused by myopia can be relieved.

Owner:裴丽林

A kind of preparation method of converter smelting high manganese, low silicon and high phosphorus iron water to extract carbon and preserve manganese

ActiveCN109097521BPrevent splashIncrease distribution concentrationManufacturing convertersProcess efficiency improvementSteelmakingSmelting process

The invention discloses a preparation method of a preparation method of C-extracted and Mn-kept molten steel (Mn 1.20wt%-1.50wt%, Si smaller than or equal to 0.20wt%, 0.130wt%-0.180wt% of P) with high-Mn, low-Si and high-P molten iron for converter smelting. Integrated innovation is performed on processes such as slag remaining operation, little slag smelting, constant-pressure lance change operation in the smelting process, converter-lowest lance position press operation, slag washing in the tapping process and bottom argon blowing in the whole process, the smelting reaction kinetics and thermodynamic conditions are optimized, good slagging dephosphorization and desulfurization effects are obtained, molten steel and slag splashing in the smelting process are avoided, the distribution concentration of MnO in slag is effectively increased, reduction of MnO in slag in the middle period of smelting, reoxidation of Mn in molten steel in the later period of smelting is reduced, the residualMn content (0.40wt%-0.60wt%) in end molten steel is significantly increased, the addition amount of a manganese alloy in the deoxidation alloying process is substantially reduced, the steelmaking alloy consumption and alloying cost is reduced significantly, and the market competitiveness of steel products is improved.

Owner:WUKUN STEEL

Use of Polyethylene Glycol Derivatives-Small Molecule Drug Conjugate Polymer Micelle in Inflammation Targeted Drug Delivery System

ActiveCN106139159BImprove stabilityAchieve long cycleOrganic active ingredientsAntipyreticDrug conjugationPolyethylene glycol

The invention provides an application of pH (potential of hydrogen) sensitive polyethylene glycol derivative and small molecule drug conjugate in a formula (I) and polymer micelle thereof as an inflammatory targeting delivery system and a preparation method of the pH sensitive polyethylene glycol derivative and small molecule drug conjugate. A portion B includes a small molecule drug D with inflammatory disease treating activity, and a portion A includes a polyethylene glycol derivative carrier system. The pH sensitive polyethylene glycol derivative and small molecule drug conjugate polymer micelle has good inflammatory targeting property, the concentration of the drug in the portion B at a low-pH inflammatory site can be remarkably increased, or staying time of the drug at the low-pH inflammatory site can be prolonged, or the anti-inflammatory effect of the drug can be enhanced.

Owner:SICHUAN UNIV

Bicyclo-ethanol submicron emulsion and preparation method thereof

ActiveCN101524329BImprove solubilityGood chemical stabilityDigestive systemEmulsion deliveryOrganosolvOil phase

The invention discloses a bicyclo-ethanol submicron emulsion and a preparation method thereof. the preparation method comprises the steps of dissolving bicyclo-ethanol and emulsifying agent in an oil phase, adding an assistant for emulsifying agent, a stabilizing agent, other additive and a water phase, adopting a cutting dispersing and high-pressure homogeneous emulsification process to prepare an oil-in-water(O / W) submicron emulsion with the average grain diameter below 500 nm and drug loading dosage between 0.01mg / ml and 5mg / ml. The bicyclo-ethanol submicron emulsion is injected through vein and used for treating medium and serious hepatitis. The prepared submicron emulsion does not contain solubilizer such as Tween-80 or organic solvent, can be mixed with glucose injection, physiological saline or distilled water according to random proportion, and can not easily generate insoluble particulates when stored, used or matched with other components, thereby having high security and good stability. The invention also relates to various preparations of the bicyclo-ethanol submicron emulsion.

Owner:INST OF MATERIA MEDICA CHINESE ACAD OF MEDICAL SCI +1

External taurine medicine for treating myopia as well as preparation method and application of external taurine medicine

PendingCN114146075AEasy to useGood treatment effectHeavy metal active ingredientsSenses disorderPharmaceutical drugEthyl ester

The invention discloses a taurine external medicine for treating myopia as well as a preparation method and application thereof. The external use medicine comprises taurine eye drops and taurine eye patches. The taurine eye pad comprises taurine eye pad liquid and spunlace non-woven fabric for the eye pad. Each of the taurine eye drops and the taurine eye patch liquid comprises taurine, boric acid, anhydrous borax, ethylparaben and ethanol. The invention further discloses a medicine for treating myopia. The medicine comprises an external medicine and an internal medicine. When the taurine external use medicine is applied to the outside of eyes, the absorption of taurine in eye tissues can be obviously promoted through a skin hydration method, the distribution concentration of taurine in the eye tissues is greatly improved, and eye diseases caused by taurine metabolic disorder are effectively treated. And injection is not needed, and the eye patch can be directly applied to the eyes conveniently and quickly and is convenient to carry.

Owner:裴丽林

Micro powder jet mill

ActiveCN106179667BGuaranteed continuityGuaranteed uniformityGas current separationGrain treatmentsParticle-size distributionAirflow

The invention relates to a micro-powder airflow mill. The micro-powder airflow mill is characterized in that an adjusting gasket and a sorting wheel are arranged on a motor spindle; a motor base is fixedly connected to an upper cover; the upper cover is fixedly connected to a supporting plate of a mill chamber outer shell; the periphery of the motor base is connected with a plurality of air connectors; a mill chamber inner shell is arranged in the mill chamber outer shell; a cavity of the mill chamber inner shell serves as a mill chamber; the bottom of a nozzle fixing disc of the mill chamber inner shell is fixedly connected with a plurality of nozzles; the nozzle fixing disc of the mill chamber inner shell is arranged on a bottom disc; the lower end of the bottom disc is fixedly connected with auxiliary air connectors; the multiple auxiliary air connectors are fixedly connected to an auxiliary air connector fixing seat; a discharging bush is arranged in the center of the nozzle fixing disc and the center of the bottom disc; a clearance is arranged between the end face of the sorting wheel and the end face of the nozzle fixing disc; a feeding mechanism and an air inlet pipe are fixedly connected to the outer circumference face of the mill chamber outer shell; and the lower end of the discharging bush is connected with a finished product discharge opening. The micro-powder airflow mill is reasonable in structure, the material particle size distribution concentration ratio can be effectively increased, product quality is good, and cost is low.

Owner:吉林市新大科机电技术有限责任公司

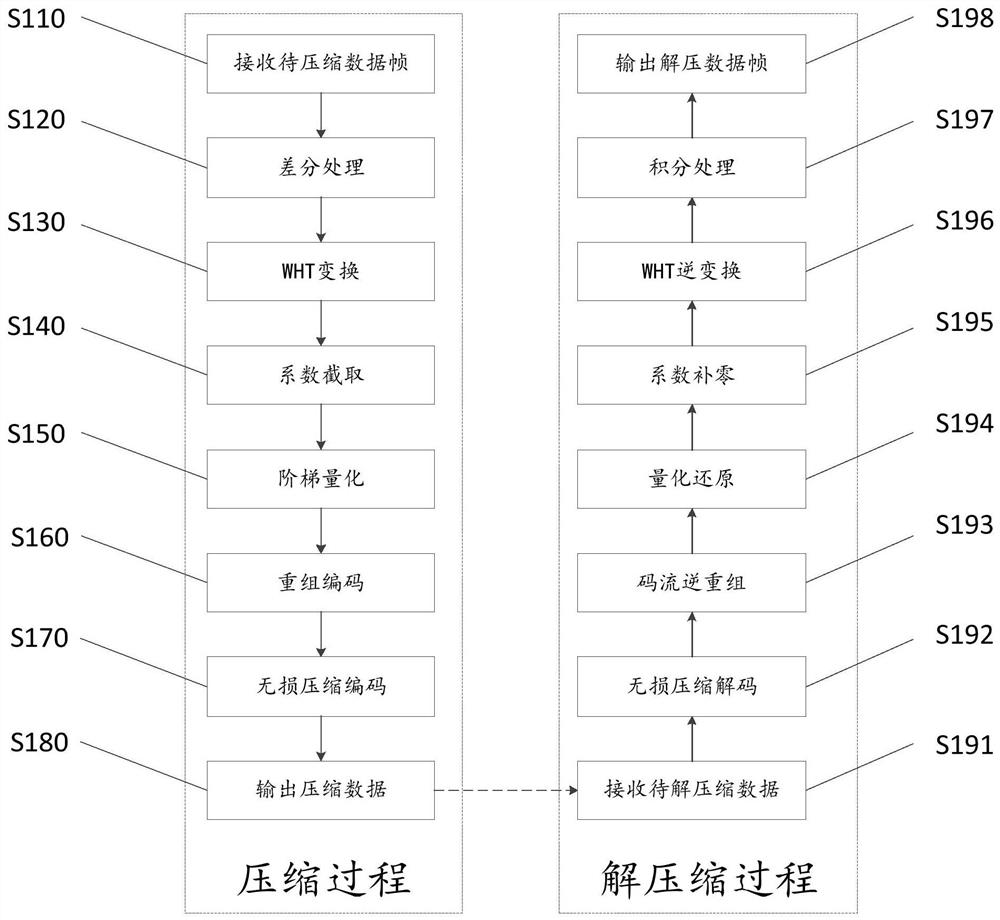

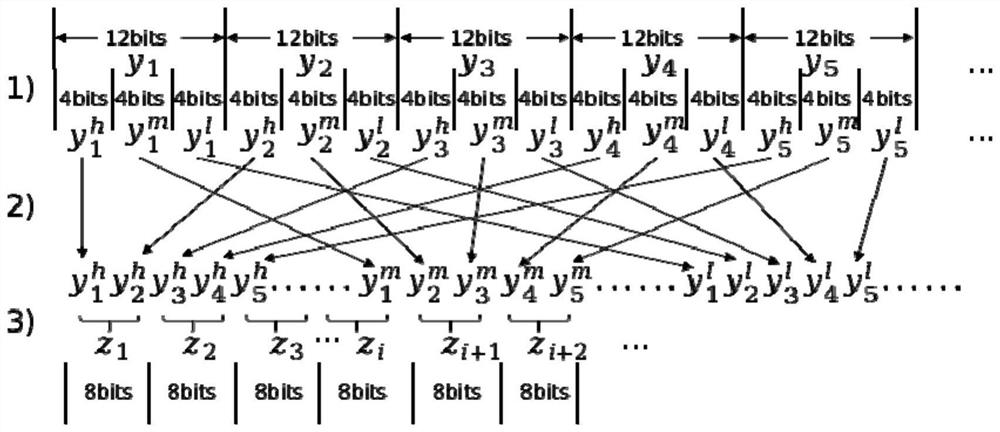

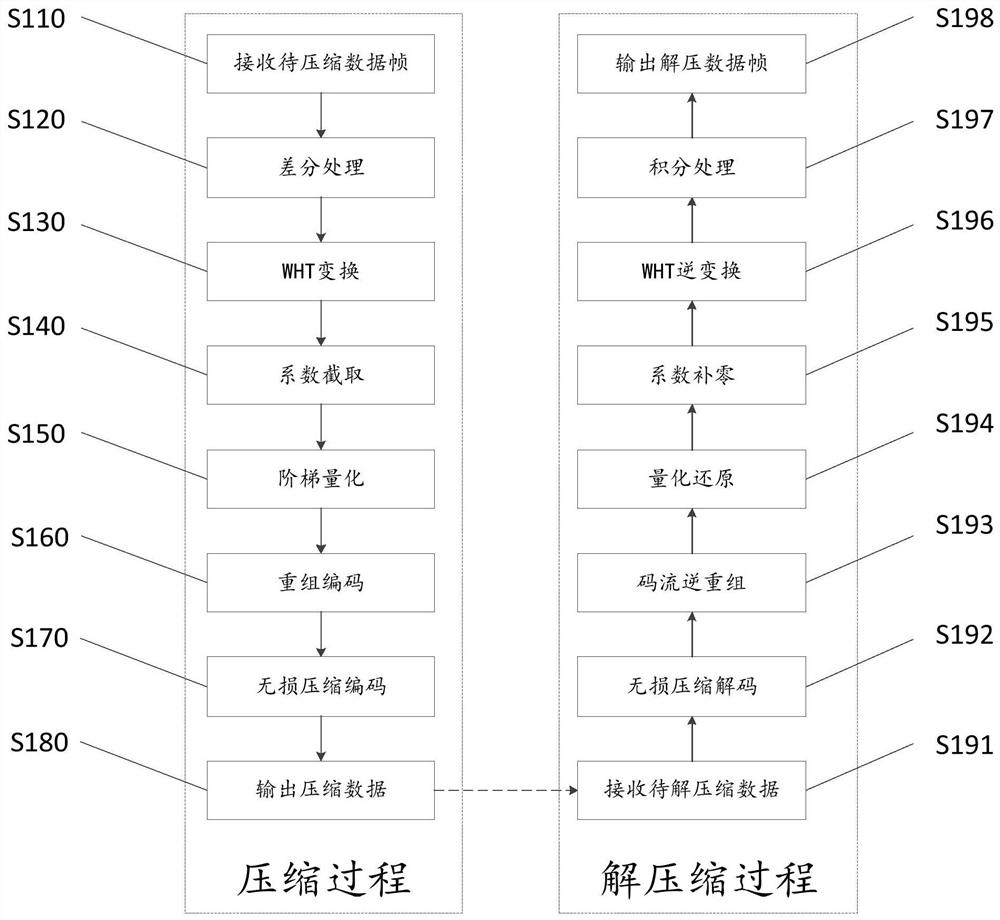

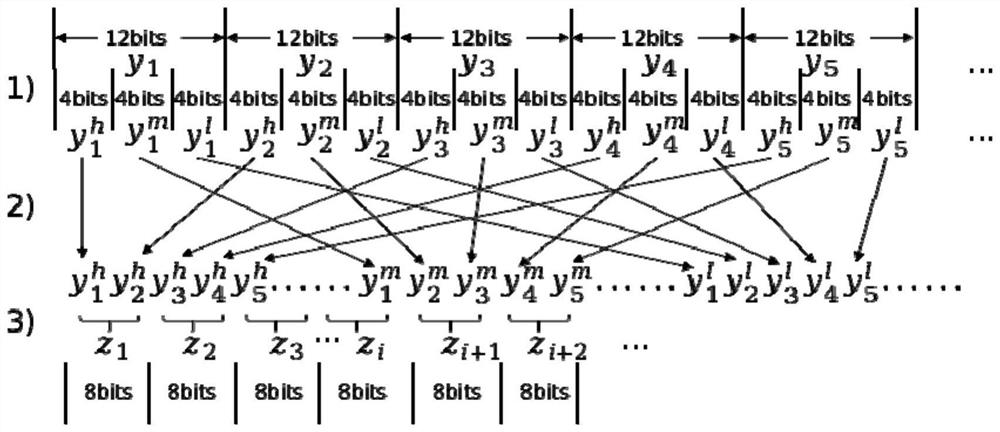

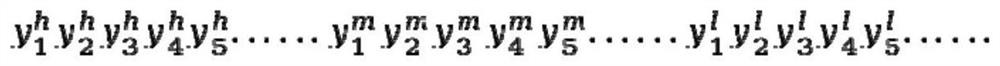

A method for compressing and decompressing data of this frame with high compression rate and high reducibility

ActiveCN111918062BGood continuityIntegrity guaranteedDigital video signal modificationData compressionStreaming data

The invention discloses a method for compressing and decompressing data of this frame with high compression rate and high reductibility, including a compression method and a decompression method; The coefficient interception is performed on the WHT transformed data, the stepwise quantization is performed on the retained data after interception, the bit stream recombination is performed on the quantization result, and the byte stream data after the bit stream recombination is obtained, and then the byte stream data is compressed by compression coding. , get the final compressed data and output it. The decompression method is a reverse operation to obtain decompressed data. The method for compressing and decompressing data of this frame of the present invention has the characteristics of high compression rate and high reduction rate. By simplifying the data processing unit, the compression rate and reducibility are improved, thereby reducing the occupied capacity in the process of storage and transmission, and at the same time improving the transmission rate. speed, shorten the transmission time, and ensure the real-time and stability of the data.

Owner:上海定九康科技股份有限公司

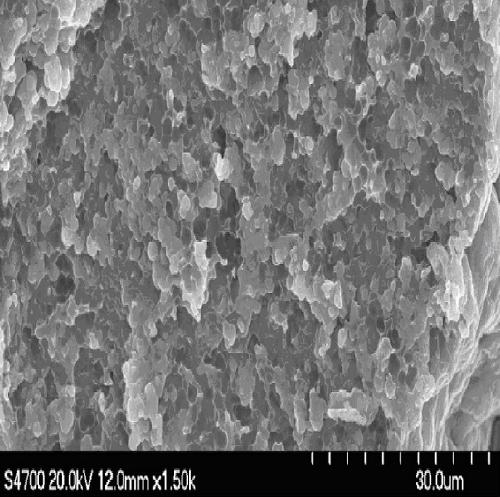

A kind of anti-hardening cotton wool preparation method

ActiveCN107540635BImprove uniformityIncrease distribution concentrationOrganic chemistryPhosphatePERMANGANATE ION

The invention relates to a method for preparing anti-hardening cotton wool, which belongs to the technical field of pesticide synthesis. In order to solve the existing problem of short storage time and easy agglomeration, a method for preparing cotton wool that is resistant to hardening is provided. The method includes adding a permanganate aqueous solution to the carbon disulfide solution for pretreatment, layering, and collecting the pretreated Carbon disulfide solution; react the pretreated carbon disulfide solution with concentrated methylamine aqueous solution to obtain an aqueous solution containing N-methyldithiocarbamic acid; in the presence of phosphate, amphoteric surfactant and EDTA, react with formaldehyde to obtain The amount of phosphate added is 1.0%-1.5% of the mass of formaldehyde, and the mass ratio of phosphate: amphoteric surfactant: EDTA is 1:0.5-0.6:0.01-0.02. The invention can increase the uniformity and distribution concentration of the particles and increase the compaction resistance of the cotton wool particles, so as to have the effect of high fluidity.

Owner:浙江大鹏药业股份有限公司

A preparation method for extracting carbon and preserving manganese from manganese-high-phosphorus iron in converter smelting

ActiveCN109161633BReduce re-oxidationPrevent splashManufacturing convertersProcess efficiency improvementSteelmakingSmelting process

The invention discloses a preparation method for carbon extraction and manganese consercation in medium-manganese high-phosphorus molten steel (Mn is 0.70-0.90wt%, Si is 0.25-0.45wt%, P is 0.120-0.220wt% and S is less than or equal to 0.040wt%) in converter steel making. By adopting the preparation method, processes such as slag retention operation, continuous casting slag application, little slagsmelting, constant pressure gun conversion operation in the smelting process, lowest gun position pressing operation in primary pouring of a converter, and slag wash of whole-process steel discharge,are integrated and created, rapid slag formation in the smelting process is promoted, smelting reaction kinetic and thermodynamic conditions are improved, excellent slagging and phosphorus removal effects are achieved, molten steel and slag splashing in the smelting process is avoided, a MnO allocation concentration is effectively increased, reduction of the MnO at the medium stage of smelting ispromoted, secondary oxidation of Mn in molten steel at the later smelting stage is reduced, furthermore, the content of residual Mn in the molten steel at a final point is remarkably increased (0.25-0.40wt%), the addition amount of a manganese alloy in a deoxidation alloying process is reduced, the steel making alloy consumption and alloying cost can be remarkably reduced, and the market competitiveness of products can be improved.

Owner:WUKUN STEEL

A preparation method for extracting carbon and preserving manganese by converting high-manganese, high-sulfur, and high-phosphorus iron into hot water

ActiveCN109161635BReduce re-oxidationIncrease distribution concentrationManufacturing convertersSteelmakingSmelting process

Owner:WUKUN STEEL

Traditional Chinese medicine composition containing guiding drug achyranthes bidentata for treating Yin deficiency and heat excess type non-alcoholic fatty liver disease and preparation method and application thereof

ActiveCN113274453AIncrease distribution concentrationGood synergyDigestive systemPlant ingredientsYin deficiencyRadix Ophiopogonis

The invention discloses a traditional Chinese medicine composition containing a guiding drug achyranthes bidentata for treating a Yin deficiency and heat excess type non-alcoholic fatty liver disease and a preparation method and application thereof. The composition is prepared from, by weight, 6-18 parts of achyranthes bidentata, 12-30 parts of radix ophiopogonis, 6-25 parts of rhizoma anemarrhenae, 15-45 parts of dayflower, 9-27 parts of humifuse euphorbia herb, 3-12 parts of schisandra chinensis, 12-24 parts of hypericum japonicum, 10-20 parts of seville orange flowers, 6-15 parts of lotus leaves, 6-12 parts of common bombax flowers and 3-12 parts of pericarpium arecae. Research shows that the composition prepared from radix ophiopogonis, rhizoma anemarrhenae, dayflower, humifuse euphorbia herb, schisandra chinensis, hypericum japonicum, seville orange flowers, lotus leaves, common bombax flowers and pericarpium arecae has a certain treatment effect on the Yin deficiency and heat excess type non-alcoholic fatty liver disease, when the composition is used in cooperation with achyranthes bidentata, achyranthes bidentata can increase the distribution concentration of other medicine effective ingredients in liver tissue by up-regulating expression of Oatp1b2, and a good synergistic effect is generated.

Owner:THE CHINESE TRADITIONAL HERB MEDICINE RES INST HENAN PROV

A converter smelting method for increasing residual manganese in end-point molten steel with medium-high manganese molten iron

ActiveCN109112249BIncrease the residual Mn contentReduce the degree of rephosphorizationManufacturing convertersProcess efficiency improvementSteelmakingSmelting process

The invention discloses a converter smelting method for increasing residual manganese of end point liquid steel by high and medium-manganese hot metal (C, 0.75 to 1.10wt% of Mn, 0.25 to 0.45wt% of Si,0.090 to 0.120wt% of P, and less than or equal to 0.045wt% of S). The converter smelting method has the advantages that the technologies of remaining slag operation, low-alkalinity BaCO3 system slagmanufacturing, fewer-slag smelting, constant-pressure and low-gun level gun change in a smelting process, slag washing in a whole tapping process and the like are adopted, integrated and innovated, soas to optimize the reaction dynamics and thermodynamics conditions of smelting, avoid the splashing of liquid steel and furnace slag in the smelting process, and increase the distribution concentration of slag (MnO) in the smelting process; the good smelting slugging and dephosphorization effect is obtained under the technology conditions of low-alkalinity slag system and fewer slag, and the phosphor return degree of the liquid steel in the later smelting process and the tapping process is effectively reduced; the content of residual Mn in the end point liquid steel is obviously increased to0.38 to 0.50wt%, the adding amount of manganese alloy in the deoxidizing alloy process is greatly reduced, the consumption of steel smelting alloy and the alloying cost are obviously reduced, the improvement of technical and economic indexes in smelting are promoted, and the market competitiveness of a product is improved.

Owner:WUKUN STEEL

Orally-taken chemotherapy tablet for treating stomach cancer

InactiveCN104352518AHas killEasy to killHeavy metal active ingredientsPill deliveryPotassium oxonateSide effect

The invention belongs to the technical field of medicine, and in particular relates to an orally-taken chemotherapy tablet for treating the stomach cancer. The orally-taken chemotherapy tablet is prepared from the following constituents: 55-79 mg of capecitabine, 15.8-19.5 mg of lipoplatin, 16.2-22.4 mg of potassium oxonate, 3.4-5.2 mg of lactose hydrous, 2.5-3.6 mg of magnesium stearate, 2.8-4.2 mg of microcrystalline cellulose, 3.7-4.6 mg of pre-gelatinized starch, and the balance of starch, wherein the total dosage is 150 mg; capecitabine, lipoplatin and potassium oxonate serve as medicinal constituents. The tablet disclosed by the invention is convenient to use, short in course of treatment, effective in treatment, and low in side effect.

Owner:王喜功

Jasminoidin or gardenia total iridoid glycoside liposome preparation

ActiveCN102309449BIncrease distribution concentrationGood treatment effectOrganic active ingredientsAerosol deliveryYolkGenipin

The invention discloses a jasminoidin or gardenia total iridoid glycoside liposome preparation which comprises liposome formed by phospholipid and cholesterol, and asminoidin or gardenia total iridoid glycoside wrapped and loaded in the liposome, wherein the weight ratio of phospholipid to cholesterol is (3:1)-(7:1), preferably 5:1; the weight ratio of asminoidin or gardenia total iridoid glycoside to phospholipid is (1:2)-(1:8), preferably 1:4; and the phospholipid is selected from lecithin, soya lecithin, yolk phospholipid or phosphatidylcholine, preferably soya lecithin or yolk phospholipid. The preparation provided by the invention has the advantages that the contact time of the asminoidin or gardenia total iridoid glycoside and mucosa is prolonged. The liposome preparation can be prepared into a spraying agent after being loaded into a nasal suction apparatus, and is applied in a nasal delivery mode, so that the distribution of the asminoidin or gardenia total iridoid glycoside in brain tissues is effectively improved. The invention also discloses the application of the liposome preparation in preparation of medicaments for treating hypoxic ischemic brain damage diseases.

Owner:JIANGXI UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

A preparation method for extracting carbon and preserving manganese from manganese, low-silicon, and high-phosphorus iron water in converter smelting

ActiveCN109161634BPrevent splashIncrease distribution concentrationManufacturing convertersProcess efficiency improvementSteelmakingSmelting process

The invention discloses a preparation method for carbon extraction and manganese consercation in medium-manganese low-silicon high-phosphorus molten steel (Mn is 0.70-0.90wt%, Si is 0.06-0.15wt%, P is0.130-0.220wt% and S is less than or equal to 0.045wt%) in converter steel making. By adopting the preparation method, processes such as slag retention operation, continuous casting slag application,little slag smelting, constant pressure gun conversion operation in the smelting process, lowest gun position pressing operation in primary pouring of a converter, and slag wash of whole-process steel discharge, are integrated and created, low-silicon molten steel smelting slagging elements and heat sources are increased, rapid slag formation in the smelting process is promoted, smelting reactionkinetic and thermodynamic conditions are improved, excellent slugging and phosphorus removal effects are achieved, molten steel and slag splashing in the smelting process is avoided, a MnO allocationconcentration is effectively increased, reduction of the MnO at the medium stage of smelting is promoted, secondary oxidation of Mn in molten steel at the later smelting stage is reduced, furthermore, the content of residual Mn in the molten steel at a final point is remarkably increased (0.25-0.38wt%), the addition amount of a manganese alloy in a deoxidation alloying process is reduced, the steel making alloy consumption and alloying cost can be remarkably reduced, and the market competitiveness of products can be improved.

Owner:WUKUN STEEL

High-compression-rate and high-reducibility compression and decompression method for frame data

ActiveCN111918062AGood continuityIntegrity guaranteedDigital video signal modificationData compressionStreaming data

The invention discloses a high-compression-rate and high-reducibility local frame data compression and decompression method. The method comprises a compression method and a decompression method. The compression method comprises the following steps: after receiving a to-be-processed data frame, carrying out differential processing, then carrying out WHT transformation on a differential result, carrying out coefficient interception on data subjected to WHT transformation, carrying out stepped quantization on intercepted reserved data, carrying out bit stream recombination on a quantization result, and obtaining byte stream data subjected to bit stream recombination; compressing the byte stream data by using compression coding to obtain final compressed data, and outputting the final compressed data. The decompression method is reverse operation, and decompressed data is obtained. The compression and decompression method of the frame data has the characteristics of high compression rate and high reduction rate, and by simplifying the data processing unit and improving the compression rate and the reducibility, the occupied capacity in the storage and transmission process is reduced, the transmission rate is increased, the transmission time is shortened, and meanwhile, the real-time performance and the stability of the data are guaranteed.

Owner:上海定九康科技股份有限公司

A preparation method for extracting carbon and preserving manganese by converting high-manganese, high-silicon, and high-phosphorus iron into hot water

ActiveCN109055649BPrevent splashPromote reductionManufacturing convertersProcess efficiency improvementSteelmakingSmelting process

The invention discloses a preparation method for carbon extracting and manganese retaining of high-manganese high-silicon and high-phosphorus molten iron through converter smelting, wherein the high-manganese high-silicon and high-phosphorus molten iron comprises, by weight, 1.10-1.50% of Mn, 0.70-1.00% of Si, 0.120-0.170% of P, and 0.035% or the less of S. According to the preparation method, theprocesses such as slag retaining operation, double-slag slag making process, less slag smelting, constant-pressure gun changing operation in the smelting process, converter direct lowest-gun-positiongun pressing operation, slag washing in the steel discharging process, and whole-process bottom argon blowing are adopted and integrally innovated, thus kinetics and thermodynamic conditions of a smelting reaction are optimized, the good smelting slagging dephosphorization and desulfurization effects are obtained, splashing of molten steel and slag in the smelting process is avoided, the distribution concentration in the slag (MnO) is effectively increased, reduction in the slag (MnO) at the smelting medium stage is promoted, re-oxidation of Mn in the molten steel at the smelting later stageis lowered, the end point molten steel residual Mn content (0.35-0.55wt%) is significantly increased, the adding amount of a manganese-series alloy in the deoxidizing alloying process is reduced, steelmaking alloy consumption and the alloying cost are significantly lowered, and the product market competitiveness is improved.

Owner:WUKUN STEEL

A converter smelting method for increasing residual manganese in molten steel with high manganese and high silicon

ActiveCN109136452BIncrease the residual Mn contentIncrease distribution concentrationManufacturing convertersProcess efficiency improvementSteelmakingSmelting process

The invention discloses a converter smelting method for improving end-point molten steel residual manganese in high-manganese and high-silica molten iron (4.40 to 4.80 weight percent of C, 1.10 to 1.30 weight percent of Mn, 0.75 to 1.00 weight percent of Si, 0.085 to 0.105 weight percent of P and 0.015 to 0.035 weight percent of S). According to the method, by adopting technologies such as low alkalinity slag making technology, constant pressure gun change operation at gun position during smelting process, converter inverting gun pressing operation at minimum gun position, steel tapping whole-process wash heat process and carrying out integrated innovation, kinetic and thermodynamic conditions of smelting reaction are optimized, the distribution concentration of the slag (MnO) in the smelting process is improved and better smelting dephosphorizing effect is obtained under the conditions of less slag and a low basicity slag system; moreover, molten steel rephosphorization at the late smelting period and in the steel tapping process is reduced to the maximum extent, so that the residual Mn content (0.48 to 0.65 weight percent) of end-point molten steel is significantly increased, theadding amount of a manganese alloy during the deoxygenation alloying process is significantly reduced, the consumption of steelmaking alloys and the alloying cost are reduced, the improvement of smelting technical and economic indicators is promoted and further the market competitiveness of a product is improved.

Owner:WUKUN STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com