Micro powder jet mill

A kind of air flow and mill technology, which is applied in the direction of separating solid from solid by air flow, solid separation, grain treatment, etc. It can solve the problems of high proportion of superfine powder and low particle size distribution concentration, so as to improve distribution concentration, The effect of ensuring the quality of finished materials, ensuring continuity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The structural design and working principle of the micro-powder jet mill according to the present invention will be described in detail below according to the drawings. It should be understood that the illustrated and described implementations are only for illustration and not limitation, and the exemplary structural design diagram and the combined embodiments of the present invention described below are not intended to exhaust all embodiments according to the present invention.

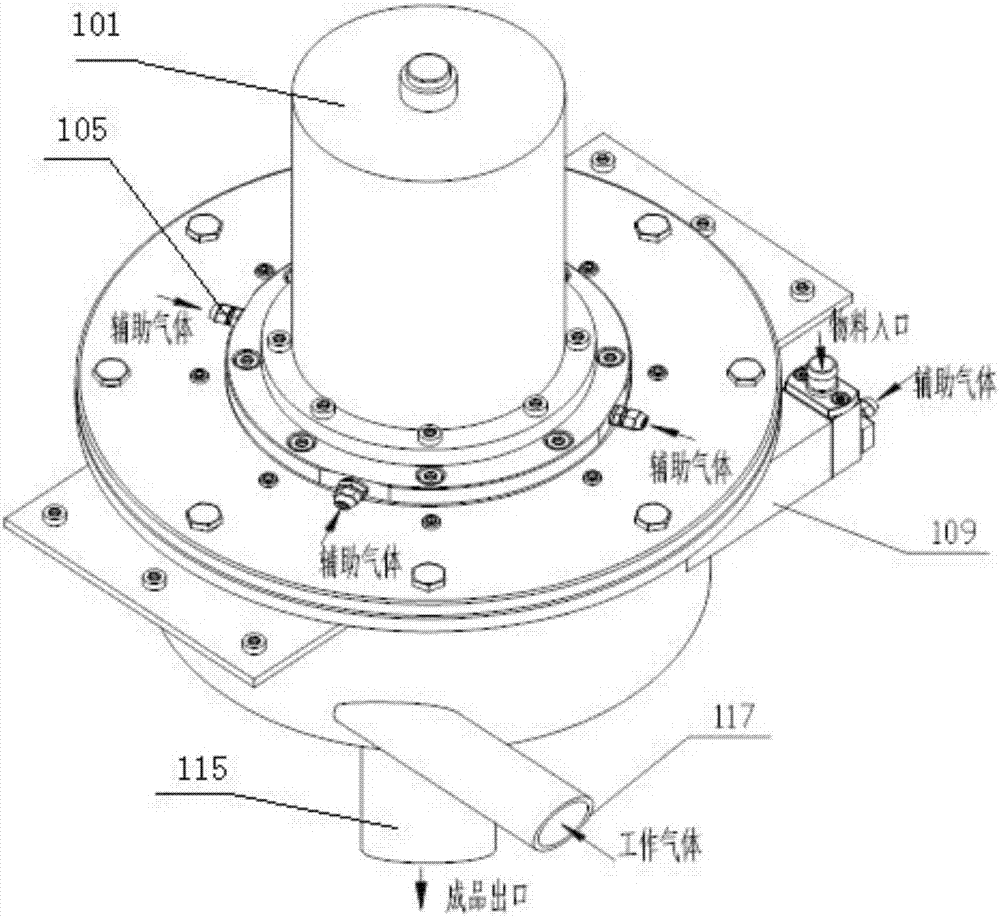

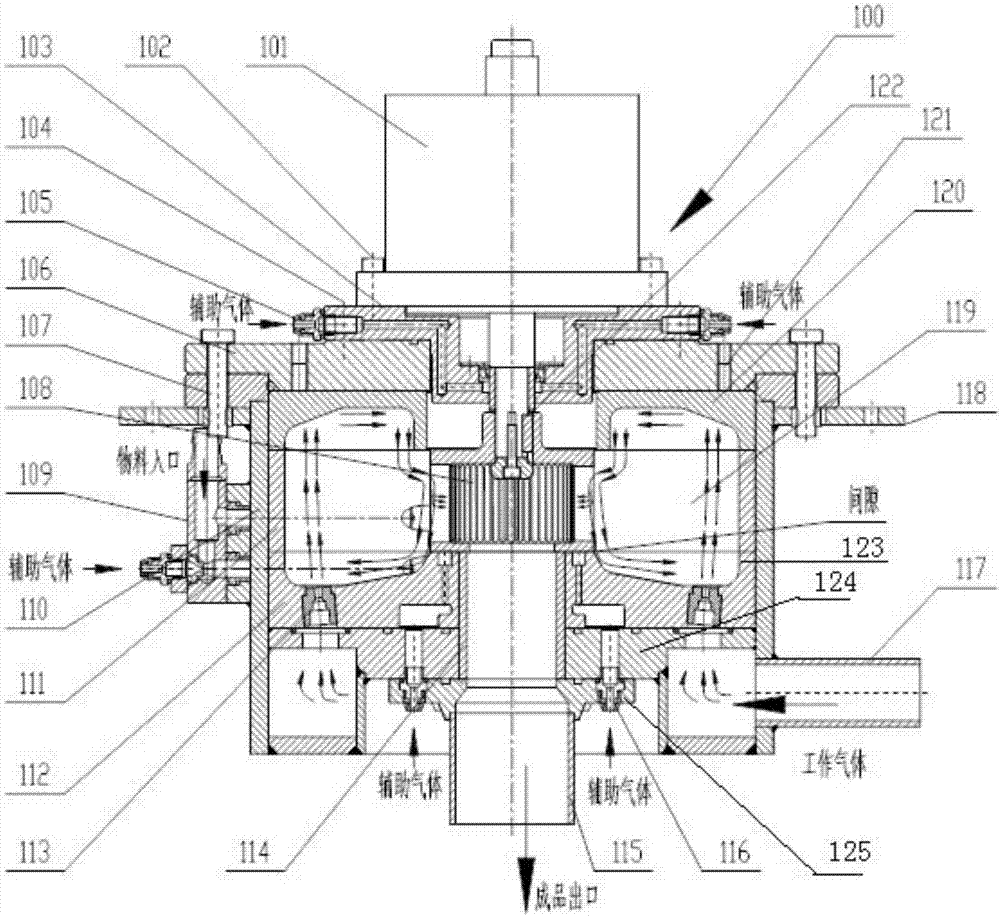

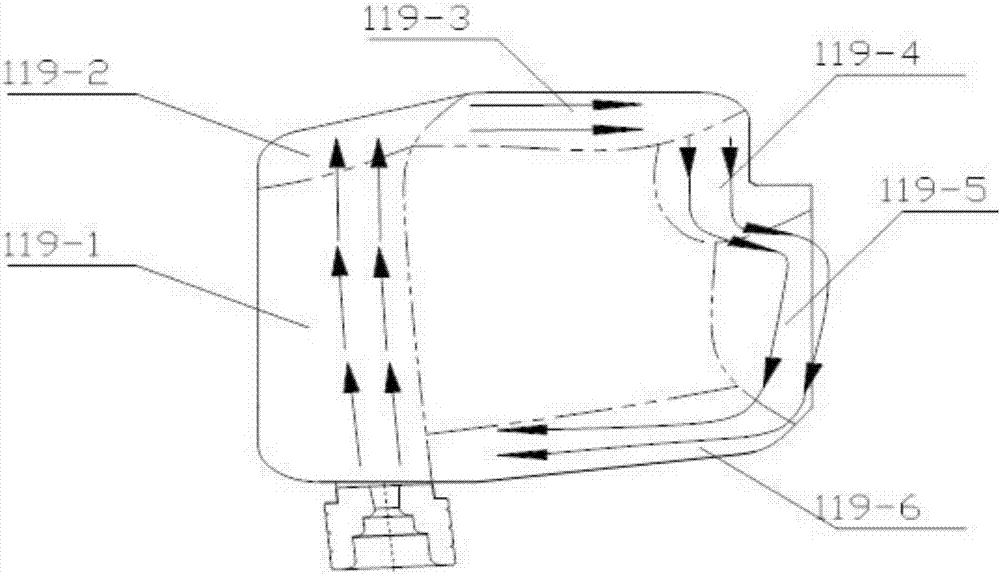

[0032] see Figure 1-Figure 8, the micro powder jet mill 100 of the present invention comprises: the main shaft of the motor 101 is provided with an adjustment pad 122 and a sorting wheel 108 is fixedly connected, the motor 101 is fixedly connected on the motor base 103 by a screw A102, and the motor base 103 is fixed by a screw B104 Connected to the upper cover 106, the upper cover 106 is fixedly connected to the support plate 118 of the outer housing 110 of the mill through screws C107. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com