A kind of production method of anchor rod steel

A production method and technology of bolt steel, applied in the direction of manufacturing converters, metal rolling, etc., can solve problems affecting the stability and safety of bolt steel and other components, difficult to match bolt steel and nut, and not in the same helix. First-class problems, to achieve the effect of improving safety and stability, reducing inclusions, and reducing phosphorus return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A production method of anchor rod steel, comprising the steps of:

[0035] (1) Converter smelting:

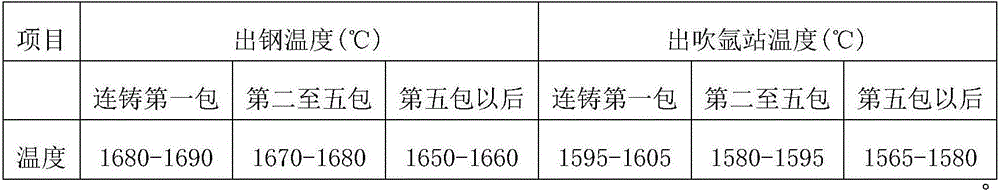

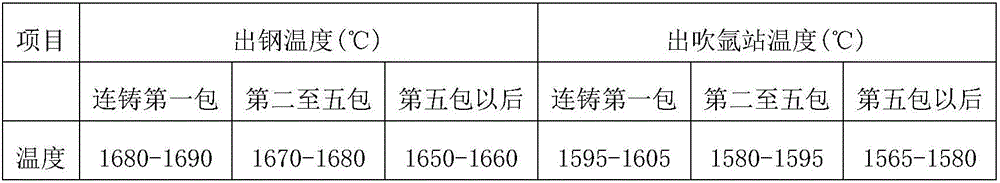

[0036] a. Mix molten iron and steel scrap into a 35t converter or a 100t converter for smelting, control the tapping temperature at 1650-1690°C, and the temperature at the argon blowing station at 1565-1605°C; the diameter of the exposed part of the molten steel during argon blowing is 100-200mm, and the argon blowing time ≥5.5min; the tapping process adopts the double slag blocking tapping process. When tapping starts, use the slag blocking plug to block the tapping hole to prevent slag from flowing out. In the process of tapping, the slag is pressed by a special person, and it is strictly forbidden to drop the slag at the tapping port; the tapping time is ≥ 2.5 minutes, and the steel must be tapped in the same sample; the tapping temperature and the temperature control of the argon blowing station at each stage are shown in Table 2:

[0037] Table 2 Tapping temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com