Agent for treatment of metal surface

A surface treatment agent, alkali metal technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of no effective technology developed, the influence of silver film light reflectivity, and the reduction of light reflection performance, etc., to achieve metal wire welding. Excellent properties, good solder wettability, and excellent safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

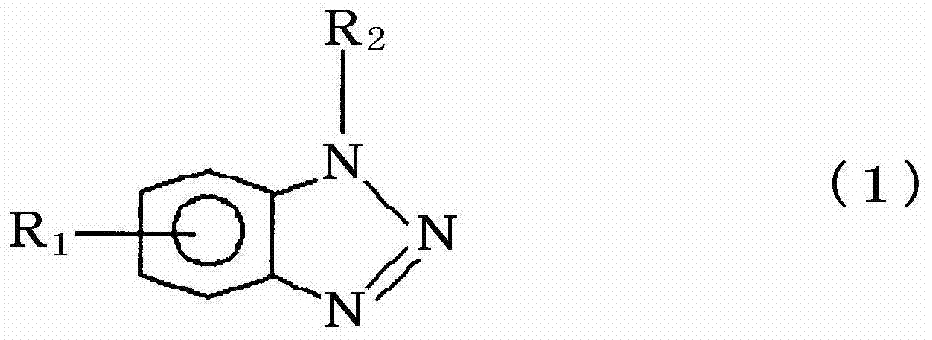

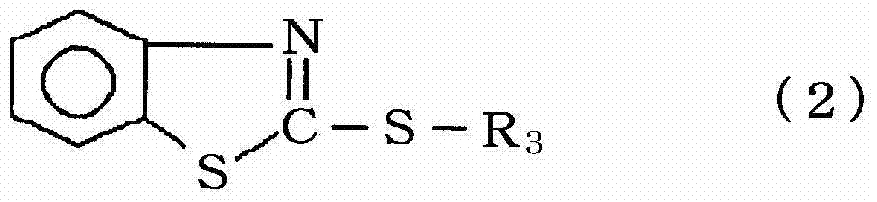

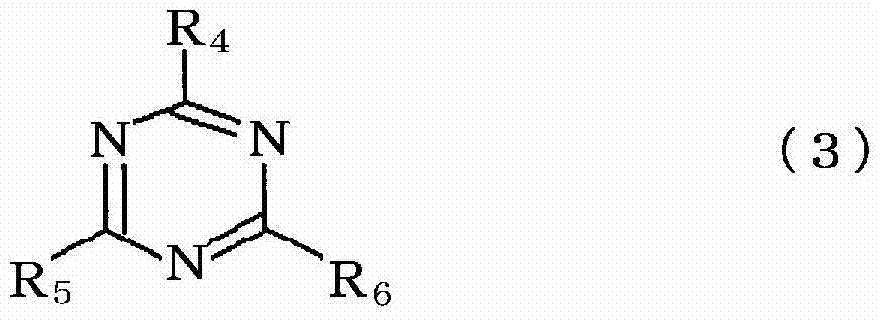

Method used

Image

Examples

Embodiment 1

[0074] As the substrate to be treated, use a pure copper substrate plated with a 4μm thick silver layer, soak it in the surface treatment agent of the following composition at 40°C for 30 seconds, then wash it with water, and dry it with warm air with a blower. for surface treatment.

[0075] Composition of surface treatment agent

[0076]

[0077] Phosphoric acid was used as a pH adjuster to adjust the pH to 5.5.

[0078] For the surface-treated substrate of Example 1, a hydrogen sulfide gas test was performed based on JISH8502 without heat treatment (hydrogen sulfide concentration: 3ppm, temperature: 40°C, humidity: 80%RH, test time: 4 hours) , to observe the appearance with the naked eye. In addition, after heat treatment at 200° C. for 10 minutes with a hot air circulation dryer, heat treatment at 120° C. for 6 hours was performed, and the base material after heat treatment was subjected to the same hydrogen sulfide gas as in the case of no heat treatment. Test and v...

Embodiment 2~8、 comparative example 1~8

[0085] Inhibitor and pH buffering agent in embodiment 1 are changed into compound and concentration recorded in table 1, and the pH value is changed into the value shown in table 1 with phosphoric acid, except that, carry out treated group similarly with embodiment 1 The surface treatment of the material was evaluated in the same manner as in Example 1.

[0086] The results are shown in Table 1.

[0087] [Table 1]

[0088]

[0089] Using the surface-treated substrates of Examples 1, 2, 7, and Comparative Example 1, evaluations of contact resistance, solder wettability, wire bonding properties, and reflectance were performed in the following manner. The results are shown in Table 2.

[0090] (1) Contact resistance

[0091] The contact resistance was measured at a direct current of 7.4 mA, an open voltage of 20 mV, and a load of 2.5 to 50 g. The criteria for judging the contact resistance are as follows.

[0092] ○: Contact resistance is less than 0.02Ω;

[0093] ×: Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com