Centrifugal concrete strength testing test mold and centrifugal concrete strength testing method

A technology of concrete strength and detection method, which is used in the preparation of test samples, and the use of stable tension/pressure to test the strength of materials. and other problems to achieve the effect of saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

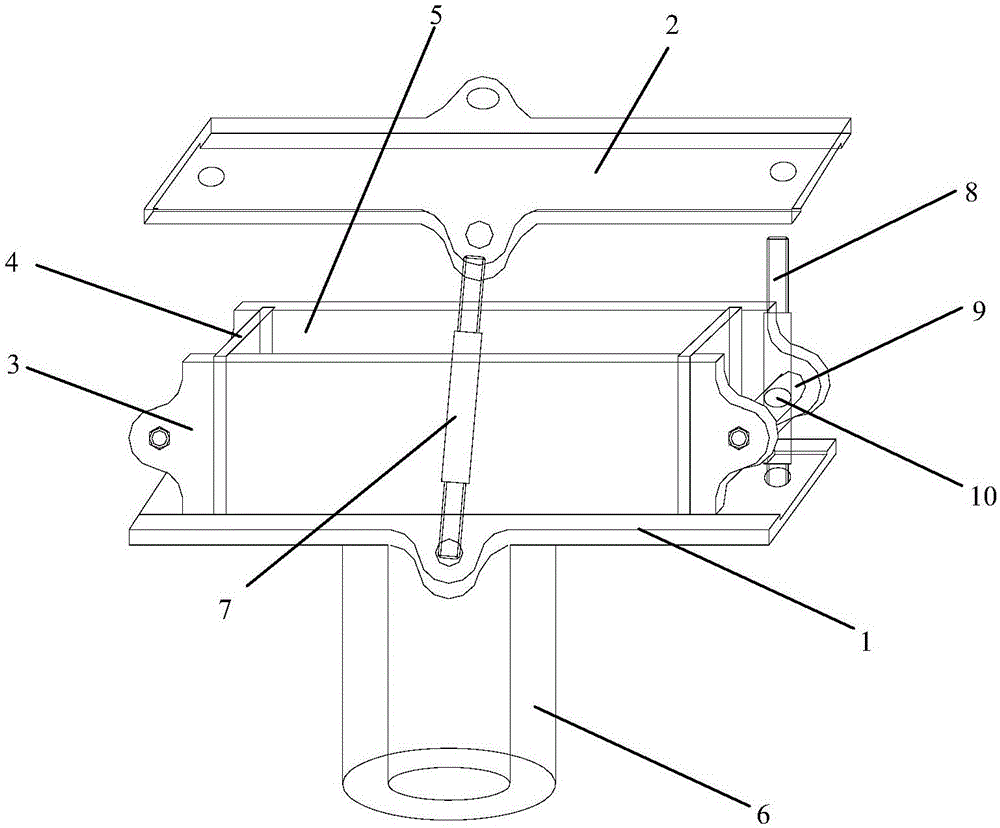

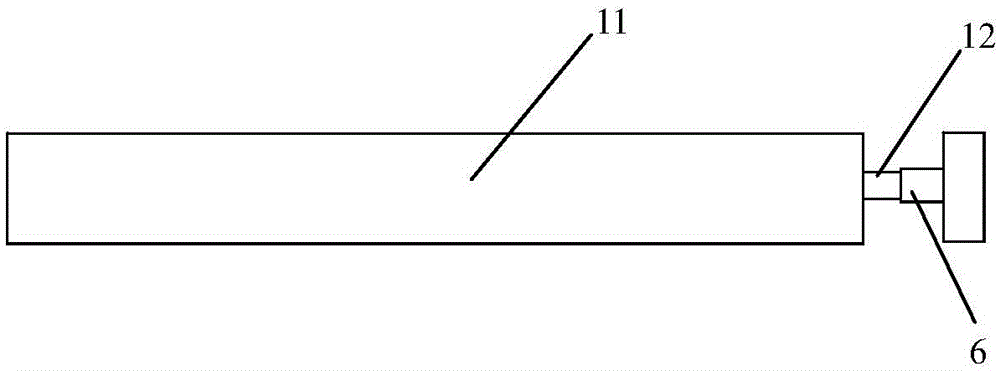

[0012] See figure 1 As shown, the present invention discloses a test model for centrifugal concrete strength testing, which includes a bottom plate 1, a top plate 2, two side plates 3, and two end plates 4 located at both ends of the two side plates 3. The bottom plate 1, the top plate 2, the two side plates 3 and the two end plates 4 together form a cavity 5 for containing concrete. The outer surface of the bottom plate 1 is connected with a tension nut 6. When in use, the tension nut 6 is installed on a tension screw 12 with a mold pipe pile 11 (Such as figure 2 As shown), the axis of the tension nut 6 coincides with the axis of the cavity 5 passing through the top plate 2 and the bottom plate 1.

[0013] In order to position and fix each part, two first upper and lower mold connecting bolts 7 and two second upper and lower mold connecting bolts 8 are connected between the top plate 2 and the bottom plate 1. The two first upper and lower mold connecting bolts 7 They are locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com