Spiral extrusion type solid-liquid separation device for kitchen waste

A technology of screw extrusion and solid-liquid separation, applied in the direction of presses, manufacturing tools, etc., can solve problems affecting urban appearance and living environment, and affecting people's health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

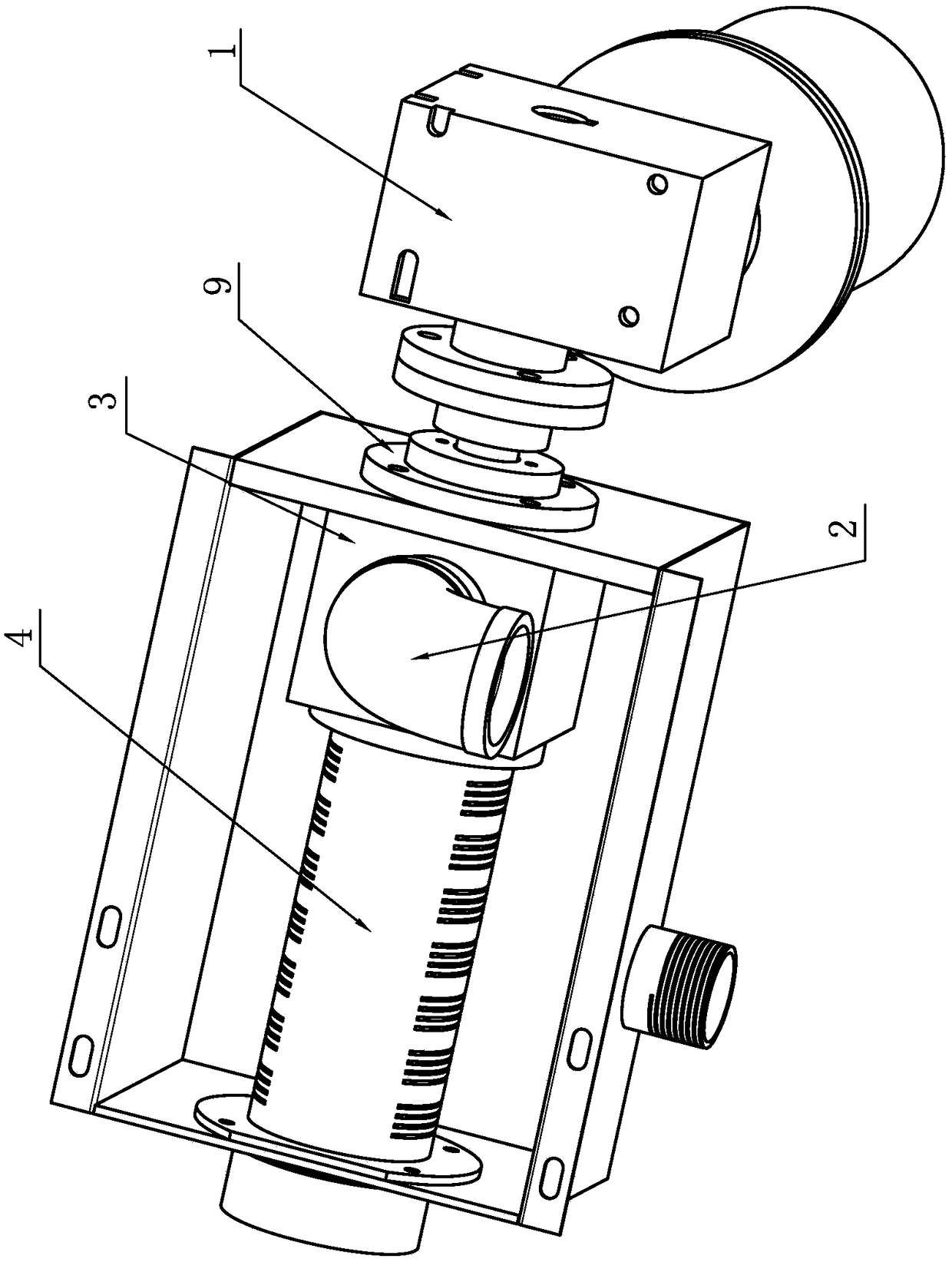

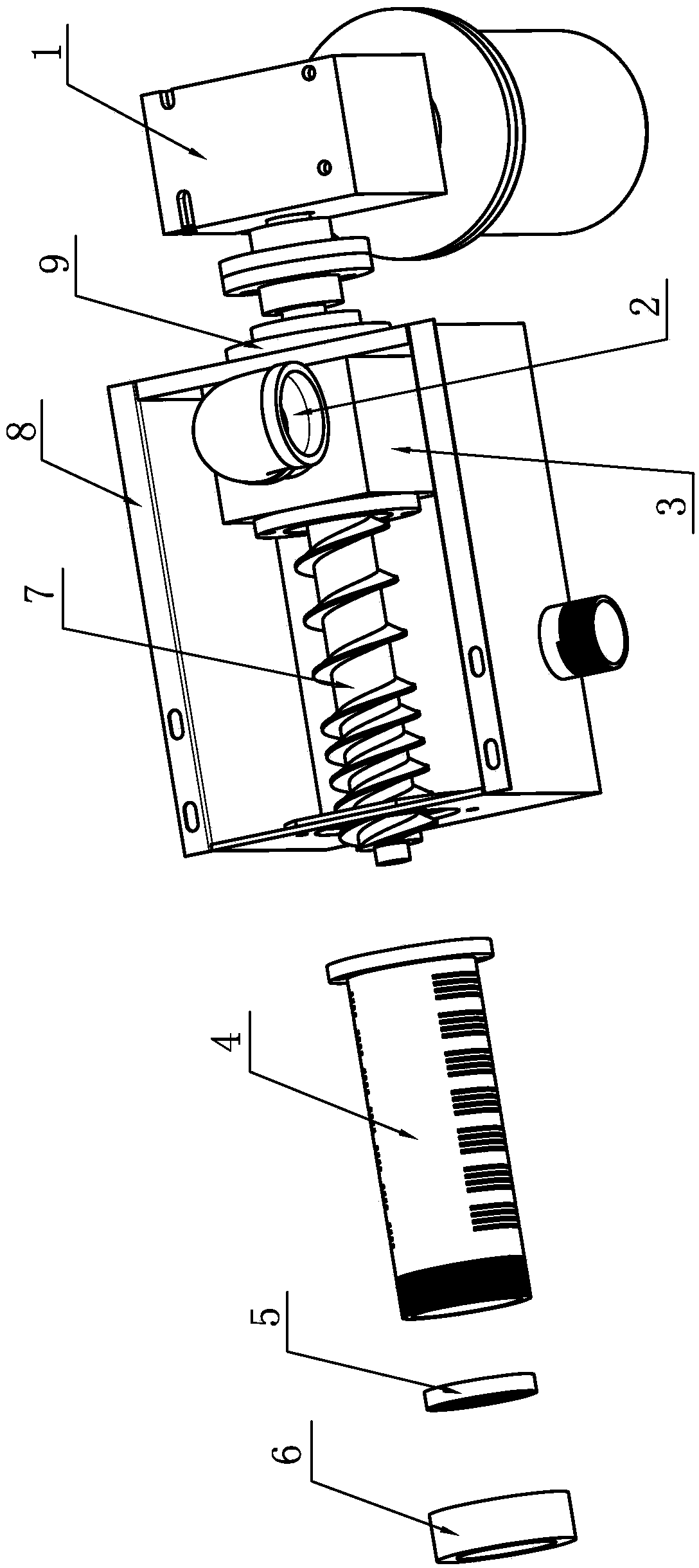

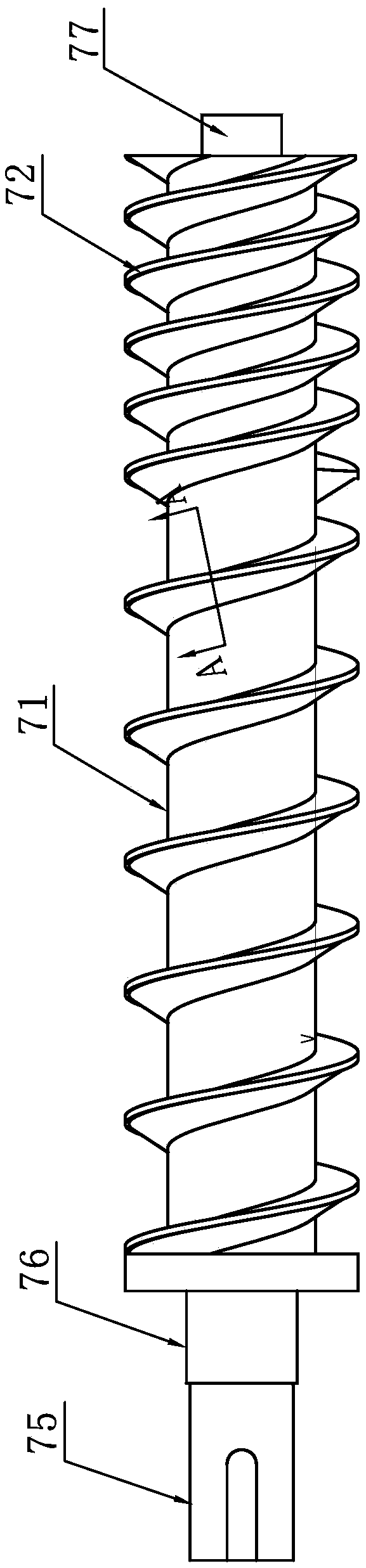

[0029] Embodiment 1: A kind of food waste screw extrusion type solid-liquid separation device, such as Figure 1-Figure 6 As shown, it includes extrusion power part 1, feed pipe 2, feed box 3, extrusion liquid casing 4, end surface discharge plate 5, locking cap 6, extrusion hinge 7, liquid collection box 8 And the bearing seat 9, the feed pipe 2 is arranged on the top plate of the liquid collection tank 8, the extrusion liquid sleeve 4 includes a cylinder 41, a liquid discharge structure 42, a connecting flange 43 and a threaded section 44, and the extrusion liquid sleeve The tube 4 is set on the liquid collection tank 8, the right end of the extruded liquid casing 4 is axially fixed on the right side plate of the liquid collection tank 8 through the connecting flange 43, and the left end of the extruded liquid casing 4 is supported On the left side plate of the liquid collection tank 8, the end surface discharge plate 5 is pressed and fixed on the discharge end surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com