Bistable fluid valve

A fluid valve and bistable technology, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problems of high power consumption of control valves, and achieve the effects of uniform contact pressure, reliable sealing, and uniform sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

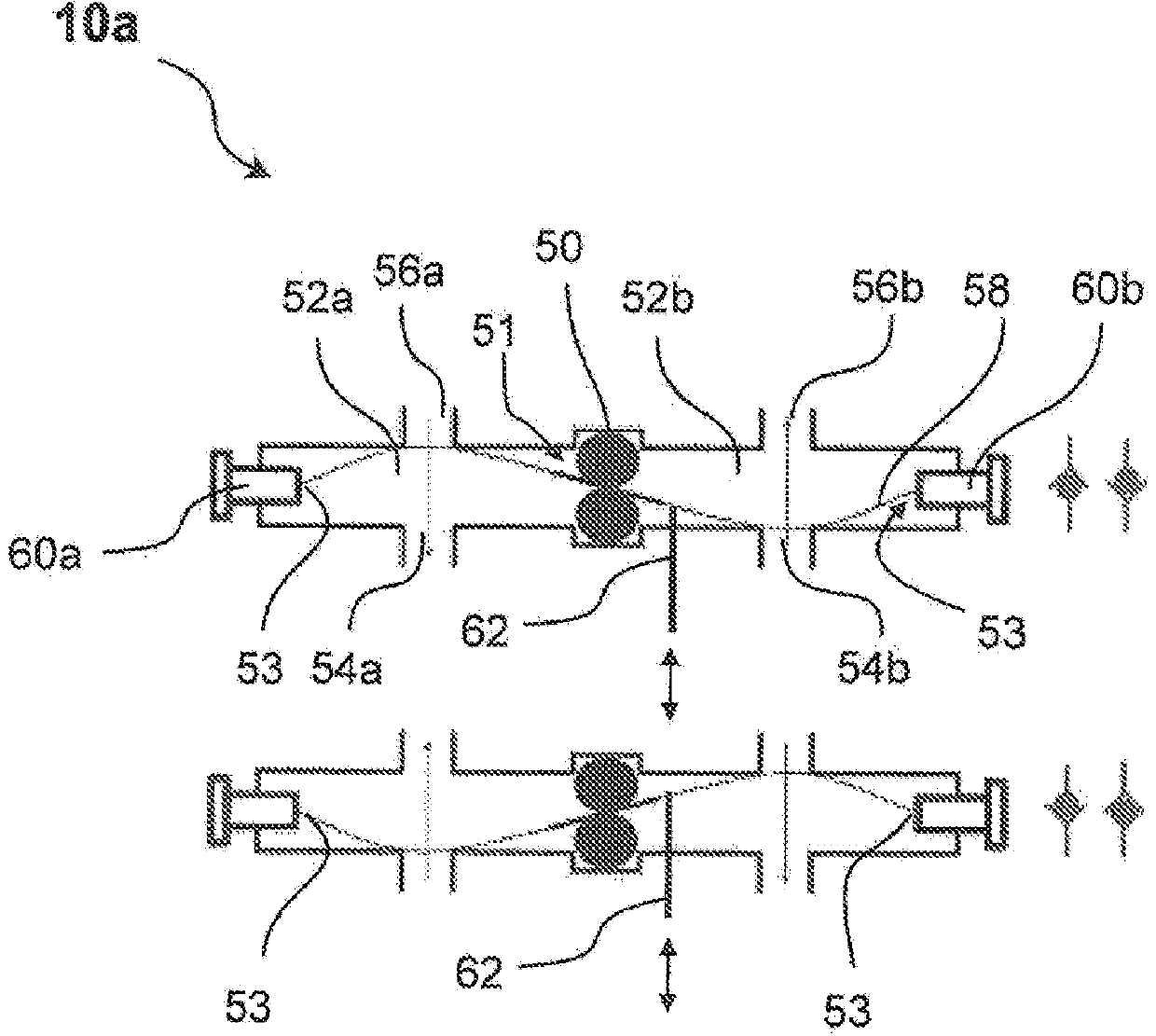

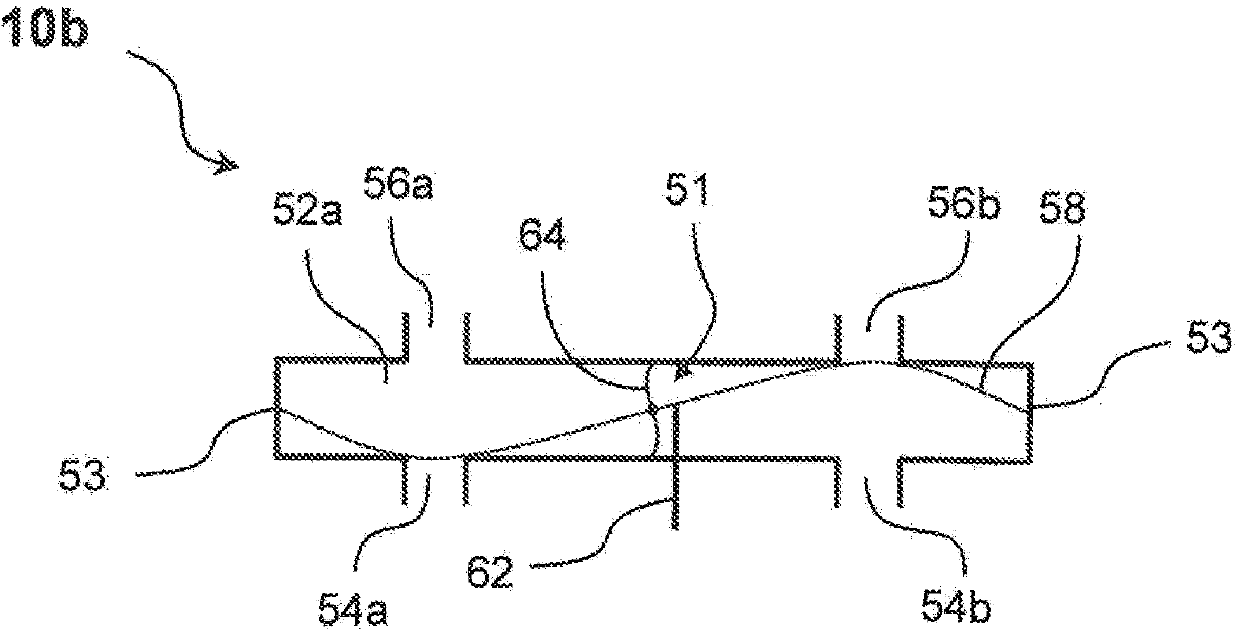

[0025] figure 1 is a schematic view of the fluid valve 10a of the first embodiment in two positions. The fluid valve consists of two valve chambers 52 a , 52 b separated from each other by means of a seal 50 . The two valve chambers 52a, 52b each have an inlet 54a, 54b and an outlet 56a, 56b. The two inlets 54a, 54b preferably communicate with each other in a manner not shown. There is an S-shaped elastic strap element 58 extending inside the two valve chambers 52a, 52b, which strap element 58 is pivotally mounted at the center of the sealing part 50 and is pivotally supported at both ends 53 at Two adjusting screws 60a, 60b. Thus, the sealing portion 50 forms a pivot point 51 for a strap element 58 .

[0026] The strip element 58 has the function of a flap which is positionally variable and presses with a defined pre-pressure onto the valve seat of the outlet 56a, 56b, thereby closing the outlet 56a, 56b. Fluid pressure presses the strap element 58 to the valve seat, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com