Liquid atomization spraying device

A spraying device and liquid atomization technology, applied in the directions of liquid spraying device, spraying device, spraying device, etc., can solve the problems of inability to concentrate rosin spraying, waste of rosin, etc., to improve the atomization effect, prevent the waste of materials, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

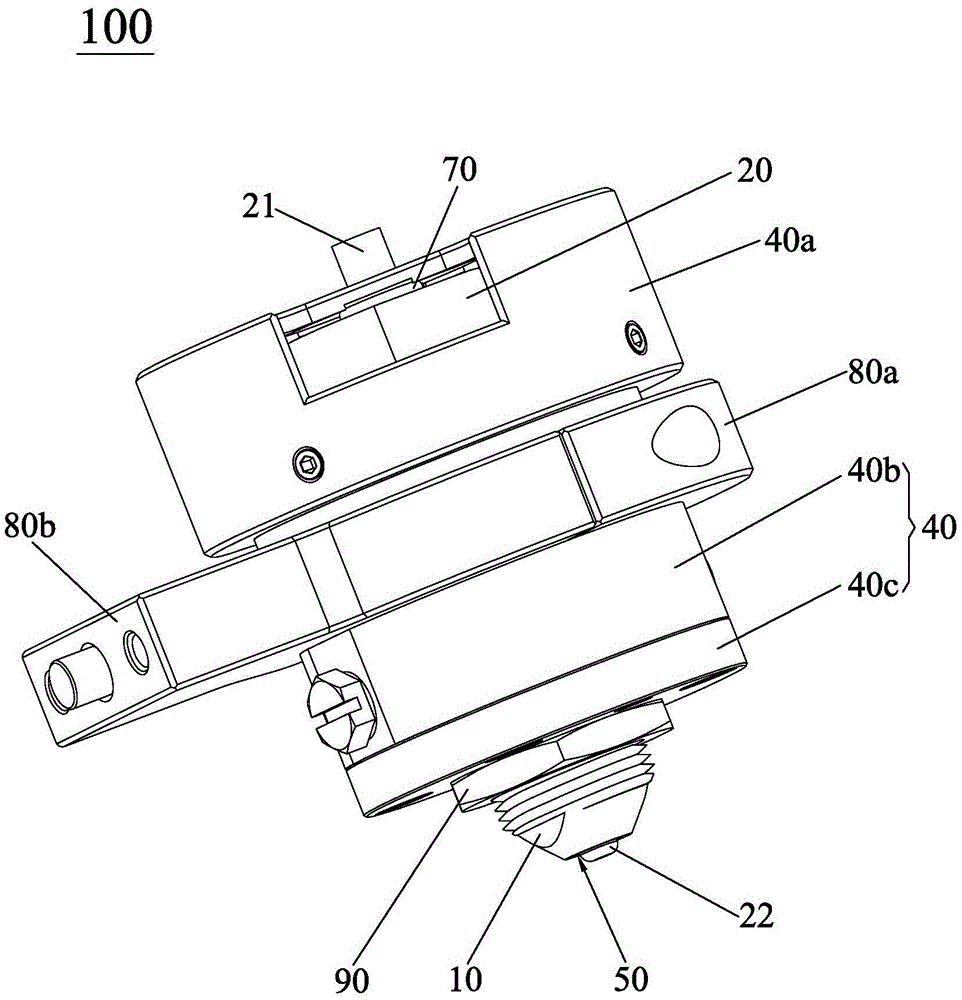

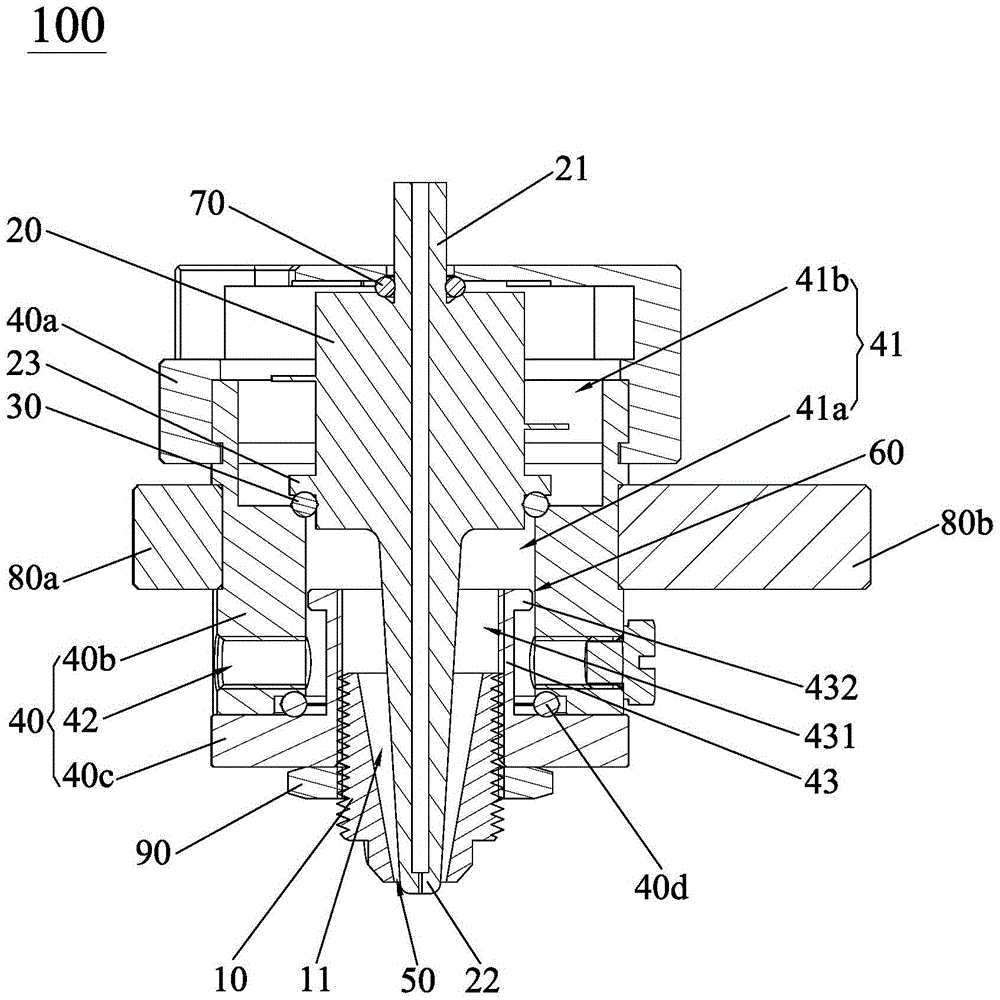

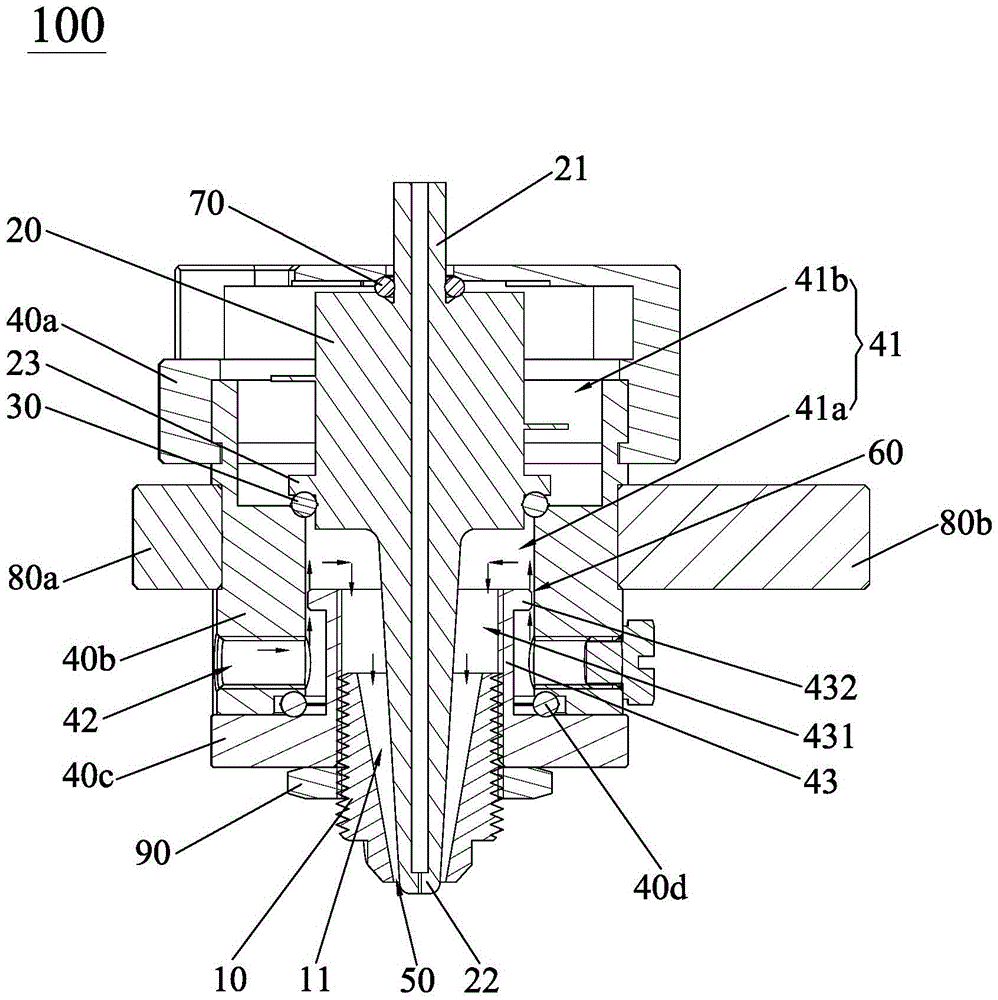

[0023] see figure 1 and figure 2 , the liquid atomizing and spraying device 100 of the present invention is preferably used to atomize the rosin liquid, and spray the atomized rosin on the object, so as to meet the process requirements of spraying rosin in the production process of the magnetic head arm assembly, and this The inventive liquid atomization and spraying device 100 includes a gas injection head 10 , an ultrasonic atomizer 20 , a flexible sealing ring 30 and a hollow cavity 40 . The hollow structure runs through the cavity 40 and forms the storage cavity 41. Specifically, the hollow structure runs through the upper and lower ends of the cavity 40 to facilitate the formation of the storage cavity 41, and the cavity 40 is preferably cylindrical to fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com