A lng air bath vaporizer

A gasifier and gasification tube technology, applied in pressure vessels, container filling methods, fixed-capacity gas storage tanks, etc., can solve the problem of limited frost layer suppression effect, and achieve the effect of suppressing frost formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

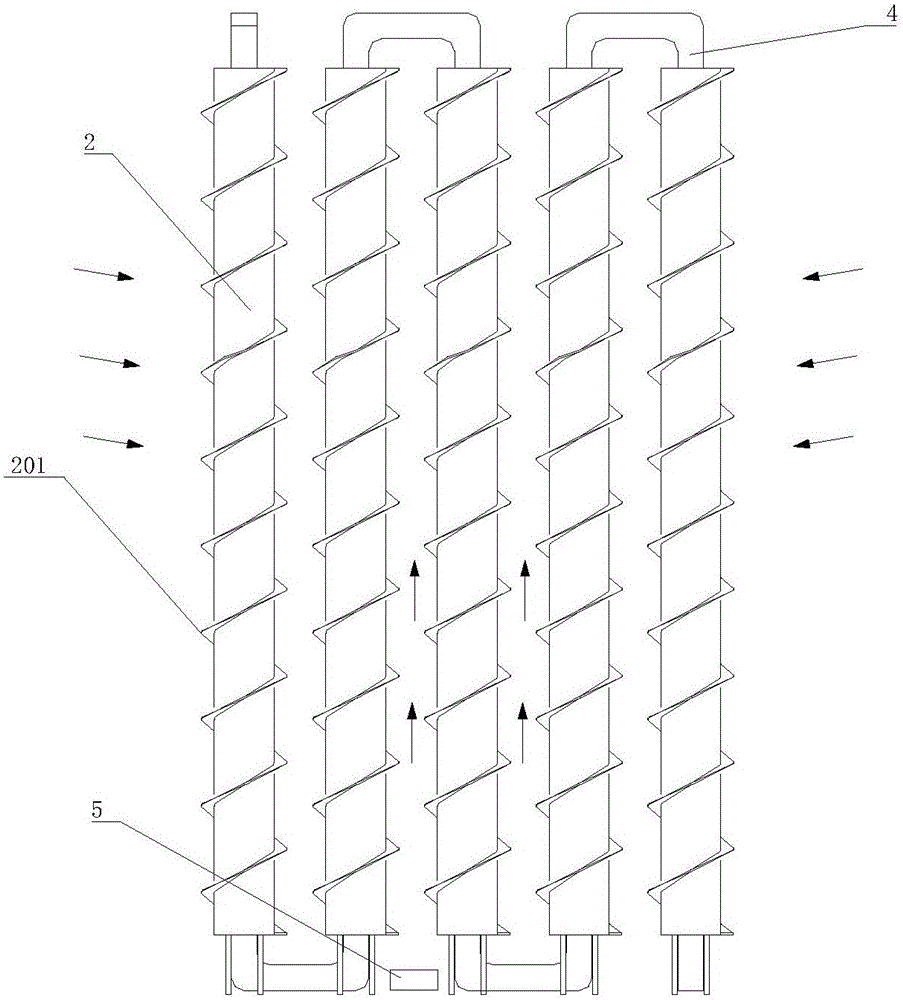

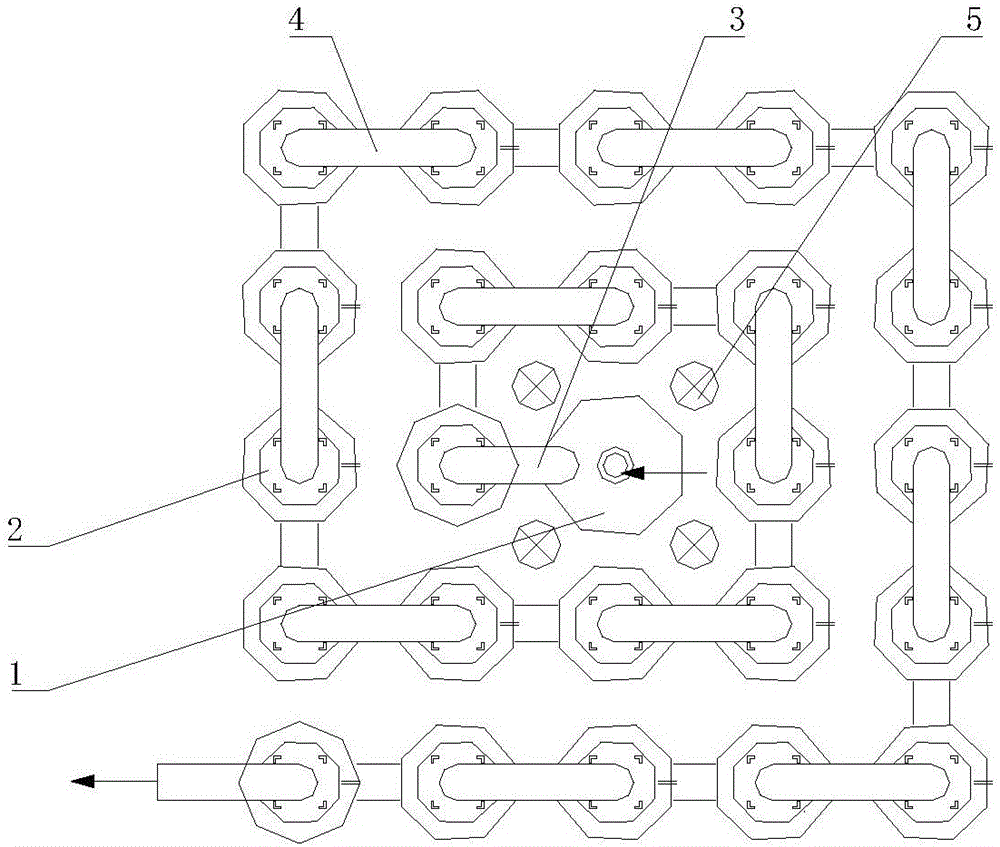

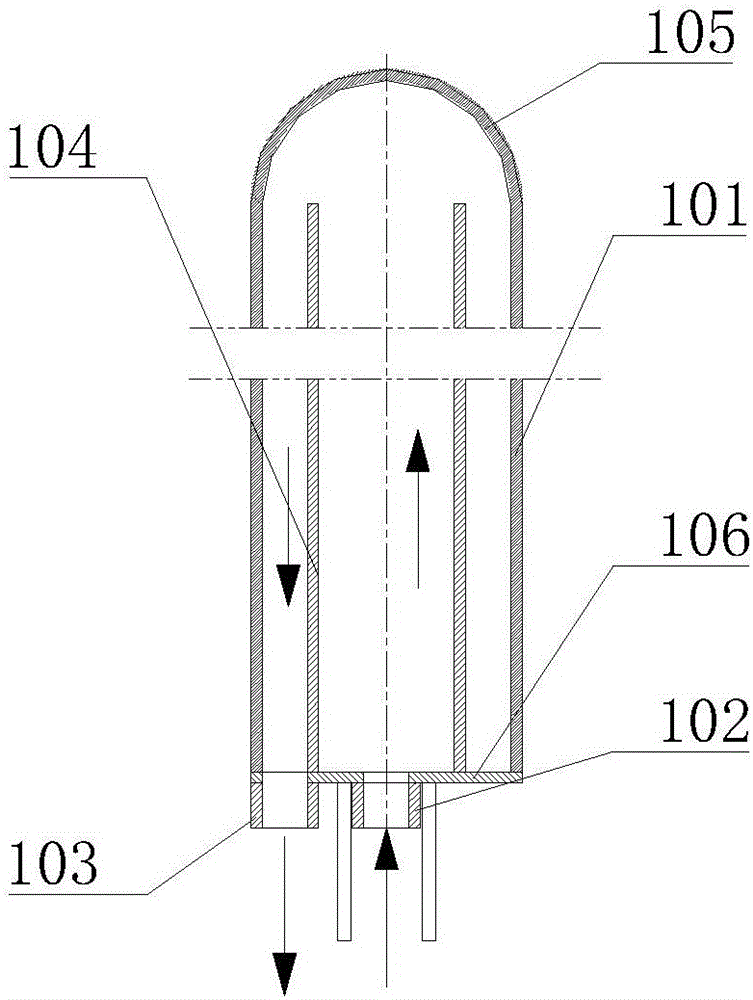

[0019] like Figure 1-3 As shown, a new type of forced draft LNG air-bath vaporizer includes several gasification pipes 2 connected in series through U-shaped connecting pipes 3, and the air inlets of the gasification pipes 2 are connected in series through U-shaped connecting pipes 4 There is an anti-frost pipe connected with the LNG liquid inlet pipe, and the gasification pipe 2 is arranged in parallel with the anti-frost pipe body. The anti-frost tube includes an outer tube 101 and an inner tube 104 that are sheathed together. One end of the inner tube 104 is provided with an LNG liquid inlet and a liquid inlet pipe joint 102, and the end of the outer pipe 101 away from the liquid inlet is provided with a hemispherical tube A sealing plate 106 is provided at one end of the liquid inlet between the cap 105 , the outer tube 101 and the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com