Absorption frost prevention system for refrigeration house and absorption frost prevention method

A technology of cold storage and adsorption bed, which is applied to the adsorption anti-frost system for cold storage and the field of adsorption anti-frost, which can solve the problems of evaporator frosting, high energy consumption of cold storage, and additional consumption of fossil fuels, so as to avoid defrosting operation and cold storage Good performance, anti-frosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation

[0021] Below in conjunction with the accompanying drawings, the embodiments of the present invention are described in detail: the present embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation modes and specific operation processes, but the protection scope of the present invention is not limited to the following example.

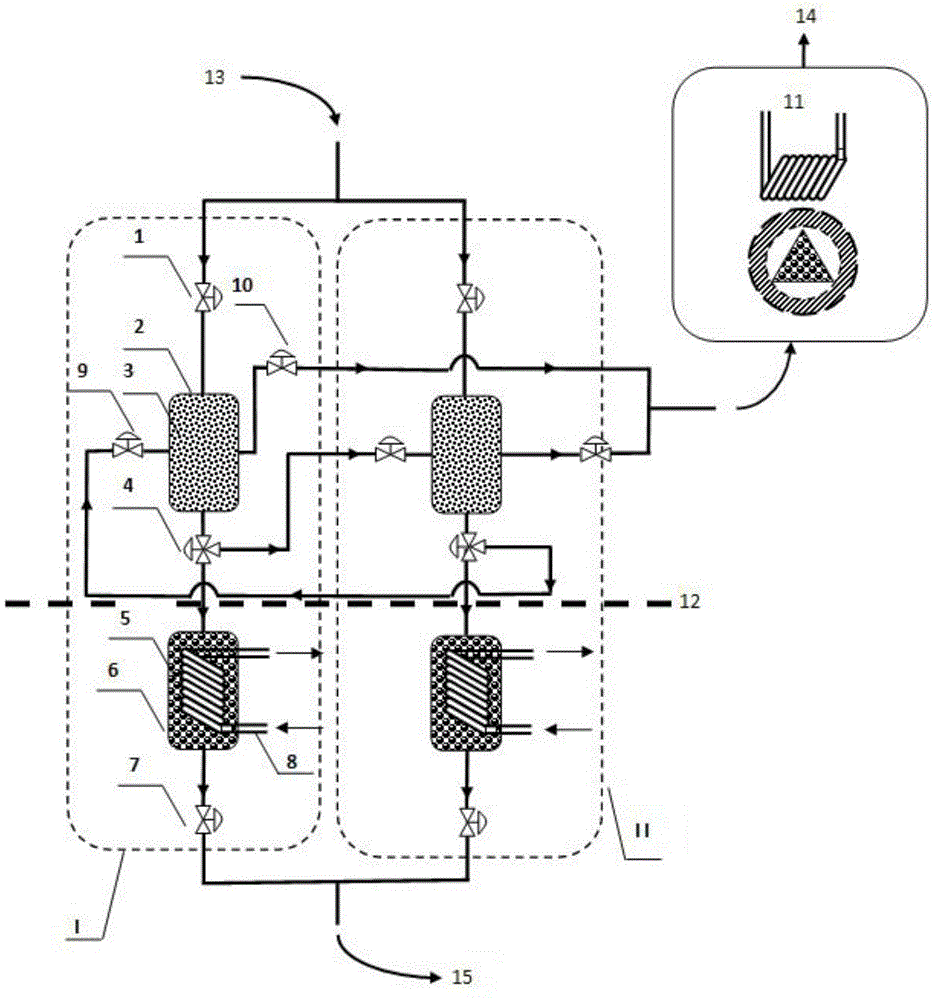

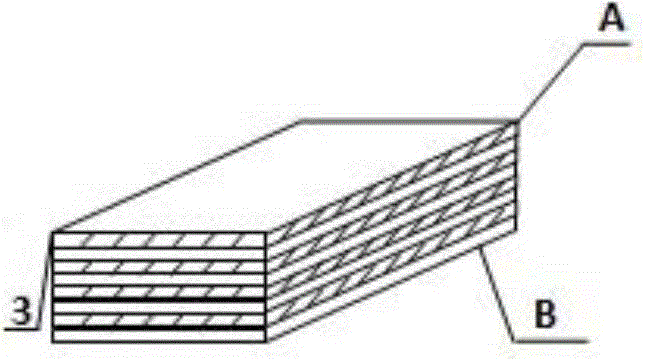

[0022] like Figure 1-Figure 2 As shown, in this embodiment, it is composed of unit I and unit II with the same structure. Unit I includes an inlet valve 1, a low-temperature adsorption bed 2, a desorption back-cooling valve 4, a high-temperature adsorption bed 6, an exhaust valve 7, and a back-cooling valve. Valve 9, return valve 10; low temperature adsorption bed 2 includes adsorbent channel layer A and cooling channel layer B alternately arranged in sequence, and adsorbent channel layer A is filled with low temperature adsorbent 3; high temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com