Dust collection device and method for detecting fire in dust collection device

A technology of a dust collecting device and a detection method, which is applied in the direction of electric fire alarm, fire rescue, separation method, etc., can solve the problems of not being an effective method, time-consuming maintenance of smoke sensors, and inability to completely make up for defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

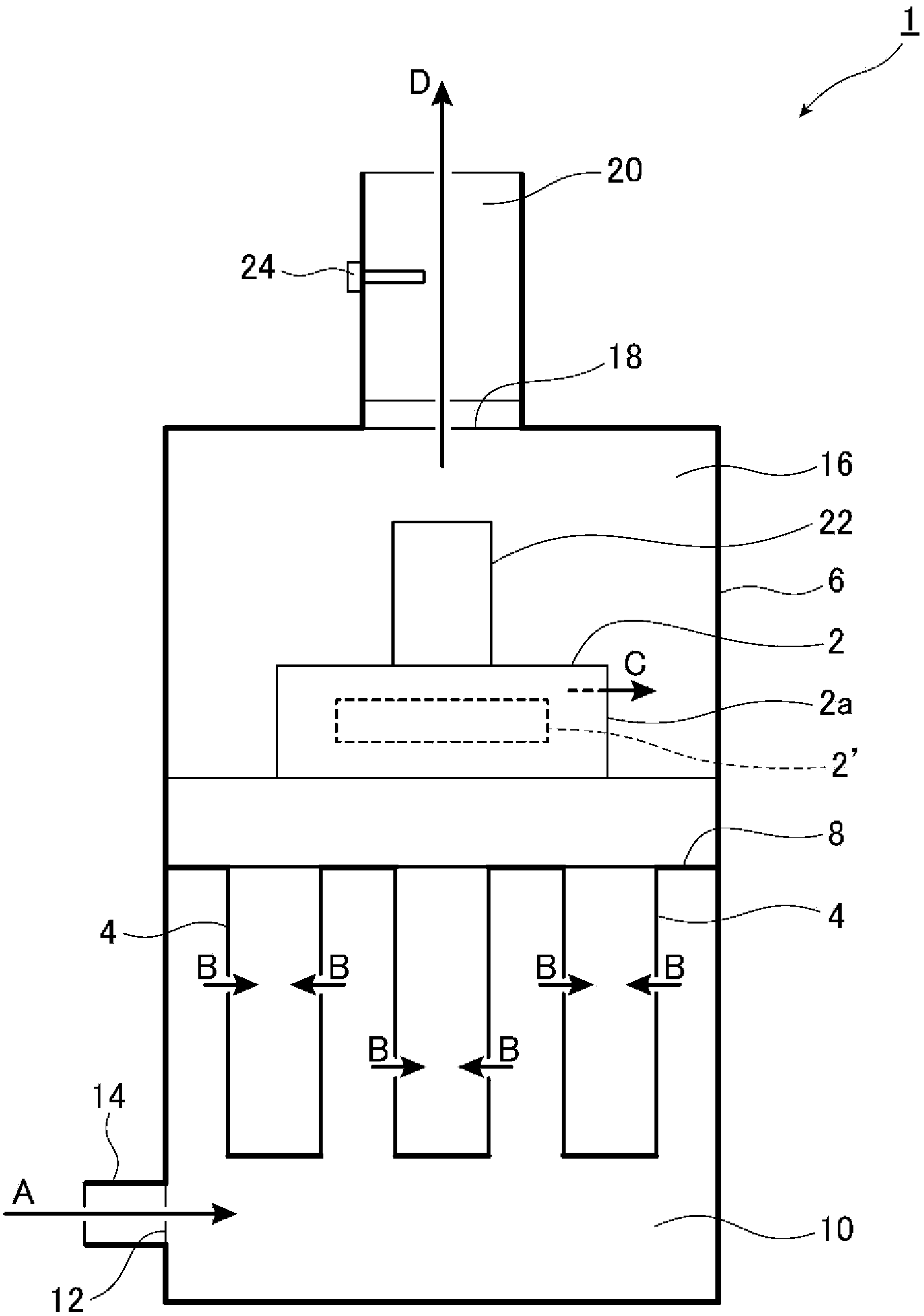

[0081] Next, a fire experiment performed as an example of the present invention will be described.

[0082] Figure 8 is the dust collecting device 50 used in the experiment and figure 1 Same attached picture. For the dust collector 50, its basic structure is the same as that of the dust collector 40 of the second embodiment. The difference between the dust collector 50 and the dust collector 40 is that the dust detection sensor is installed on the downstream side before the blower outlet 2a. On the basis of 42, temperature sensors 52, 54 are respectively installed at the inlet of the blower and the outlet of the blower 2a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com