Cable arrangement structure of multi-joint robot

A multi-joint robot and robot technology, applied in the direction of robots, manipulators, mechanical equipment, etc., can solve the problems of large-scale abutment and troublesome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

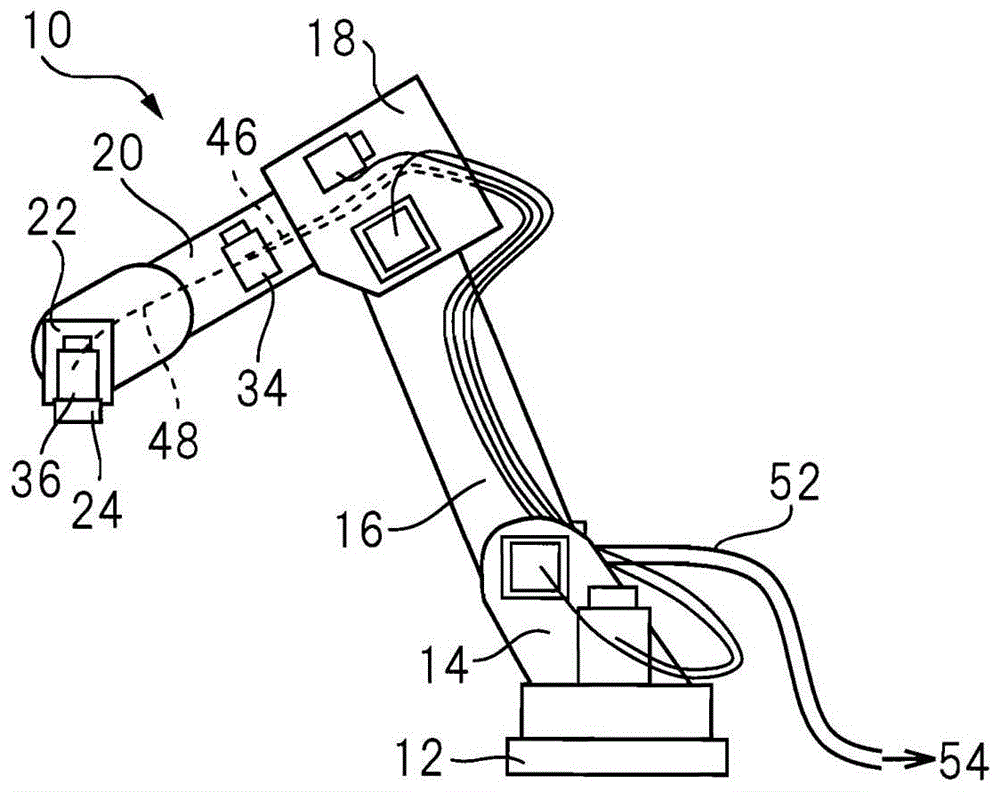

[0034] figure 1 It is a figure which shows the schematic structure of the articulated robot provided with the cable handling structure of 1st Embodiment of this invention. The articulated robot 10 includes: a base 12; a revolving body 14 rotatably connected to the base; a first arm 16 rotatably connected to the revolving body 14; 16 is a second arm 18 connected in a rotatable manner. In addition, in this embodiment, the robot 10 is illustrated as a six-axis multi-joint robot. Specifically, the robot 10 may further include: a first wrist element 20 connected to the second arm 18 in a rotatable manner; The second wrist element 22 rotatably connected to the first wrist element 20 , and the third wrist element 24 rotatably connected to the second wrist element 22 .

[0035] The motors that drive the respective axes of the robot 10 are respectively installed on the components driven by the respective motors or in the vicinity thereof. In the illustrated example, the first to si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com