Rotary compact spinning fiber gathering device

A rotary, fiber bundling technology, applied in the field of fiber agglomeration device and spinning processing equipment, can solve the problems of decreased evenness evenness and insufficient agglomeration of fiber bundles, and achieves high evenness and low frictional resistance. , the effect of less hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

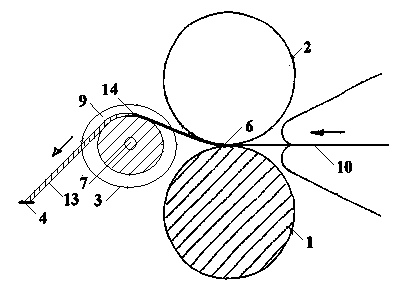

[0021] Such as image 3 , 4, in this embodiment, the rotary compact spinning fiber gathering device consists of a drafting roller 1, a drafting top roller 2, a fiber bundler 3, a yarn guide hook 4 and a support mechanism 8 fixedly installed The connecting shaft 5 is composed. The drafting roller 1 is tightly pressed on the drafting top roller 2 to form a drafting nip line 6 . The fiber bundler 3 is arranged downstream of the drafting nip line 6, so that the fiber bundler 3 forms a positive grid distance with the drafting roller 1 and the drafting top roller 2 respectively. The yarn guide hook 4 is arranged downstream of the fiber bundler 3 . A shaft hole 7 is opened on the fiber bundler 3, and one end of the connecting shaft 5 is installed in the shaft hole 7 through a rolling bearing, and the other end of the connecting shaft 5 is fixedly installed on the support mechanism 8, so that the fiber bundler 3 can Driven to rotate around the connecting shaft 5. There is an annul...

Embodiment 2

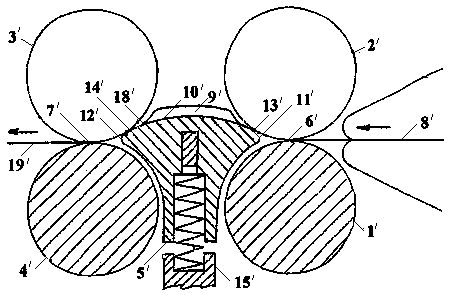

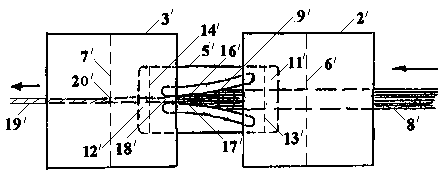

[0023] Such as Figure 5 , 6 As shown, in this embodiment, the rotary compact spinning fiber gathering device consists of a drafting roller 1, a drafting top roller 2, a fiber cluster 3, a yarn guide hook 4 and a connecting shaft fixedly installed on a supporting mechanism 8. 5 composition. The drafting roller 1 is tightly pressed on the drafting top roller 2 to form a drafting nip line 6 . The fiber bundler 3 is arranged downstream of the drafting jaw line 6 , and the yarn guide hook 4 is arranged downstream of the fiber bundler 3 . A shaft hole 7 is opened on the fiber bundler 3, one end of the connecting shaft 5 is installed in the shaft hole 7 through a rolling bearing, and the other end of the connecting shaft 5 is fixedly installed on the support mechanism 8, so that the fiber bundler 3 can be driven by an external force. Rotate around connecting axis 5. Different from Embodiment 1, in this embodiment, the drafting top roller 2 is tightly pressed on the fiber bundler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com