Apparatus for setting weft insertion condition in an air jet loom

A technology of weft yarn and condition, which is applied in the equipment field of weft yarn insertion condition, and can solve problems such as uncovered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

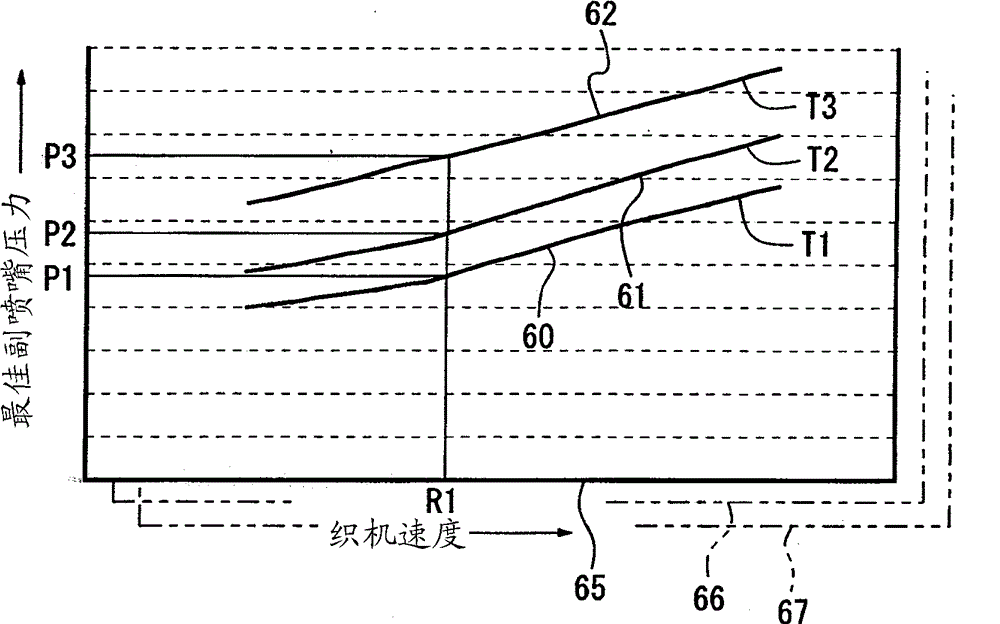

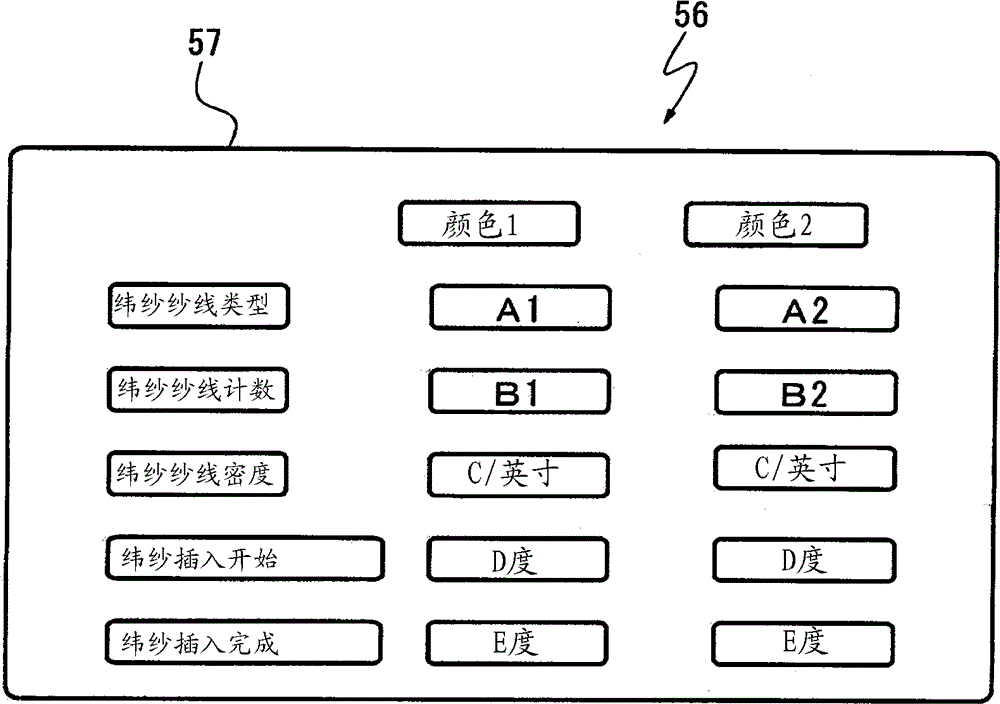

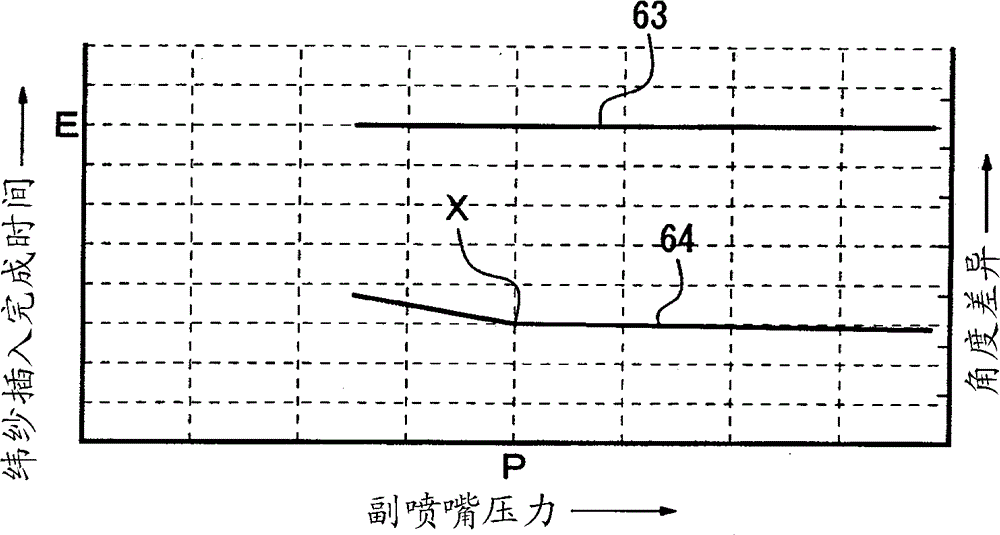

[0015] See below Figure 1-6 One embodiment of an apparatus for setting weft yarn insertion conditions in an air jet loom according to the present invention will be described. It should be noted that the terms "upstream" and "downstream" appearing in the following description are used to indicate the direction or relative position with respect to the direction along which the weft yarn is inserted into the warp shed, And compressed air supplied from an external source flows in the one direction.

[0016] see figure 1 , the air jet loom marked by 1 includes a weft insertion (weft insertion) device 2 , a plurality of sub-nozzles 3 and an end nozzle 4 arranged downstream of the weft insertion device 2 along a reed 59 having a plurality of reed teeth 58 . In the figure, the compressed air supply lines leading to the weft thread insertion device 2, the secondary nozzle 3 and the end nozzle 4 are also shown in the form of a block diagram. The weft thread insertion device 2 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com