Sensor

A technology for sensors and outer shells, applied in the field of sensors, which can solve the problems of transferring chemical characteristics to sensors, low precision, and slow response of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

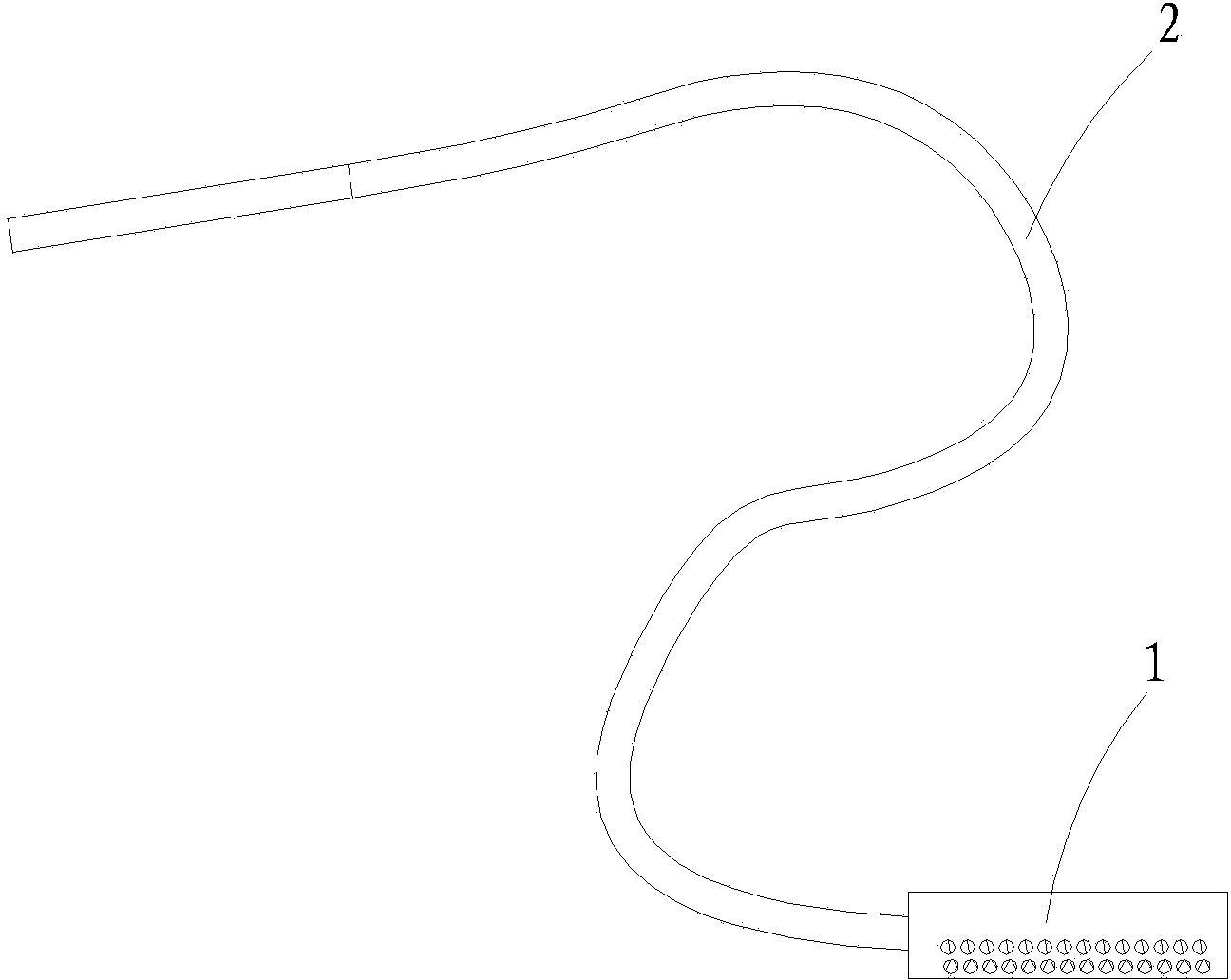

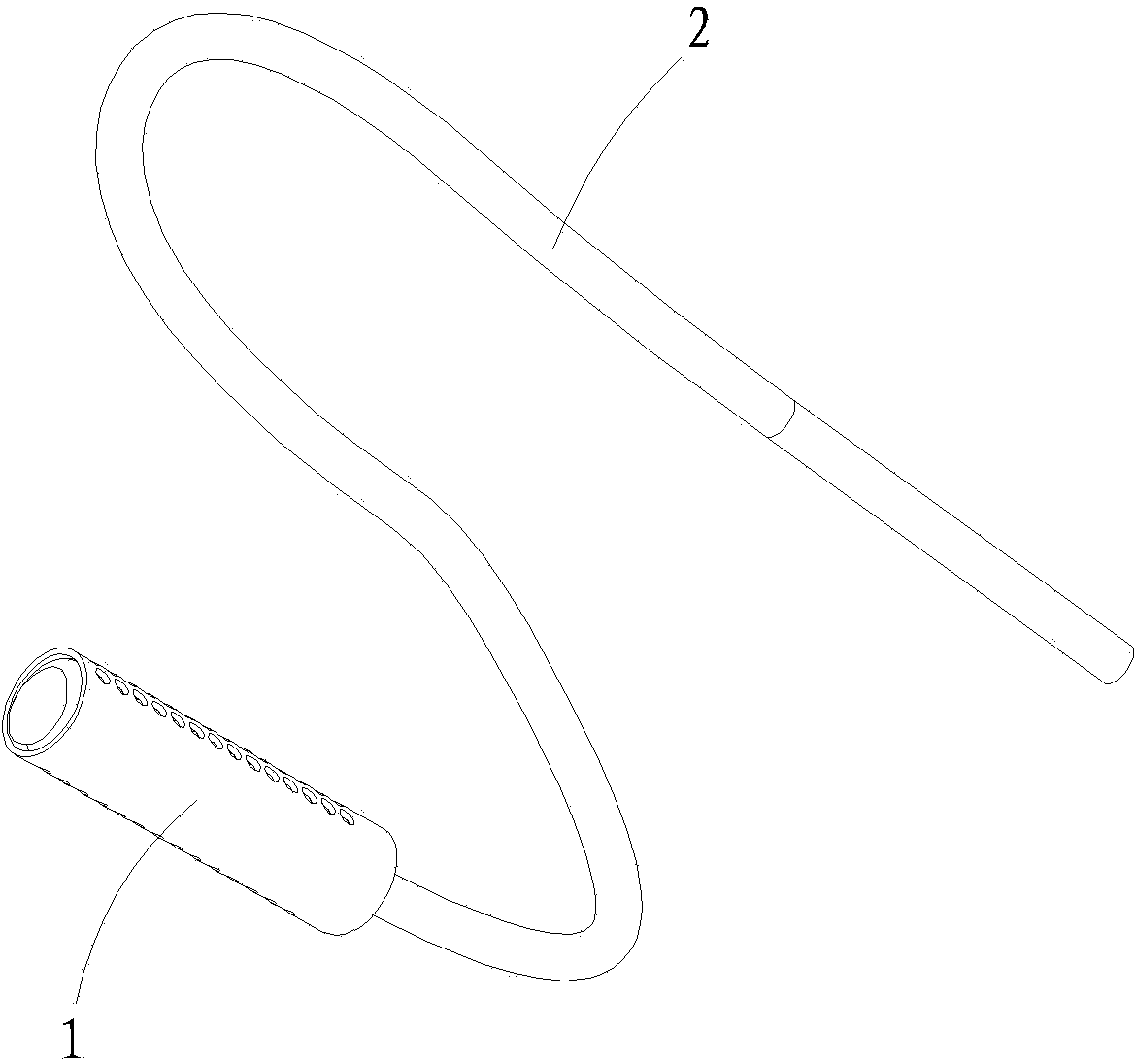

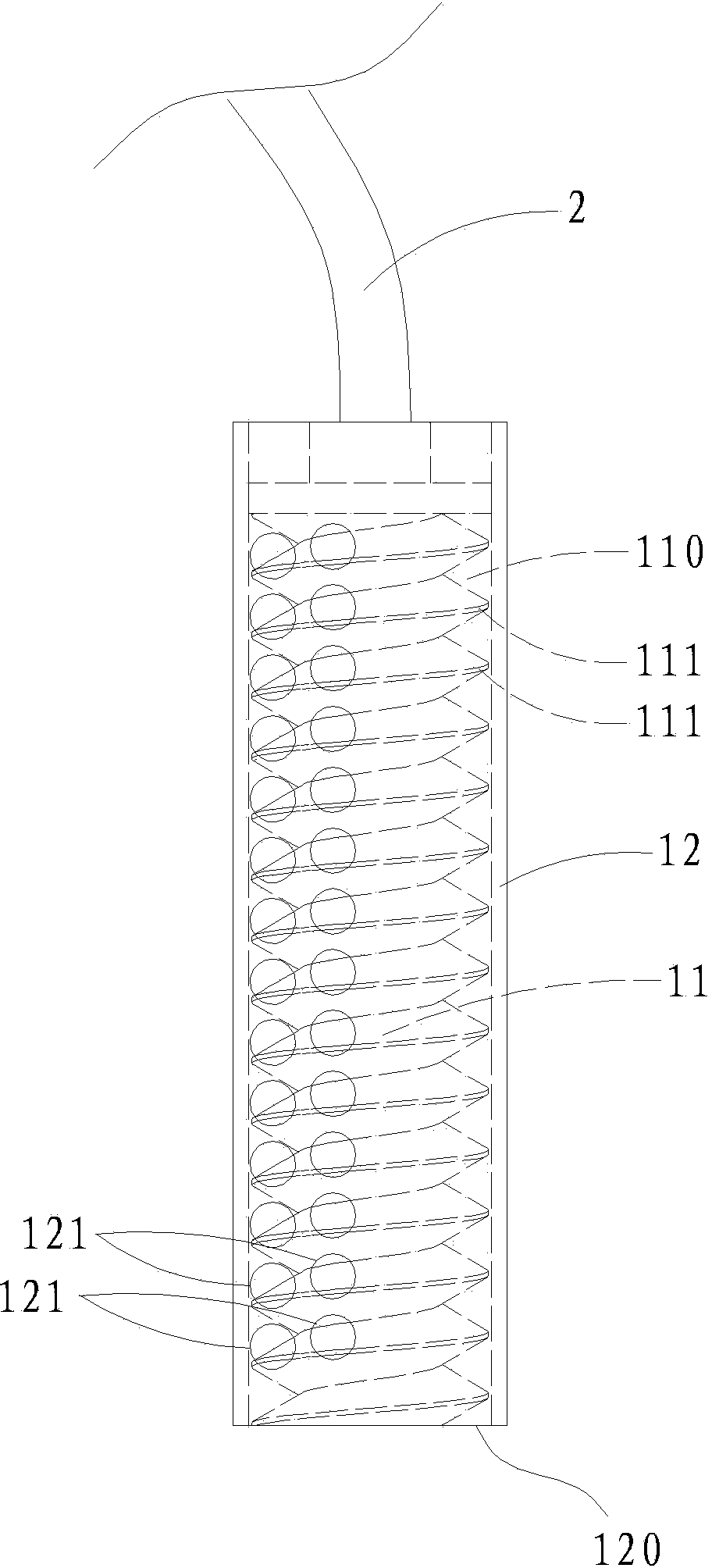

[0025] See Figure 1a , Figure 1b with figure 2 , image 3 As shown, the sensor of this embodiment includes a probe 1 for measurement and a cable 2 connected to the upper end of the probe 1. The probe 1 of the sensor includes an inner part 11 and an outer body 12 sleeved with the inner body 11, the inner part 11 is provided with a core of the sensor (not shown in the figure), and the surface of the inner part 11 has A section of spiral channel 110, the lower end of the outer shell 12 has an opening 120, so that the inner part 11 and the outer shell 12 sleeved with the inner body 11 form a hollow double-layer structure with a spiral channel and an open lower end; and The outer shell 12 is provided with a plurality of through holes 121 at positions corresponding to the inner spiral channel. Among them, in this embodiment, the multiple through holes 121 opened on the outer shell 12 are distributed on two straight lines (for ease of processing), and the distance between the holes ...

Embodiment 2

[0030] See Figure 4 with Figure 5 As shown, the second embodiment is basically the same as the first embodiment, the difference is: the through hole 121 opened on the outer shell 12 in the second embodiment is a square hole, while the outer shell 12 in the first embodiment is opened The through hole 121 is a round hole. Of course, the through holes 121 opened on the outer shell 12 in other embodiments may also be elliptical holes or through holes of other shapes.

[0031] In addition, the multiple through holes 121 formed on the outer shell 12 in the second embodiment can also be roughly distributed in a straight line, and for other changes, please refer to the above description of the first embodiment.

Embodiment 3

[0033] See Image 6 As shown, this embodiment 3 is different from the above-mentioned embodiment 1 and embodiment 2 in the way of opening a plurality of through holes 121 on the outer shell 12, instead of the elongated slot 122, and the rest is the same. By replacing the above-mentioned design of multiple through holes 121 arranged on one or more straight lines with elongated slots 122 on the outer shell 12, similar effects can basically be achieved, but the processing and manufacturing are more Convenient.

[0034] In order to explain in more detail that the sensor of the present invention does have technical advantages compared to the prior art, the following further expands the description with the measurement application method of Embodiment 1.

[0035] See Figure 7 with Picture 8 As shown, embodiment 1 is installed and placed in a pipe 3 for measurement. When the probe 1 of Embodiment 1 is installed and placed, the outer shell 12 of the probe 1 is provided with a through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com