variable capacitor generator

A technology of variable capacitors and generators, applied in the direction of induction generators, etc., can solve the problems of small power/weight ratio, low conversion efficiency, and large consumption, and achieve high power/weight ratio, less use, and low calorific value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

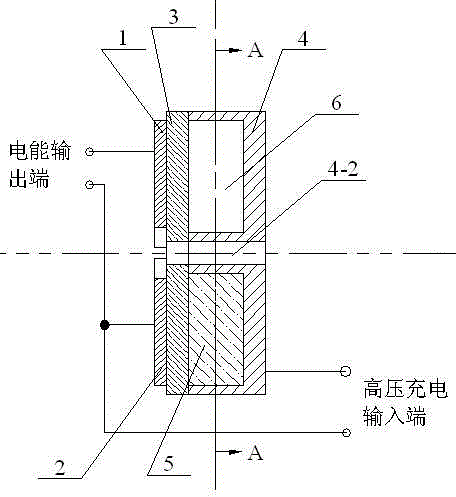

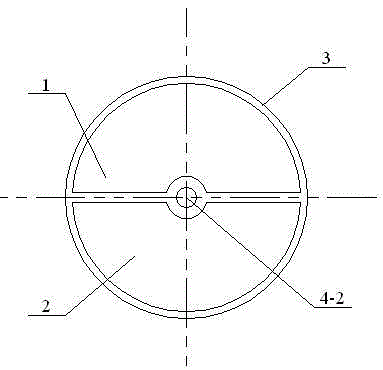

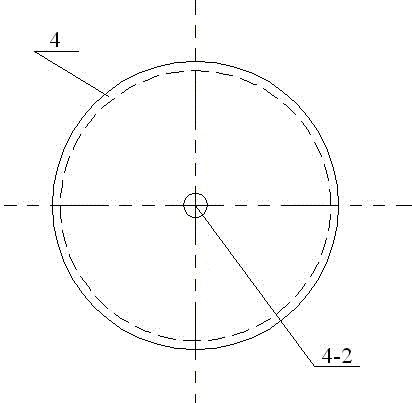

[0008] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 Describe this embodiment, this embodiment consists of a first semicircular conductive metal sheet 1, a second semicircular conductive metal sheet 2, a dielectric disc 3, a circular iron tank 4, a conductive liquid 5, and an inert gas 6;

[0009] An end face of the first semicircle conductive metal sheet 1 and an end face of the second semicircle conductive metal sheet 2 are all connected with an end face of the dielectric disc 3, and the first semicircle conductive metal sheet 1 is opposite to the second semicircle conductive metal sheet 2 to form a The circular iron grooves are insulated from each other; the circular iron grooves 4 are sheet-shaped cylinders with a rotating shaft hole 4-2, and an annular groove 4-1 is opened on the left end surface of the circular iron grooves 4; The other end surface of the dielectric disc 3 is sealed and connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com