Self-propelled peanut combine harvester and peanut harvesting method

A combine harvester and self-propelled technology, which is applied to digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of polluted environment, limited soil conditions, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

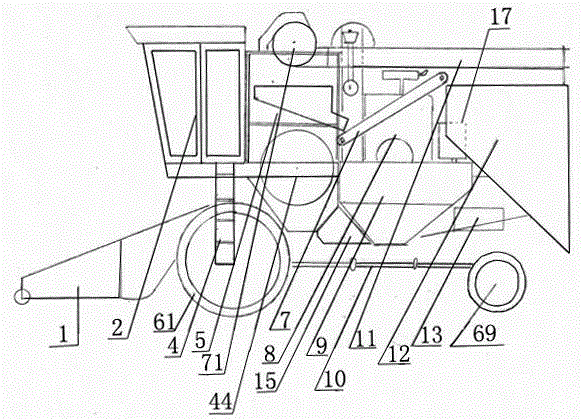

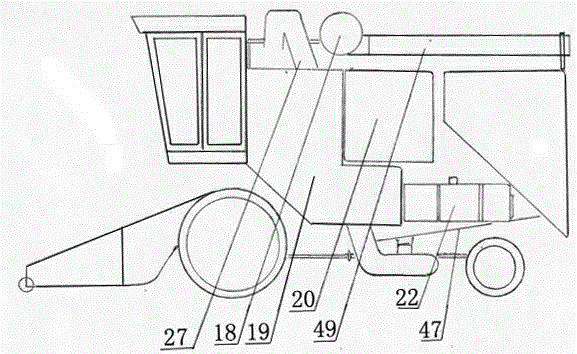

[0035] A self-propelled peanut combine harvester, comprising a peanut seedling removal mechanism 1, a peanut fruit picking mechanism, a peanut fruit lifting mechanism 27 and a peanut selection mechanism 5;

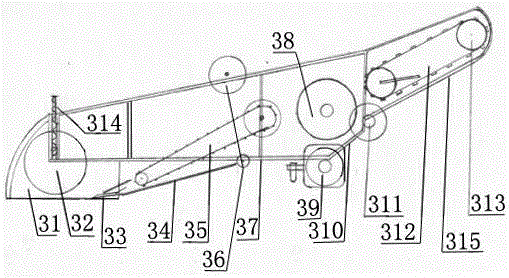

[0036] The peanut seedling removal mechanism includes a front ridge divider 31, a depth adjustment roller 32, a vibrating blade assembly 33, a blade connecting rod 34, a seedling lifting chain 35, a vibrator power shaft 36, a front main frame 37, a converging Auger 38, pendulum ring box 39, swing screen bottom 310, front drive shaft 311, bridge chain climbing 312, bridge intermediate shaft 313, depth adjustment screw 314 and bridge 315, and front ridge divider 31 is set at the front At the forefront of the main frame 37, the depth adjustment cylinder 32 is arranged behind the front splitter, and the vibration blade combination 33 is arranged behind the dept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com