Adjustable safflower filament picking device

An adjustable and safflower technology, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problem of changing picking posture, inability to pick different heights of curd filaments at one time, and inability to adapt to harvesting of safflower filaments of different heights and other problems to achieve the effect of improving the recovery rate and solving the problem of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

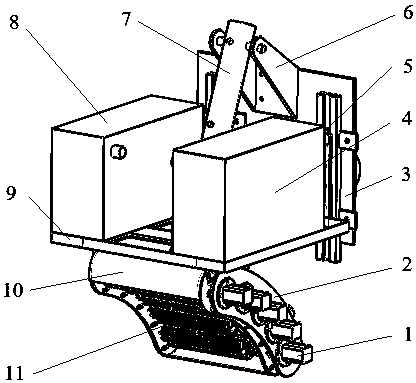

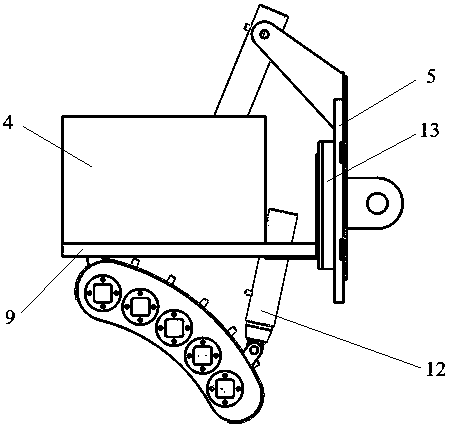

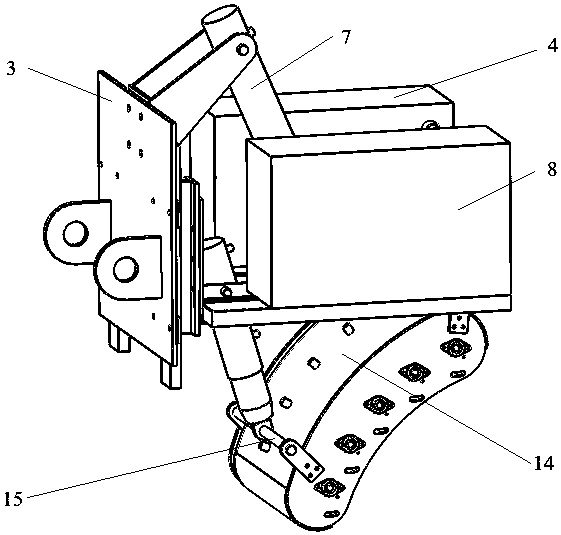

[0016] see figure 1 , an adjustable safflower filament harvesting device. During the forward movement of the whole machine, the curd enters the picking head 11, and the picking head 11 completes the picking of the filaments. The picked filaments, under the action of negative pressure, pass through the curved rear end cover 14 and are collected to the right side. Side collection box 4 and left collection box 8. Through the action of the lifting hydraulic cylinder 7, the up and down movement of the lifting platform 9 is realized, thereby meeting the requirements of working and non-working states. By adjusting the attitude of the hydraulic cylinder 12, the angle between the curved surface and the lifting platform 9 can be changed, and the effective picking length of the picking surface in the horizontal and vertical directions can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com