Built-in no-side-gap gear angle adjusting device of inclined roller straightening machine

An angle adjustment device and straightening machine technology, which is applied in the field of straightening roller angle adjustment devices, can solve problems such as inconvenience, and achieve the effects of cost reduction, accurate transmission chain, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

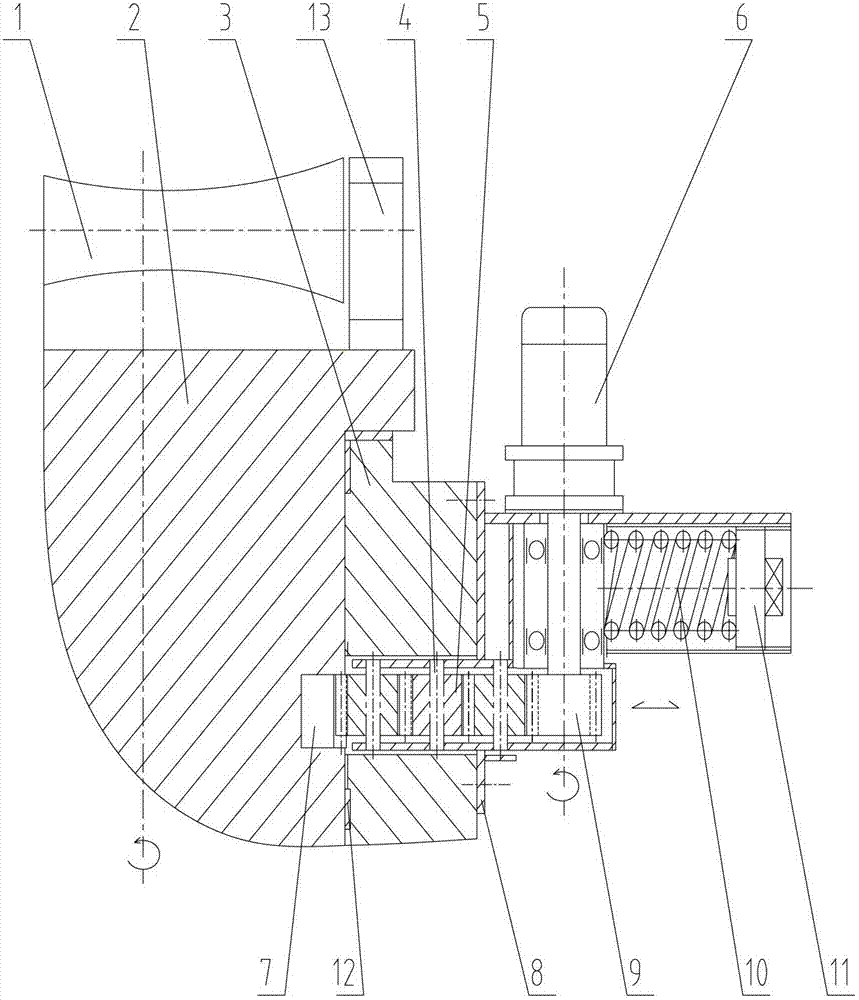

[0034] In conjunction with accompanying drawing, the specific embodiment of the present invention is described as follows:

[0035] Such as figure 1 , the straightening roller 1 is fixed on the roller seat 2 through the bearing seat 13 and multiple sets of bolts, and the roller seat 2 is positioned inside the frame 3 through two positioning bearings 12; when the roller seat 2 rotates in the frame 3, The angle between the straightening roller 1 and the rolled piece also changes accordingly. The wide band of the half ring gear 7 is greater than the width of the transition gear 5, which does not affect the lifting movement of the roller base 2 along its axis.

[0036] Angle adjustment device is made up of reduction motor 6, box body 8, spring 10, driving gear 10, adjustment bolt 11, half ring gear 7, eccentric shaft 4 and transition gear 5.

[0037] The roller seat 2 is positioned in the frame 3 , and the casing 8 of the angle-adjusting main transmission device is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com