Press fitting equipment for rubber bushing

A technology of rubber bushing and equipment, which is applied in the field of rubber bushing press-fitting equipment, can solve problems such as material box overturning, and achieve the effect of convenient material removal and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

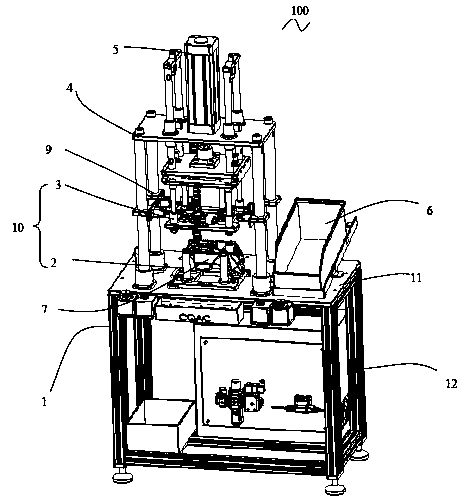

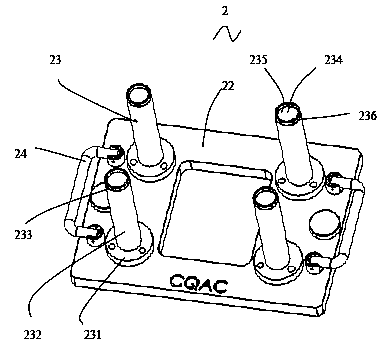

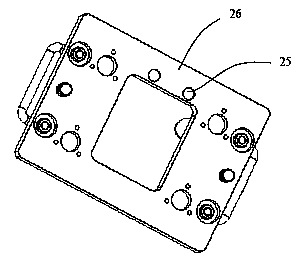

[0023] See Figure 1 to Figure 12 The rubber bushing press equipment 100 in an embodiment of the present invention is used to press a bush (not shown) into the workpiece 7. The rubber bushing press equipment 100 includes a frame 1, a lower clamp 2 fixed on the frame 1, an upper clamp 3 matched with the lower clamp 2 and arranged above the lower clamp 2, a stroke frame 4 for fixing the upper clamp 3, and used for pushing The driving device 5 for the upper clamp 3 to move up and down, and the bush accommodating device 6 fixed on the frame 1 and located beside the lower clamp 2 for storing the bush. The lower clamp 2 and the upper clamp 3 are combined to form a clamp group 10. The rubber bushing press equipment 100 can complete the tooling of three different types of workpieces 7, corresponding to three different types of workpieces 7, and corresponding to three different types of fixture groups 10. The frame 1 includes a worktable 11 and a frame body 12 for supporting the workt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap