Intelligent customization machine

A customized machine and intelligent technology, applied in printing, printing devices, etc., can solve the problems of occupying space, delaying time, standing for half an hour or drying in the sun.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

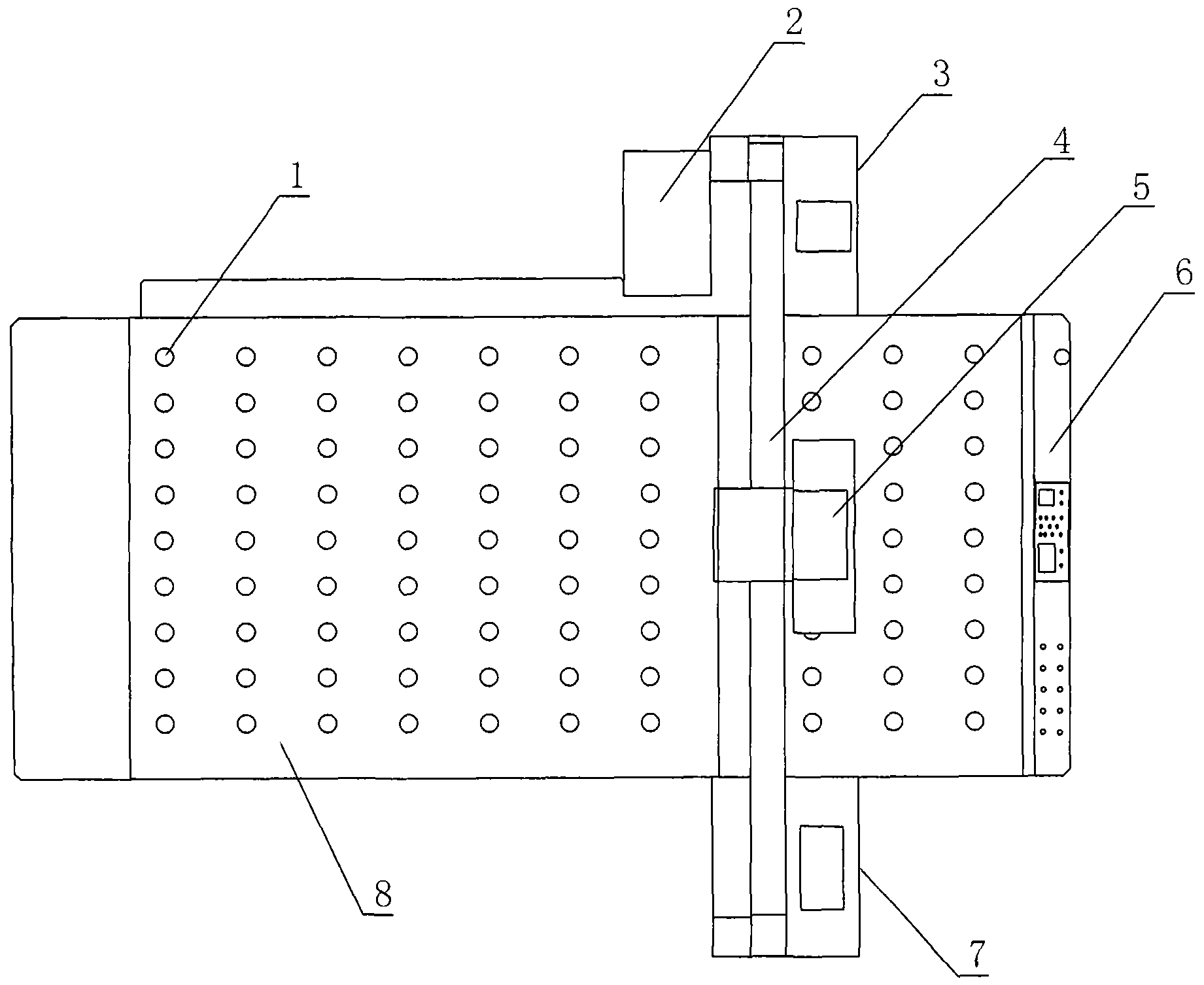

[0010] Example: such as figure 1 As shown, an intelligent customized machine includes a color printing device and an operating table 8. The color printing device is arranged on the operating table 8 and moves left and right through the guide rail 4. The color printing device consists of a main machine, a trolley head 5, Machine head 3, right machine head 7, ink cartridge 2, guide rail 4 and its accessories, characterized in that the console 8 is provided with a small hole 1 that penetrates up and down, and below the console 8 is provided with the main engine of the color printing device, a heating device and As for the air suction device, there are wall doors around the bottom of the operating table, and the wall doors surround the main engine of the color printing device, the heating device and the air suction device to form a closed space around. The front end of the console is provided with a front panel 6. A closed space is formed inside the surrounding wall doors. The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com