Mirror head

A mirror holder and lens technology, applied in optical observation devices, transportation and packaging, vehicle parts, etc., can solve problems such as increasing manufacturing costs, increasing production costs, and complicating assembly, and achieves the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

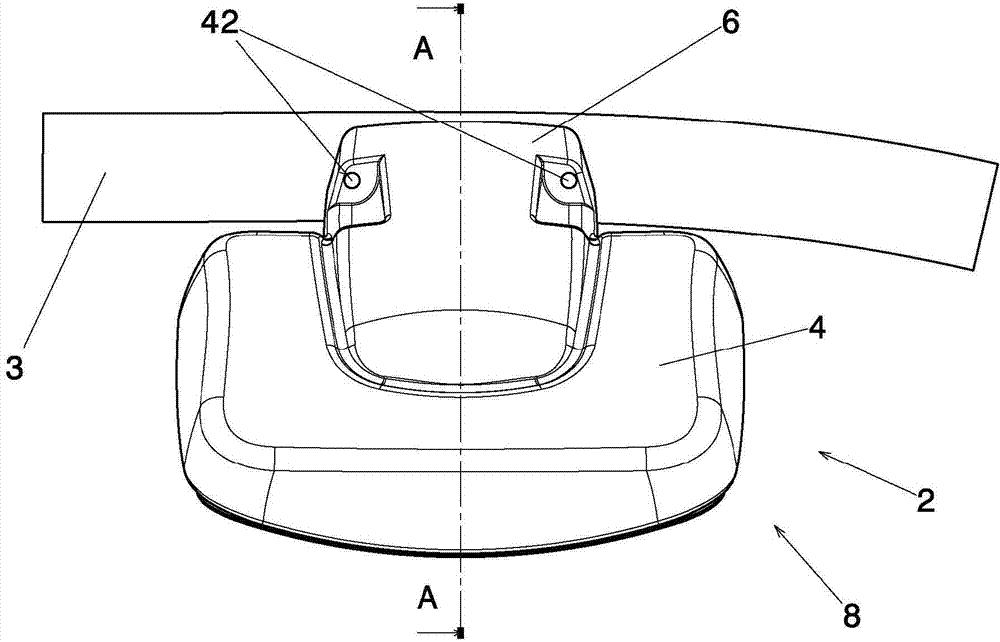

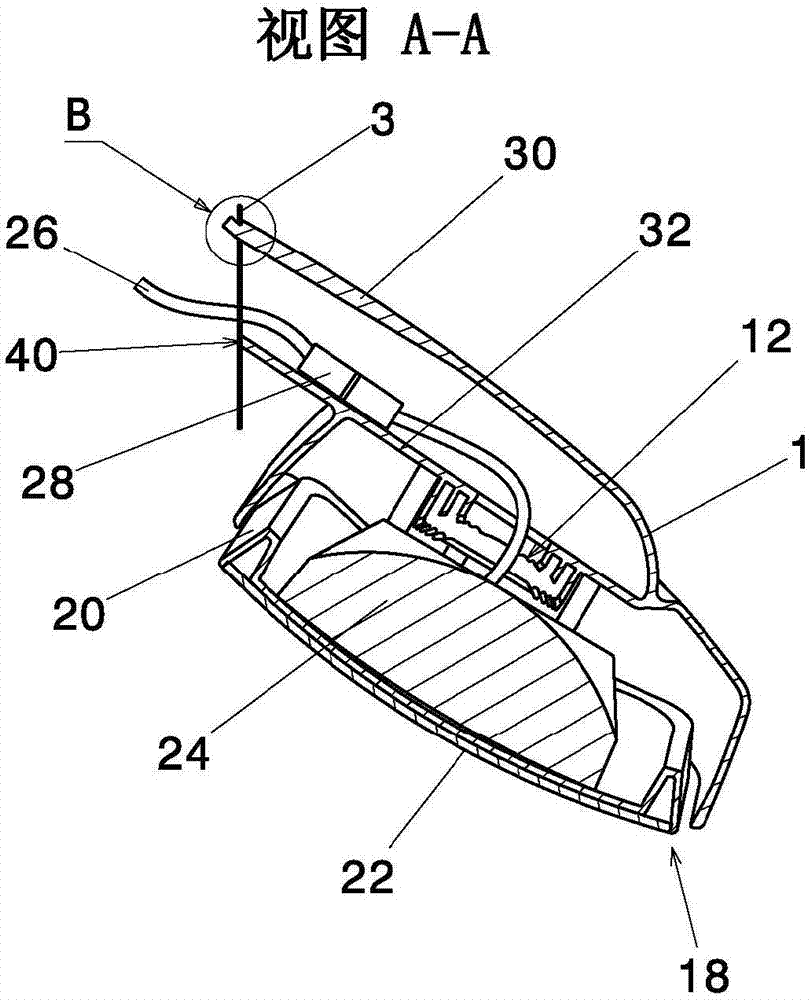

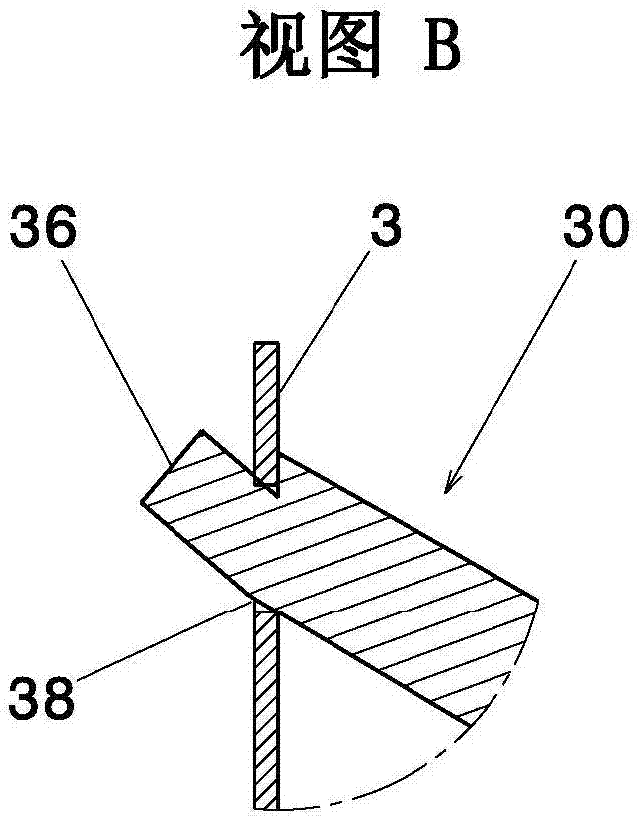

[0054] Figure 1 to Figure 4 Shown is a mirror mount 2 according to a first embodiment of the invention. The mirror mount 2 has been mounted to the outside surface of the vehicle 3 . The mirror base 2 includes a mirror cover 4 , and a cup-shaped terminal assembly 6 extending sideways is provided on the back of the mirror cover 4 . The mirror housing 4 and the terminal assembly 6 are an integrated element 8 forming a single piece. The mirror housing 4 is provided with a cup-shaped seat 10, in the interior of which a connecting region 12 is provided approximately centrally. The connection region 12 has first and second mounting elements 14 and 16 . The first mounting element 14 is used to mount the lens unit 18 . The lens unit 18 has a lens carrier plate 20 and a glass lens 22 , both of which can be adjusted in position. The second installation element 16 is used for installing the electric adjustment device 24 . The electric adjusting device 24 is powered by a cable 26 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com