Mounting structure of threshold decoration part

A technology for installing structures and decorative parts, applied in the direction of connecting components, vehicle parts, threaded fasteners, etc., can solve the problems of increased modeling restrictions in some areas, unfavorable body aesthetics, and increased manufacturing difficulty, and achieves simple and efficient assembly. The effect of reducing decoration requirements and strong assembly operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

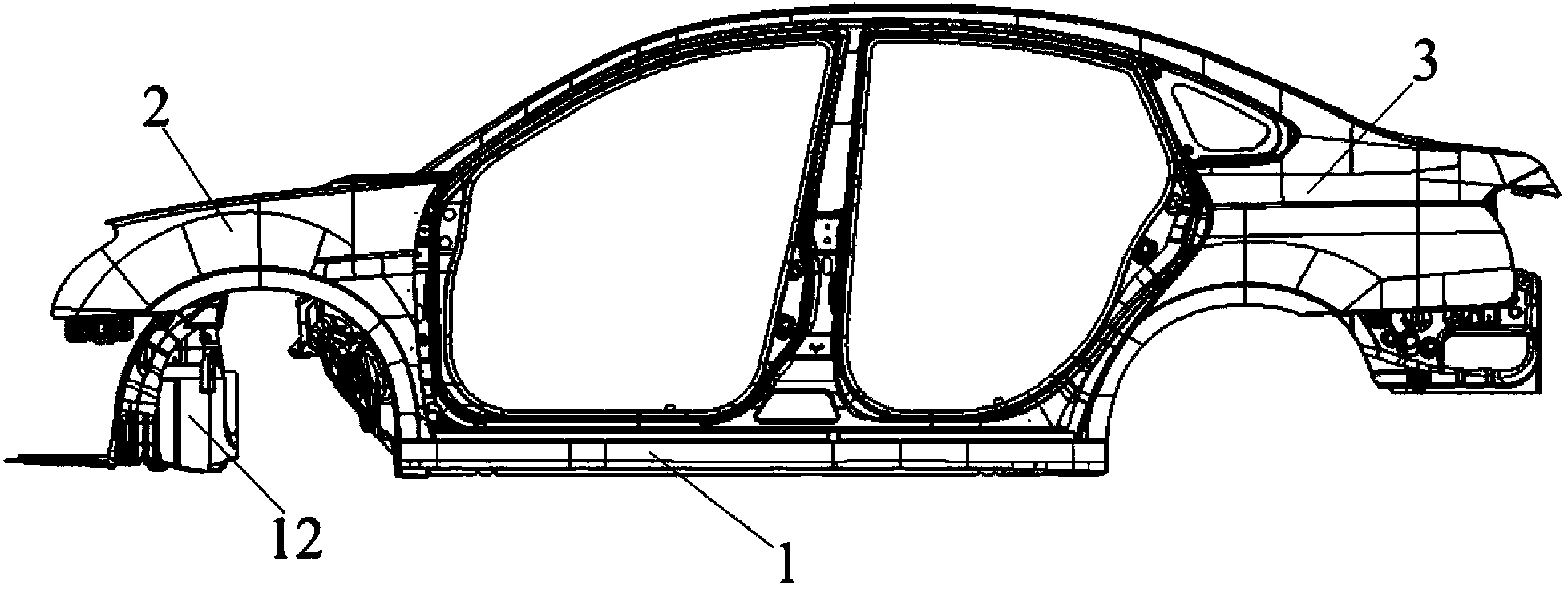

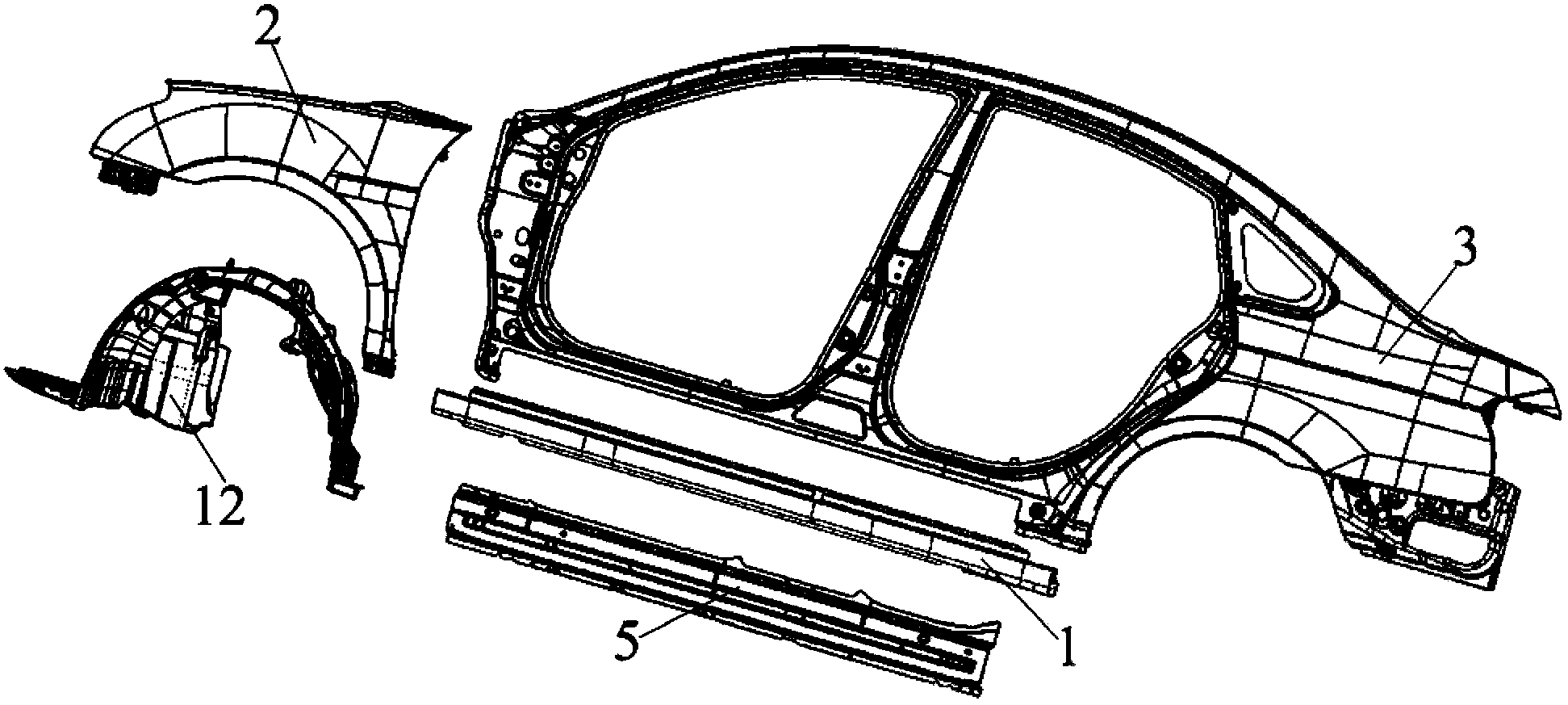

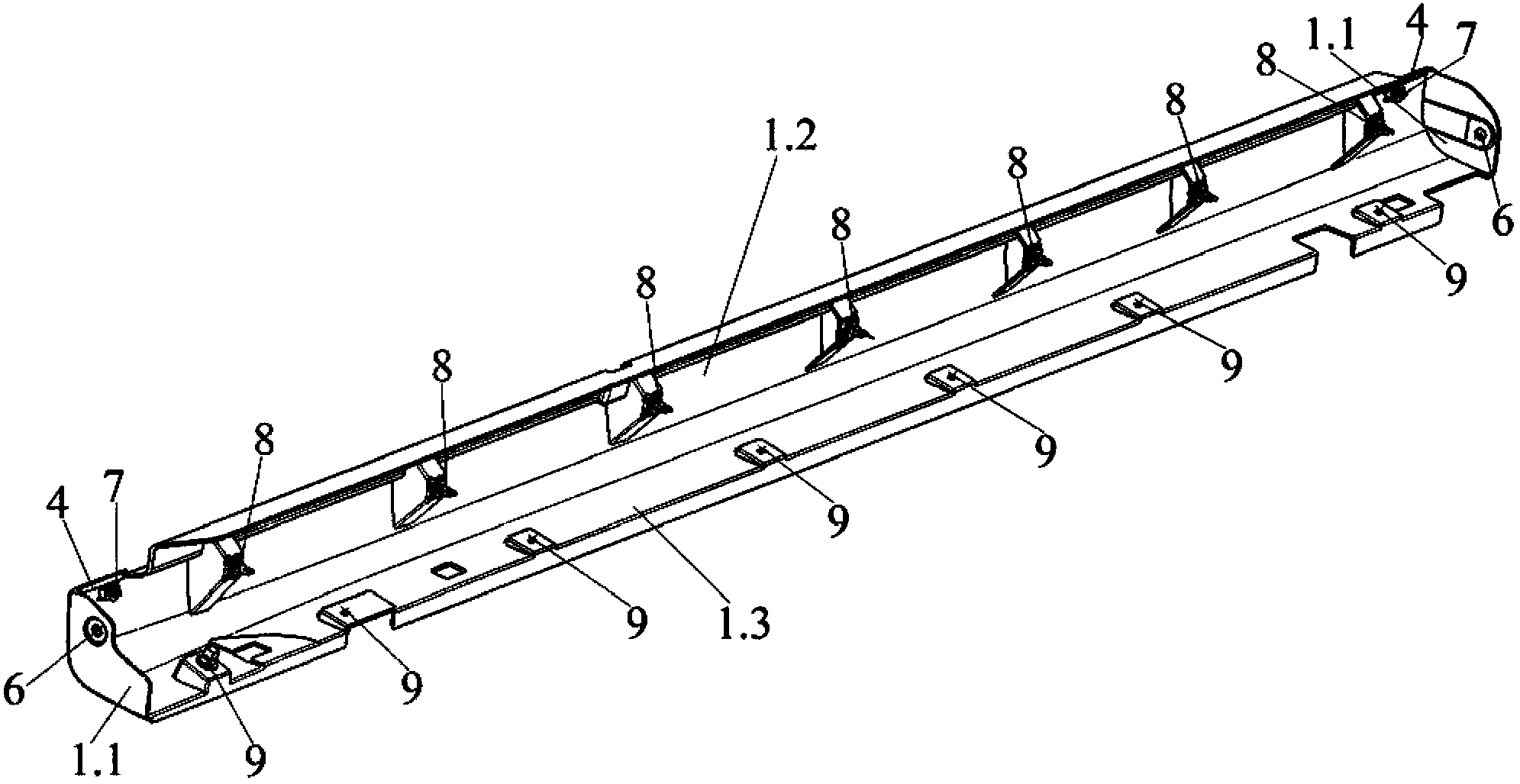

[0032] Figure 1~4 The installation structure of the door sill trim shown includes a door sill trim 1, and the door sill trim 1 includes end plates 1.1 at both ends, side plates 1.2 and bottom plates 1.3 connected to the end plates. The end panels 1.1 at both ends are provided with buckle components 6 that are snapped together with the front fender 2 and the side panel 3 respectively. Both ends of the side panel 1.2 are provided with first buckle components 7 that are respectively clamped to the front fender 2 and the side wall outer panel 3 . The side plate 1.2 is also provided with a plurality of second buckle components 8 that are engaged with the sill reinforcement crossbeam 5 . Two ends of the side plate 1.2 are provided with sealing rubber pads 4 above the first buckle assembly 7 . The bottom plate 1.3 is provided with a nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com