Edge sealing system device for packing machine

A system device, packaging machine technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of high manufacturing cost, complex structure, weak sealing, etc., to improve the stability of sealing and cutting, simple assembly and maintenance, Improve firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and the embodiments.

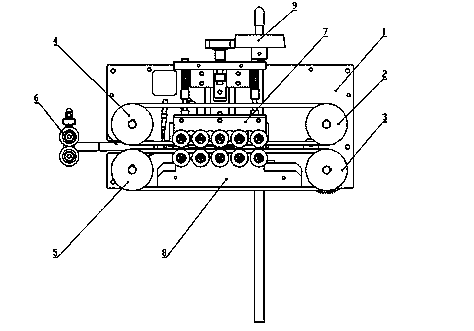

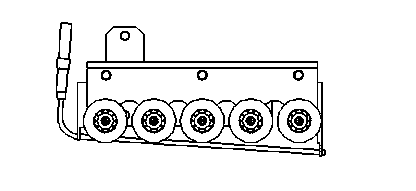

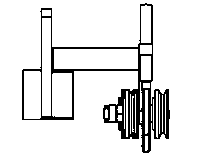

[0019] See figure 1 As shown, a side sealing system device for a packaging machine includes a mounting base plate 1. One end of the mounting base plate 1 is equipped with an upper driving pulley assembly 2 and a lower driving pulley assembly 3, and the other end is equipped with an upper driven pulley assembly 4 And a lower driven pulley assembly 5, an upper pressure belt pulley assembly 7 is installed between the upper driving pulley assembly 2 and the upper driven pulley assembly 4, the lower driving pulley assembly 3 and the lower driven pulley assembly 5 A lower pressure belt pulley assembly 8 is installed between the upper pressure belt pulley assembly 7 and the lower pressure belt pulley assembly 8 is installed between the side seal film clamping wheel assembly 6 and the upper pressure belt pulley assembly 7 is connected to the integral lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com