Horizontal sealing top knife and sealing knife guard board friction limiting device used for packing machine

A technology of limiting device and packaging machine, applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of affecting the sealing and cutting effect, high failure rate, easy jamming of the two side guards, etc., to improve the stability. , Easy to install and easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

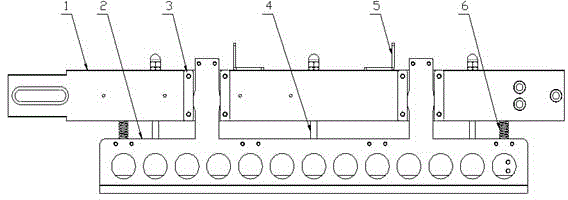

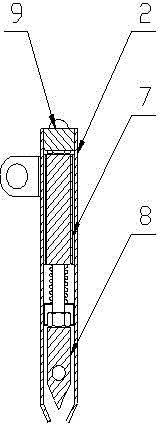

[0016] refer to figure 1 and figure 2 As shown, a horizontal sealing upper knife sealing knife guard plate friction limiting device for packaging machines includes an upper beam 1, and the upper beam 1 is connected with a sealing knife guard plate 2 through a horizontal knife hoisting bolt 4. There is also a nickel-plated pressure spring 6 for lifting the sealing knife guard 2 between the upper beam 1 and the sealing knife guard 2, and a friction copper plate 7 is installed on the inner side of the sealing knife guard 2, and the two sides of the middle section of the upper beam 1 An anti-cut induction bracket 5 is fixed on the side, a horizontal knife 8 is provided at the bottom of the sealing knife guard plate 2, and a mounting block 9 is provided at the top.

[0017] Further, the installation place of the friction copper plate 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com