Loading device for local punching performance test of high-strength grouting material restrained by round steel pipe

A technology of loading device and grouting material, which is applied in the direction of measuring device, strength characteristics, analyzing materials, etc., can solve the problem of lack of a large number of sufficient and reliable test data, etc., and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention.

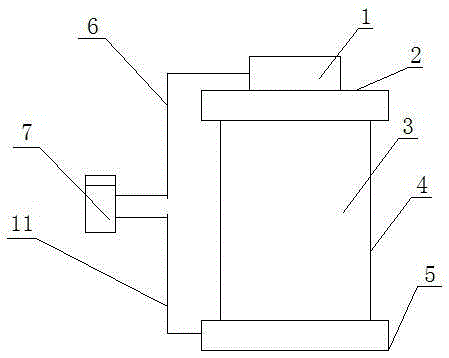

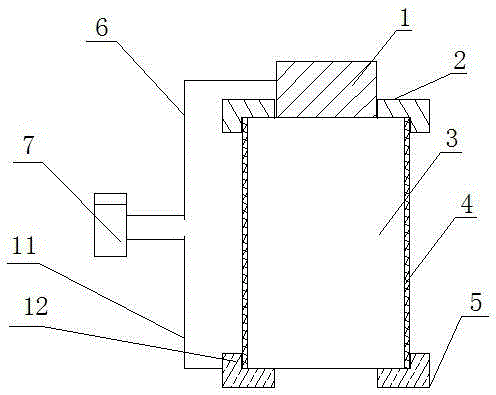

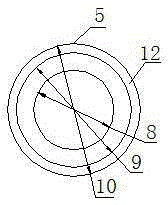

[0023] see figure 1 , figure 2 , image 3 , the local stamping performance test loading device of the high-strength grouting material constrained by the round steel pipe given in this embodiment includes a material fixing cylinder 4, an upper loading positioning snap ring 2, a lower loading positioning snap ring 5, a circular loading plate 1, and an upper load transmission Rod 6, lower load transmission rod 11, extensometer 7; the lower end of the material fixing cylinder 4 is socketed in the lower loading positioning snap ring 5, and the upper end of the material fixing cylinder 4 is socketed in the upper loading positioning snap ring 2, and the material The grouting material test piece 3 is inside the fixed cylinder 4; the circular loading plate 1 is placed on the upper surface of the grouting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com