Method and device for calculating fatigue life of vehicle welding lines

A technology of fatigue life and calculation method, applied in the field of machinery, can solve the problem of large error in the analysis data of weld fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

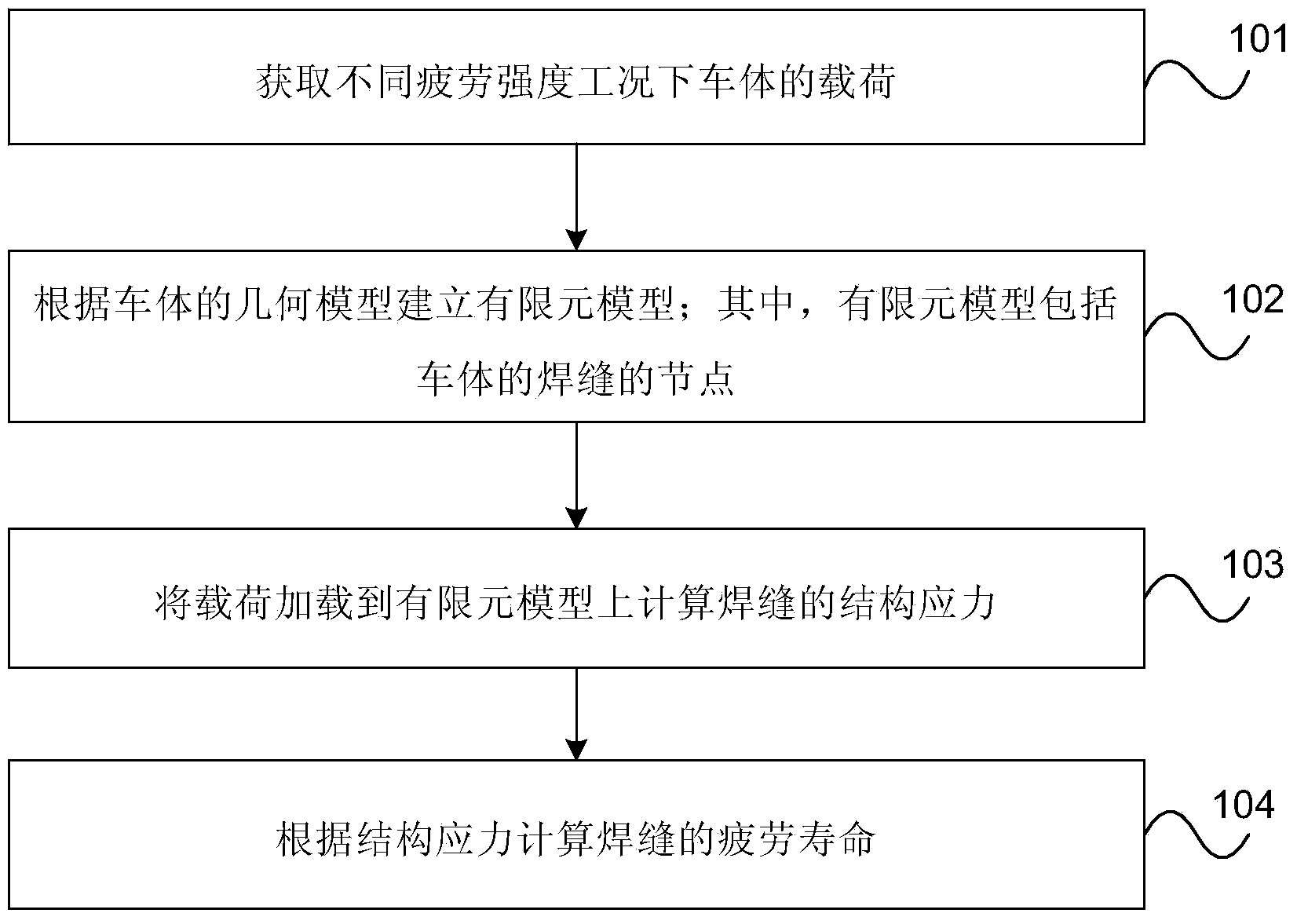

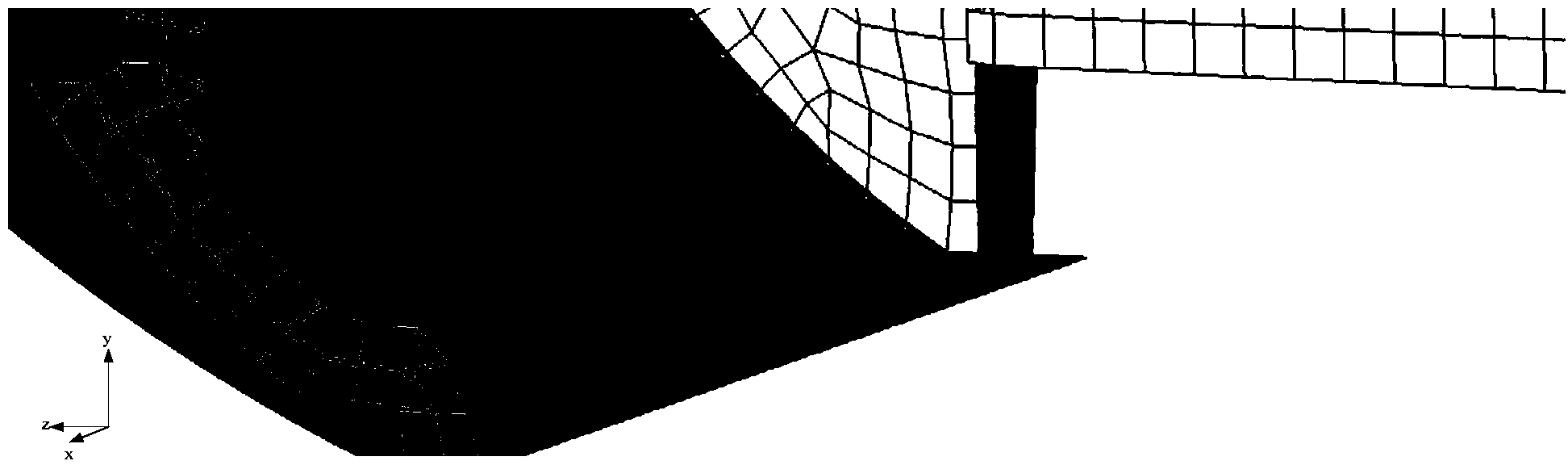

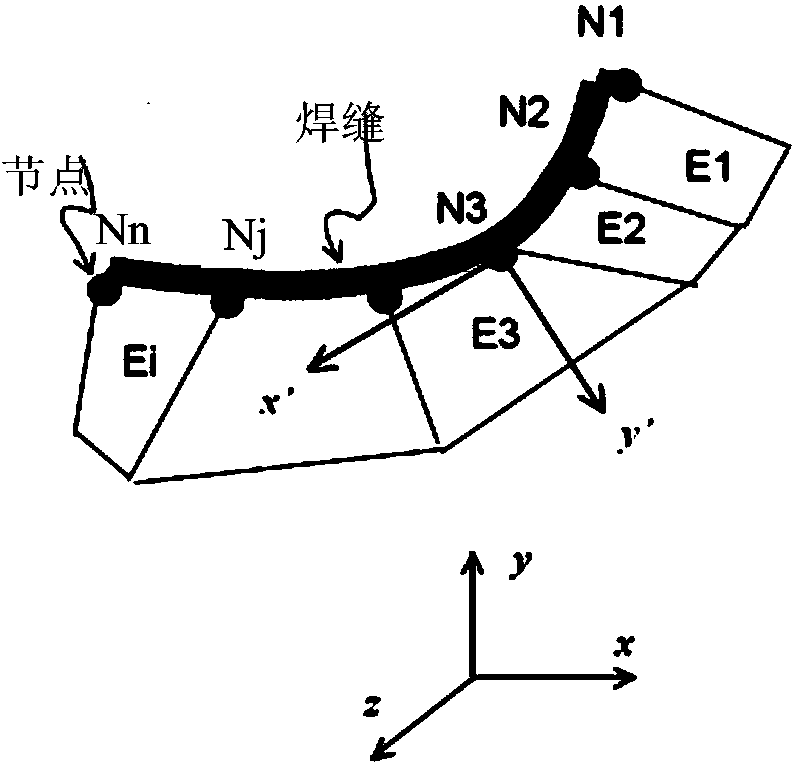

[0038] figure 1 It is a flow chart of Embodiment 1 of the method for calculating the fatigue life of a car body weld seam according to the present invention. figure 2 It is a schematic diagram of the car body weld in the first embodiment of the method of the present invention Figure 1 . image 3 It is a schematic diagram of weld joints in Embodiment 1 of the method of the present invention. Such as figure 1 As shown, the method of this embodiment may include:

[0039] Step 101, obtaining the loads of the vehicle body under different fatigue strength conditions.

[0040] Specifically, the application object of the embodiment of the present invention can be the high-speed train aluminum alloy TC intermediate car body model CRH3-380. Based on the car body online test standard, the loads of the car body under different fatigue strength conditions on the actual line are obtained, as follows Table 1 shows:

[0041] Table 1 Load list of car body under different fatigue streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com