Isolation-switch contact-finger dismounting device

A technology of isolating switches and contact fingers, which is applied in the direction of switchgear, electric switches, electrical components, etc., can solve the problems of difficult operation, damage to related components, damage to contact fingers and springs, etc., and achieve the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

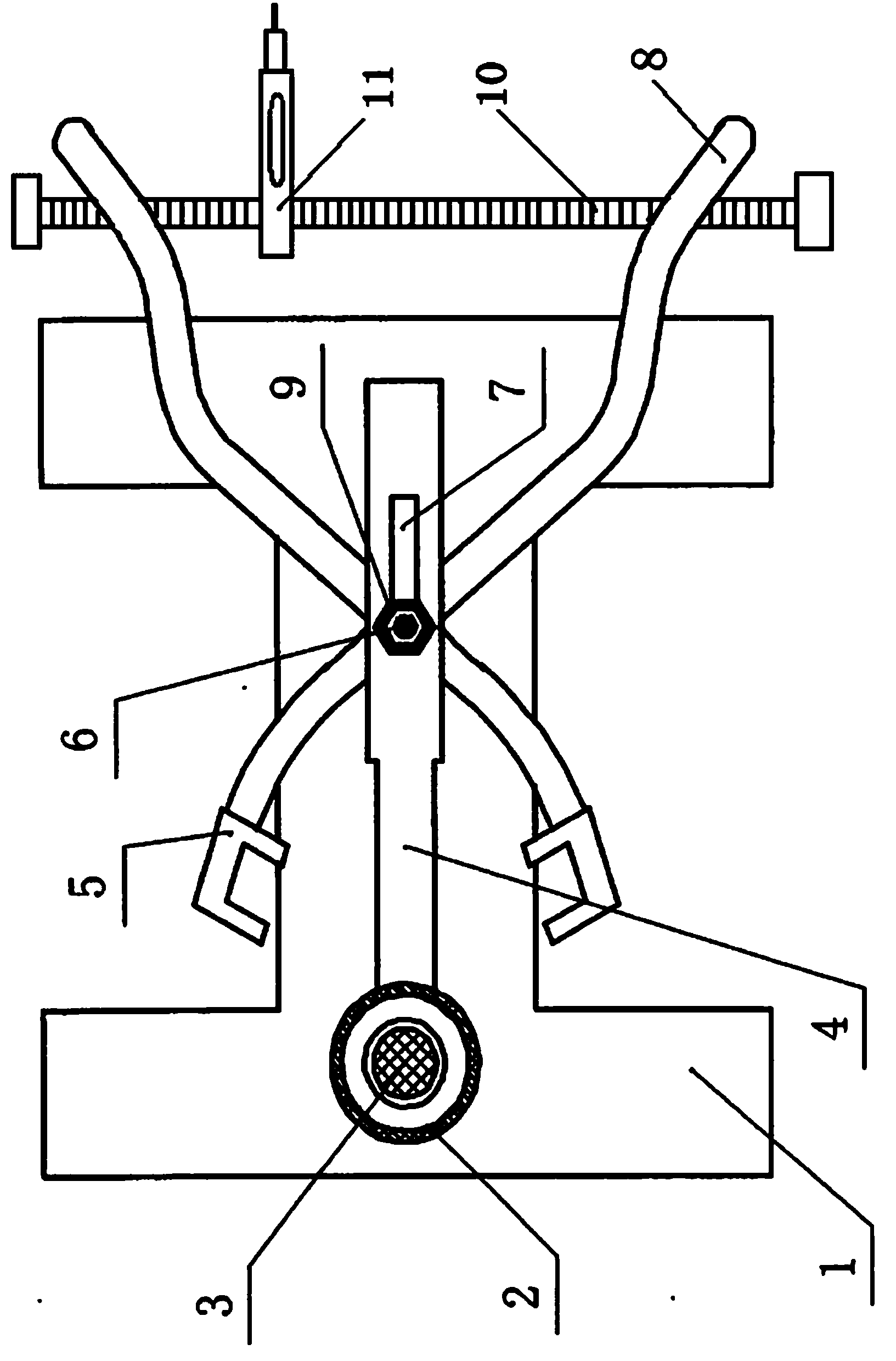

[0009] like figure 1 As shown, the present invention includes a base 1 and a handle 8, and the two handles 8 are hinged by a hinge shaft 6; a circular shaft 3 is vertically arranged on the base 1, and a positioning rod 4 that can move along it is arranged on the hinge shaft 6, and the positioning rod 4 The front end is provided with a circular ring 2, and the circular ring 2 is set on the round shaft 3; a chute 7 is provided at the rear of the positioning rod 4, and the hinge shaft 6 is located inside the chute 7. Simultaneously, the nut 9 that can prevent the positioning rod 4 from coming off is screwed on the hinge shaft 6 .

[0010] The present invention is provided with contact finger buckle 5 at the end of handle 8, and screw rod 10 is arranged between two handles 8, and adjusting handle 11 is arranged on screw rod 10, like this, when dismounting spring, can pull slowly Adjust the handle 11 so that the adjustment handle 11 moves on the screw rod 10, thereby slowly adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com