Clapboard paper cutting mechanism

A technology of partition paper and cutting knife, which is applied in the direction of structural parts, electrical components, circuits, etc., to achieve the effect of smooth surface, good use value and avoid discount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

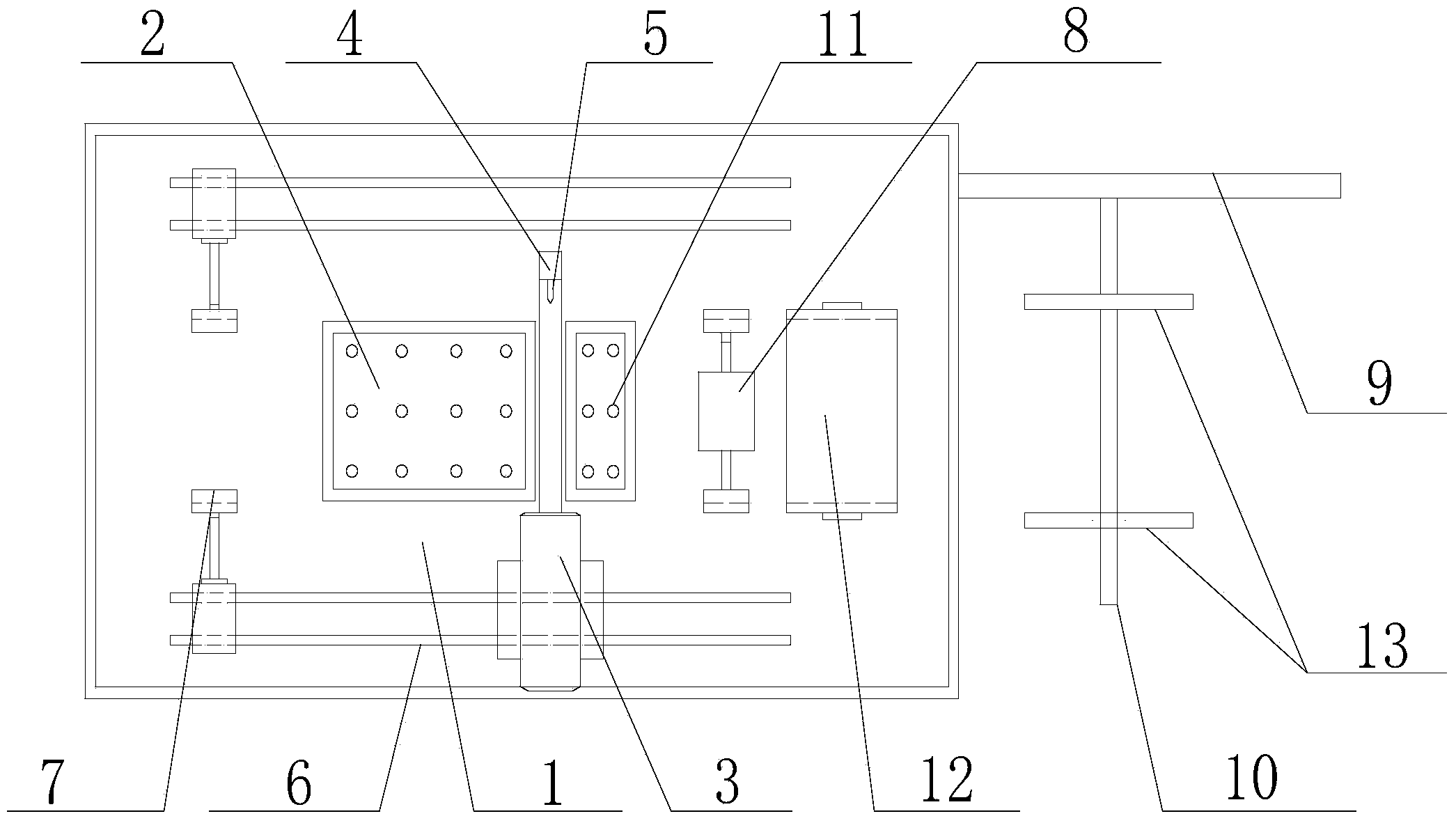

[0011] Embodiment of the present invention: a partition paper cutting mechanism, as shown in the accompanying drawings, includes a fuselage 1, and a first suction plate 2 that can move up and down is installed in the middle of the fuselage 1. The first suction plate 2 A cylinder 3 is installed on the lower right side, the head end of the push rod of the cylinder 3 is connected with a vertical rod 4, the head end of the vertical rod 4 is installed with a cutting knife 5, and a track is installed on the front and rear sides of the fuselage 1 6. A movable clamping mechanism 7 is installed on each track 6, a fixed clamping mechanism 8 is installed on the upper right side of the fuselage, and a mounting rod 9 is installed on the side wall of the right fuselage 1, One inserting rod 10 is installed on the mounting rod 9 .

[0012] A second suction plate 11 that can move up and down is installed on the right side of the cutting knife 5 .

[0013] On the right side of the fixed clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com