Corrugated vibrating screen

A corrugated, vibrating screen technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problem that the passing capacity of the vibrating screen cannot be well applied to different types of crops, and it is not conducive to the harvesting of different types of crops, so as to achieve good production results , reduce the loss of grain, improve the effect of cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

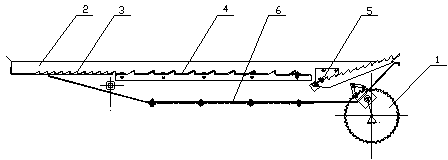

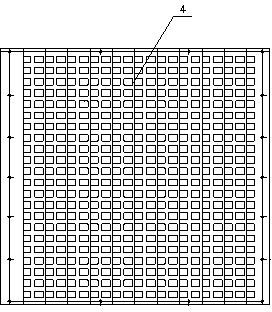

[0016] Such as figure 1 and figure 2 As shown, this embodiment provides a corrugated vibrating screen, including a screen frame 2, a corrugated plate 3 for layering materials, an upper woven screen 4 for separating grains and sundries from materials, a tail screen 5 and a lower screen. The sieve 6, the corrugated plate 3, the upper woven sieve 4, and the tail sieve 5 are sequentially arranged in the sieve frame 2 from front to back, and the upper woven sieve 4 and the lower sieve 6 are arranged in the sieve frame 2 in turn Inside, the upper woven screen 4 adopts a corrugated upper woven screen. The upper woven screen 4 adopts a square hole screen. The distance between adjacent corrugations of the upper woven screen 4 is 8-25 cm, preferably 12 cm. The screen frame 2 is connected with an eccentric drive mechanism 1 for reciprocating the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com