Resin molded product and molding method and molding apparatus thereof

A technology of resin molding and molding equipment, which is applied in the field of resin molded products, can solve the problems of troublesome molding operations, lower molding quality, and poor resin filling properties, so as to simplify the structure, improve molding quality, and prevent the reduction of resin filling properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

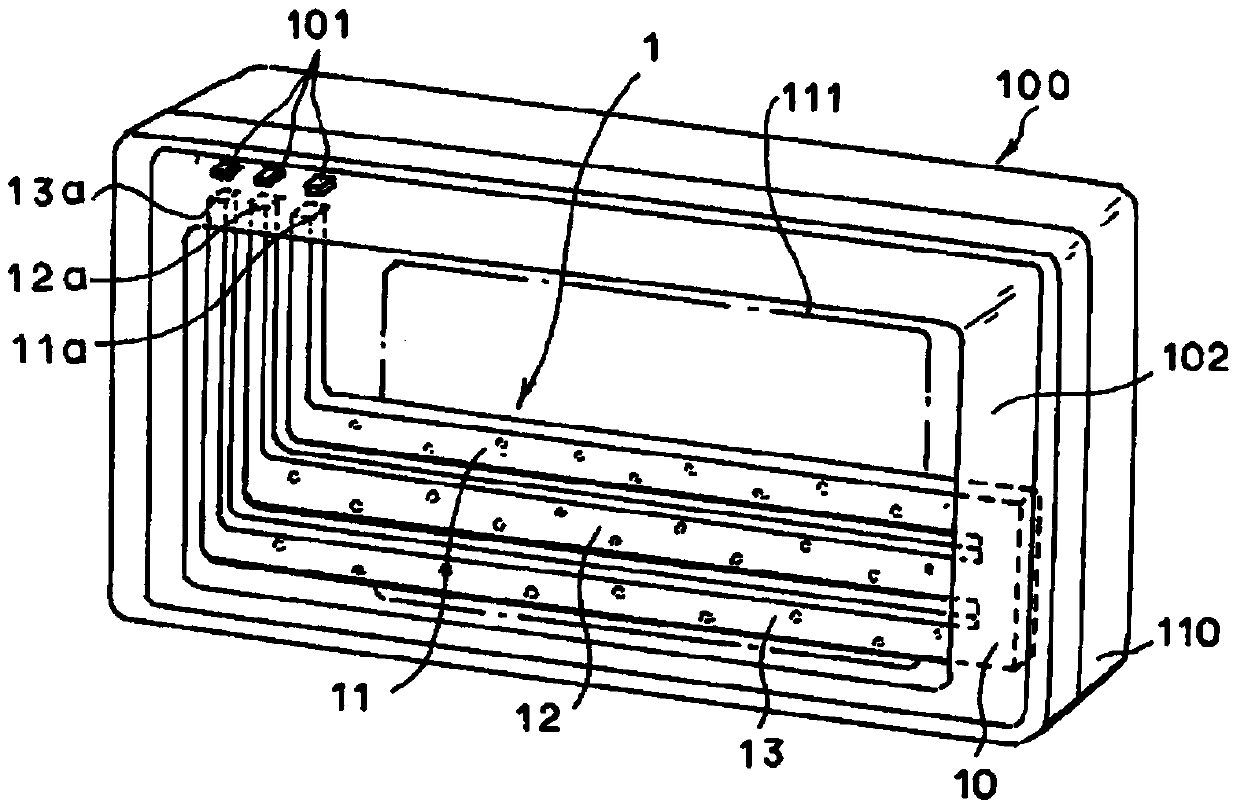

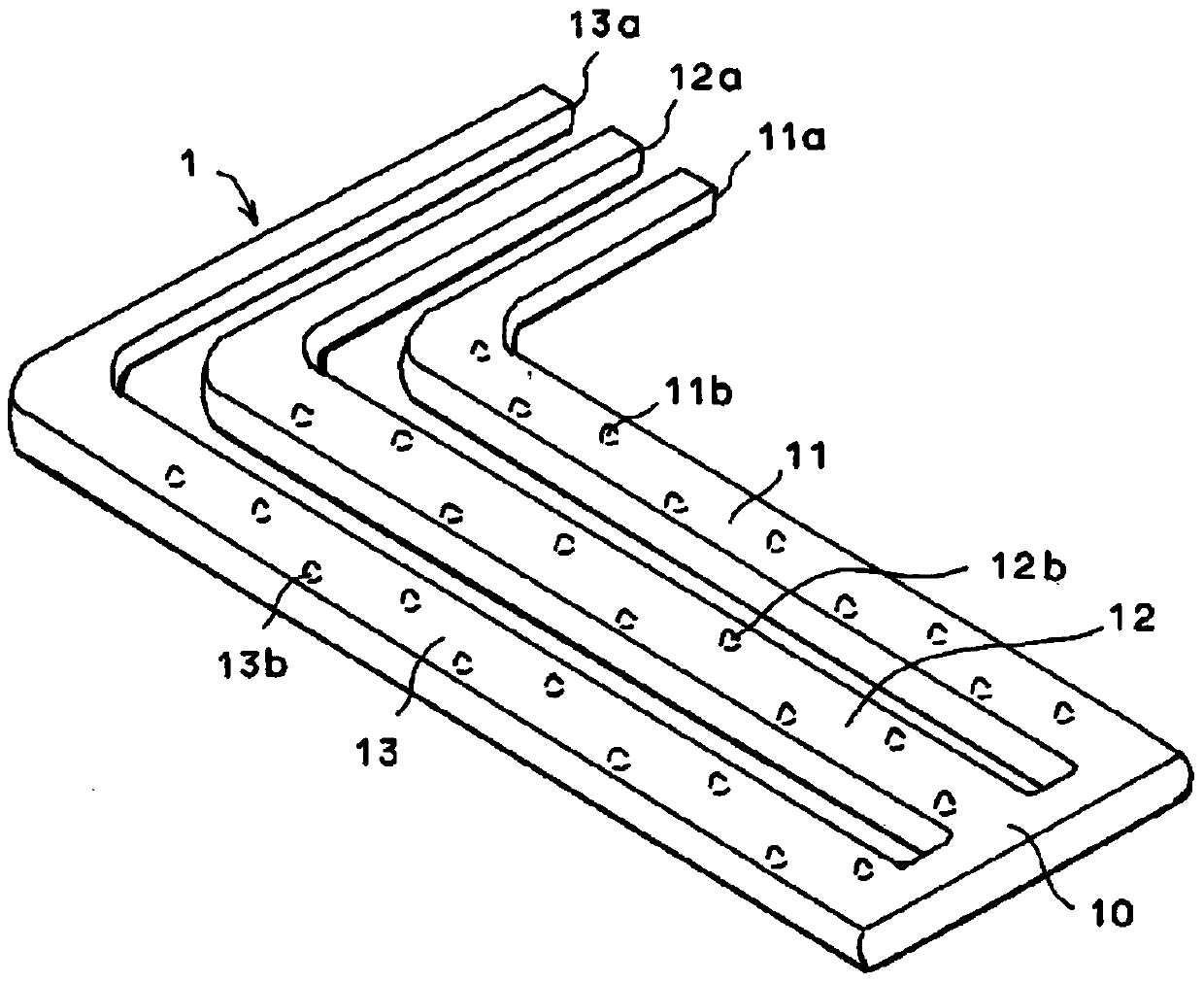

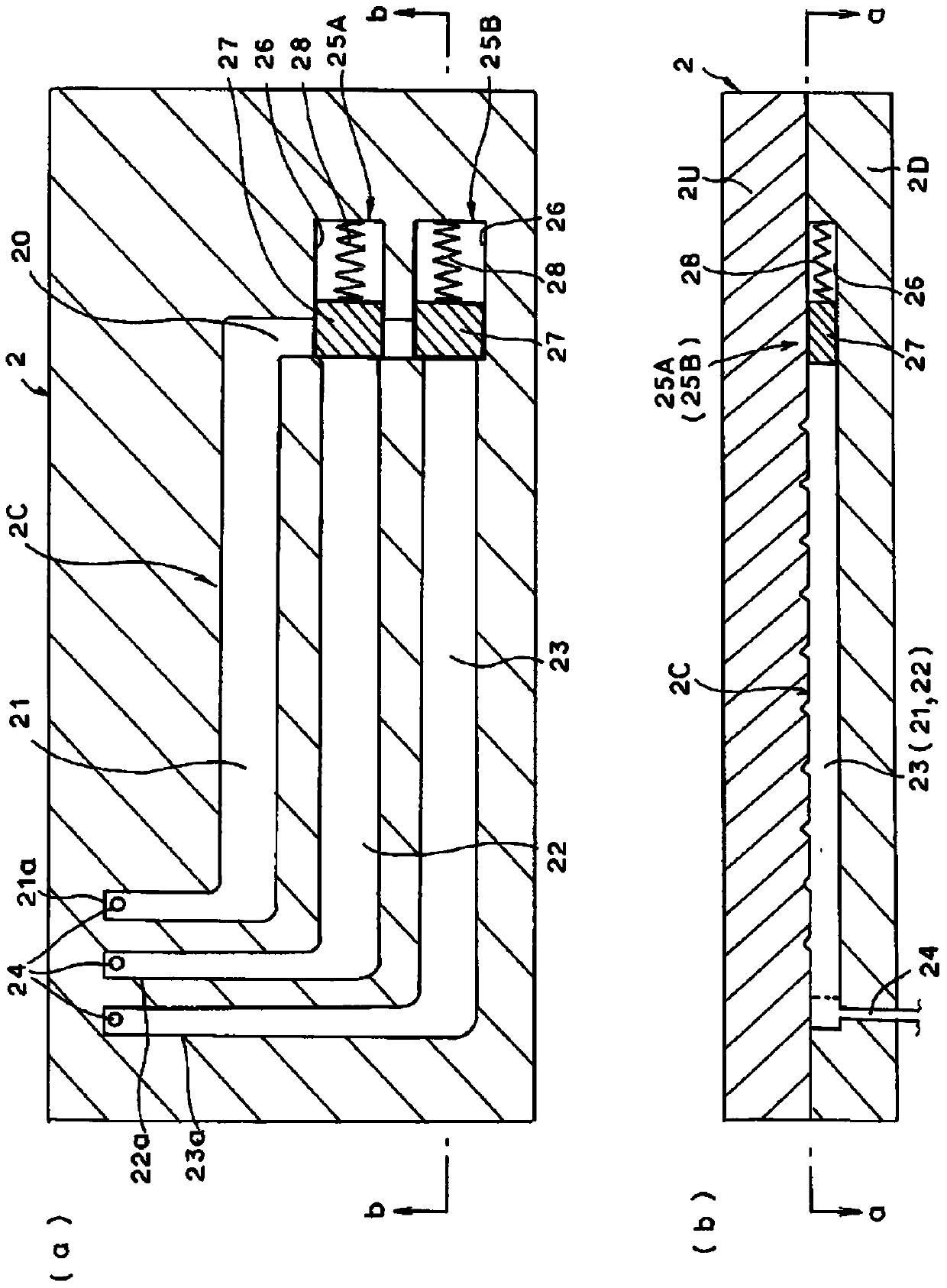

[0039] Hereinafter, one embodiment of the present invention will be described with reference to the drawings. In the present embodiment, an example of the photoconductor 1 comprising the resin molded product of the present invention as a curved comb shape will be described, that is, the figure 1 The respective front ends of the plurality of molded parts shown are formed by being connected at a connecting part. That is, the photoconductor 1 as figure 2 As shown, there are three substantially L-shaped forming parts 11, 12, 13, the base end side regions of the forming parts 11, 12, 13 are formed in a narrow width and the front end side regions are formed in a thick width, and these forming parts are formed in each The front ends are connected by a connecting part 10 . The photoconductor 1 is in the figure 1 When it is arranged in the lamp 100 as shown, the light emitted from the light source 101 arranged opposite to the base end is guided to the inside of the molding parts 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com