Metal printing technology for food metal can

A technology of metal cans and crafts, applied in printing, printing devices, and post-processing of printing, etc., can solve the problems of low anti-rust ability, low rate of qualified products, low production efficiency, etc., and achieve the effect of strong anti-rust ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

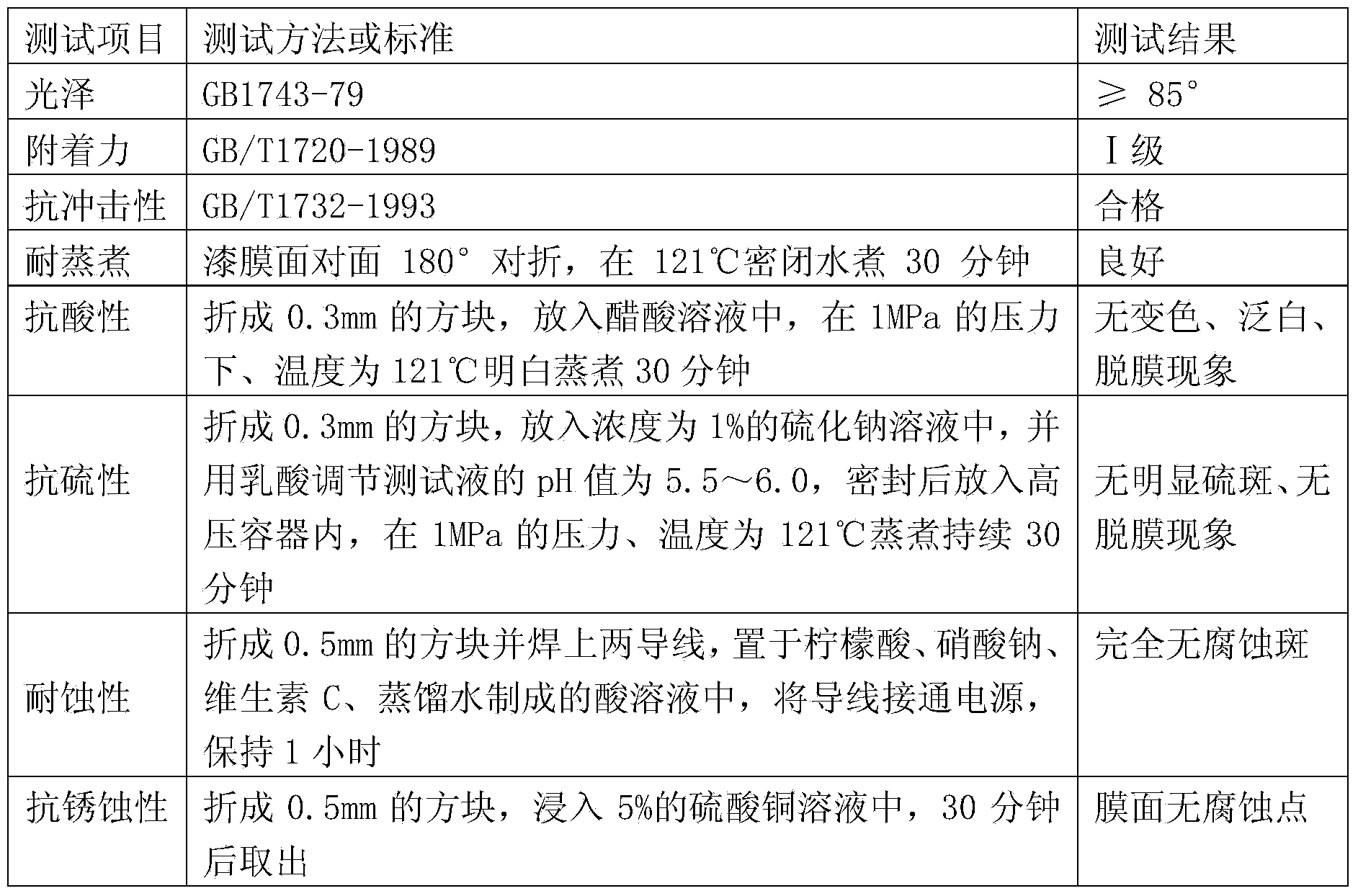

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described below to facilitate the understanding of those skilled in the art.

[0016] An iron printing process for food metal cans, including the following steps:

[0017] (1) Design and plate making, design the film pattern according to the sample, then stick the film on the ps plate for printing, and expose the ps plate for 110 seconds before developing;

[0018] (2) Substrate treatment, using tinplate thin steel plate, first blow off the sundries on the surface of the steel plate through a high-pressure air gun nozzle, and then rinse the steel plate in an alcohol solution for 10 minutes to remove oil and dust on the surface of the steel plate, and place the steel plate Dry in the air;

[0019] (3) Anti-rust treatment on the surface of the steel plate, apply anti-rust primer on both surfaces of the steel plate, with a dry film amount of 5-6g / m2, and bake at 150℃ for 20 minutes;

[0020] (4) Steel plate background color tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com