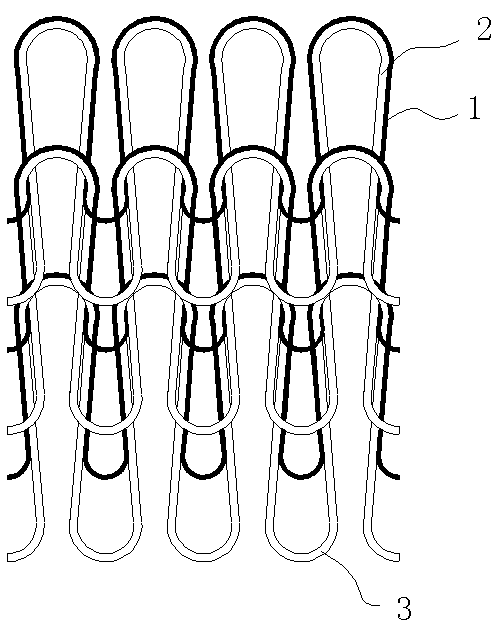

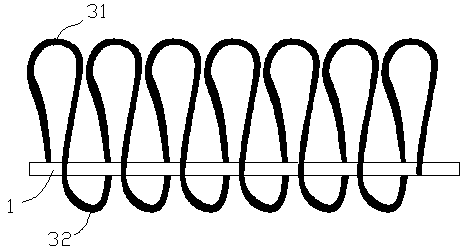

Printing double-resistant double-sided fabric and production method thereof

A fabric and printing technology, applied in the field of textile fabrics, can solve the problems of no moisture absorption and perspiration function, not suitable for close-fitting clothing fabrics, etc., and achieve the effect of soft and warm texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Described sweat-absorbing quick-drying agent is the Passerlle of U.S. Dow Corning, and consumption is 3% (O.W.F).

Embodiment 2

[0020] Described sweat-absorbing quick-drying agent is the HSD of U.S. Huntsman, and consumption is 3% (O.W.F).

[0021] The fabric is light and soft, has moisture absorption and quick-drying performance, and the clothes made are close to the skin, with a soft and warm texture. At the same time, the printing makes the fabric more beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com