Dyeing and finishing process of Porel antibacterial viscose pique eyelet fabric

A technology of pique mesh cloth and viscose, which is applied in the fields of dyeing, textiles and papermaking, and can solve the problems of large color variation and unstable fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. In addition, in the following description, descriptions of known technologies are omitted to avoid unnecessarily confusing the concept of the present invention.

[0026] Here, it should also be noted that, in order to avoid obscuring the present invention with unnecessary details, only process steps closely related to the solution according to the present invention are shown in the drawings.

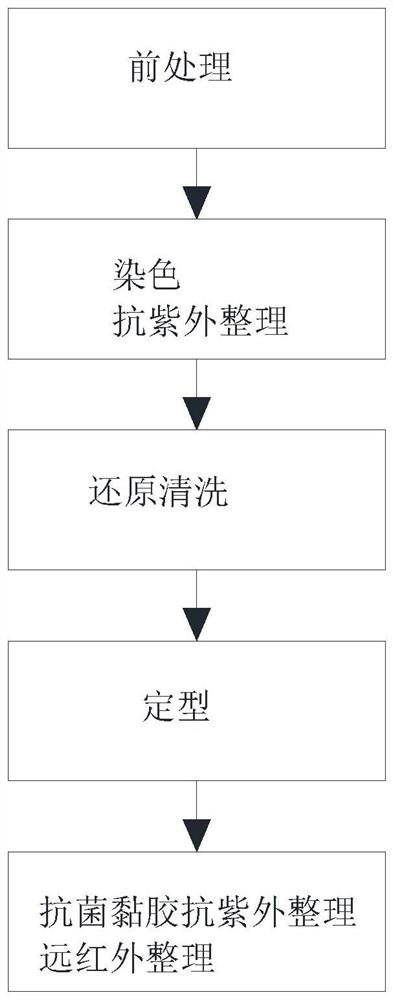

[0027] see as figure 1 As shown, a kind of Porel antibacterial viscose pearl ground mesh cloth dyeing and finishing process described in this specific embodiment adopts the following process flow:

[0028] Pretreatment→dyeing (Porel anti-u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com