Optical fiber-type optical functional element cartridge module

A technology of optical functions and optical components, applied in the directions of optical components, optics, electrical components, etc., can solve the problems such as the inability to amplify the optical signal, and the optical coupling cannot be obtained by the optical fiber collimator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

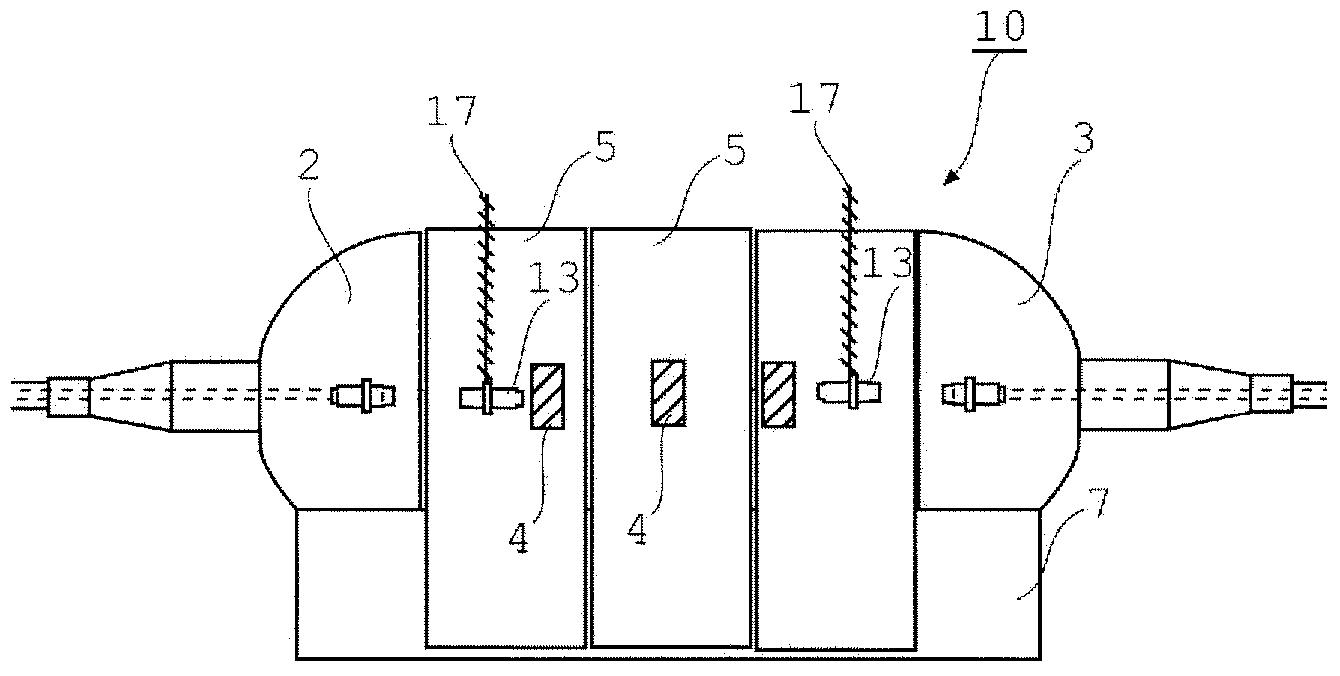

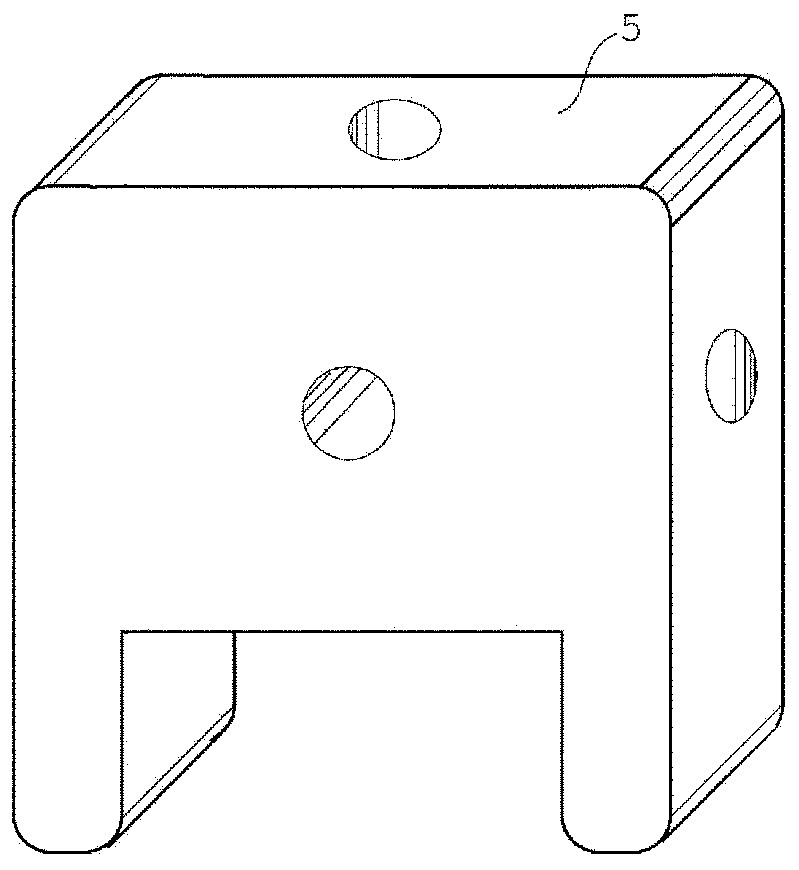

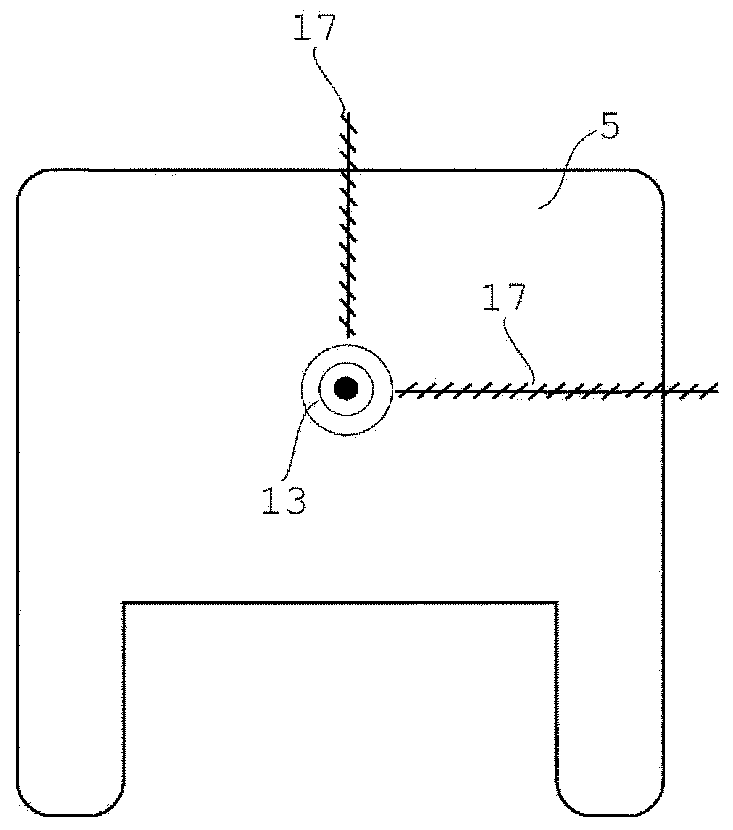

[0021] In the present invention, at least the component boxes located at both ends of the module have collimators. In addition, the present invention, for example, improves the component box to allow fine adjustment of the position of the collimator. A collimator insertion portion is provided at the center of the component box, and an adjustment mechanism is provided in a hole located above it and a hole extending in a lateral direction. Therefore, when the module is actually set up, after installing multiple component boxes on the substrate, the position of the collimator can be adjusted so that the optical coupling of each component box and the optical coupling of the fiber collimator can reach the best state. The adjustment mechanism is, for example, a screw that can be manually operated to move, or an actuator (Actuator) that can move a position by an electric command. The position of the collimator can be optimized by this adjustment mechanism, so even if a fiber-type or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com