Method and device for manufacturing an array line laser quantum dot backlight module

A technology of backlight module and line laser, which is applied in the direction of lighting devices, nonlinear optics, components of lighting devices, etc., to achieve the effect of reducing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described below in conjunction with accompanying drawing:

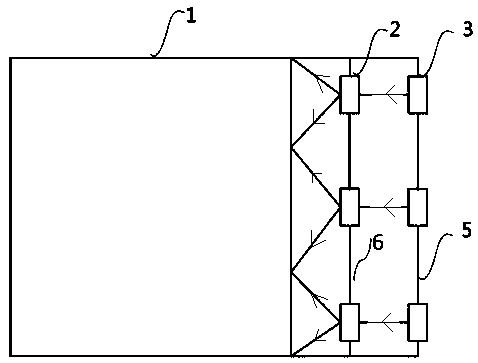

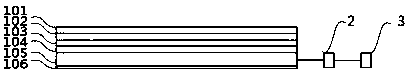

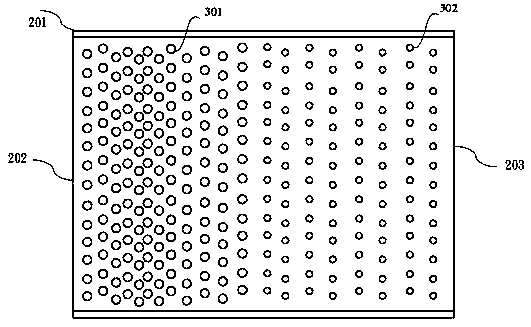

[0040] figure 1 It is an overall structure of an array line laser quantum dot light emitting device and a backlight module. It includes the blue laser light source 3 on the right, and the inner side of the laser light source is an arrayed prism group, that is, an arrayed Powell prism group 2, a light guide plate 105, a quantum dot film group, and subsequent optical coupling components.

[0041] Among them, the blue laser light source is composed of semiconductor lasers. In order to reduce the temperature increase that may be caused by long-term exposure, the blue laser light source is equipped with a special heat dissipation structure, which consists of ordinary air heat sink guide grooves along the end of the laser module from left to right, which are not shown in the figure out.

[0042] The number of arrayed laser light sources is determined by the size of the light guide plate 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com