Device and method for processing food by utilizing high-voltage pulse sensing current

A technology of pulse current and high voltage pulse, which is applied in the field of food processing, can solve the problems of small scope of application, damage to food nutrition and flavor, etc.

Active Publication Date: 2014-06-18

江苏合心医疗科技有限公司

View PDF11 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The purpose of the present invention is to provide equipment for processing food using high-voltage pulse induction current, which solves the problem that the existing heat sterilization method wil

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

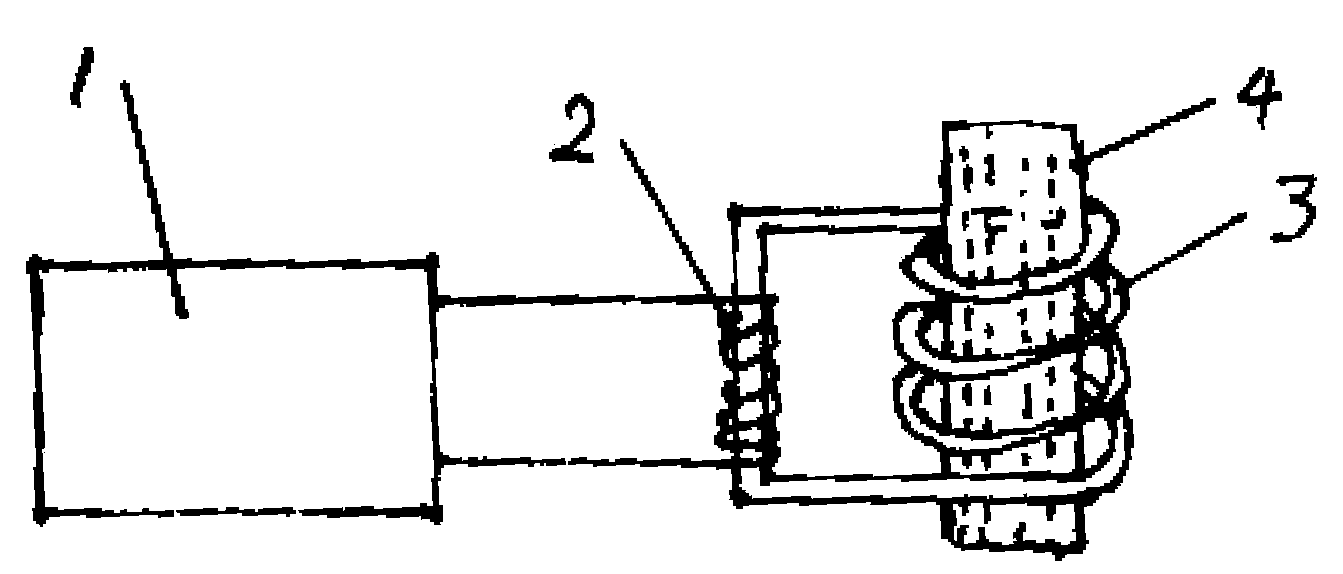

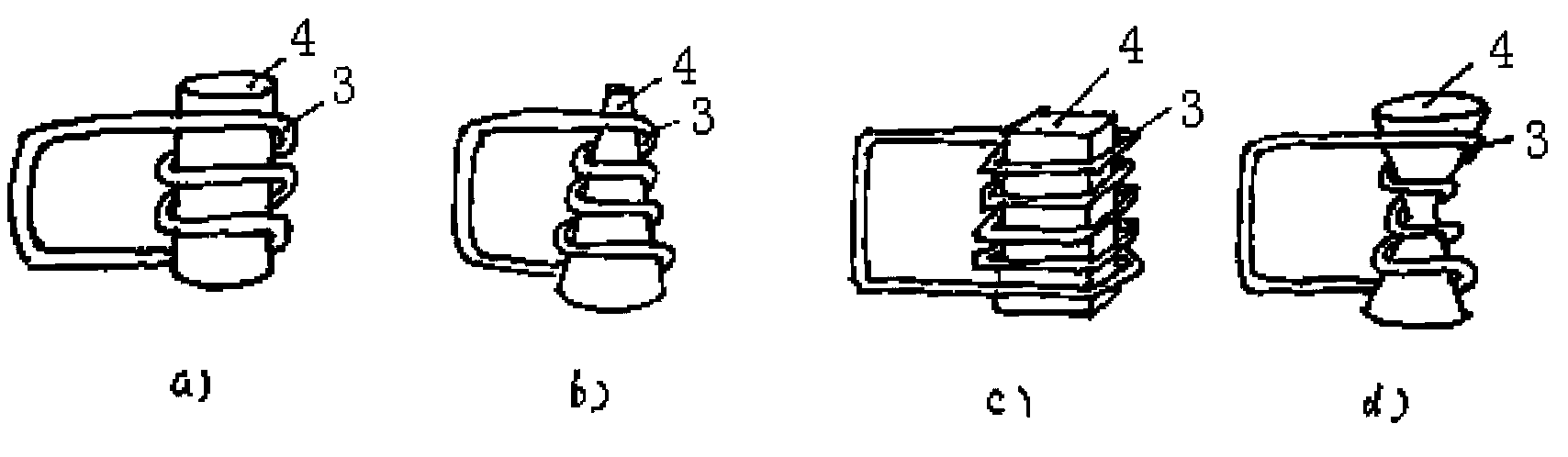

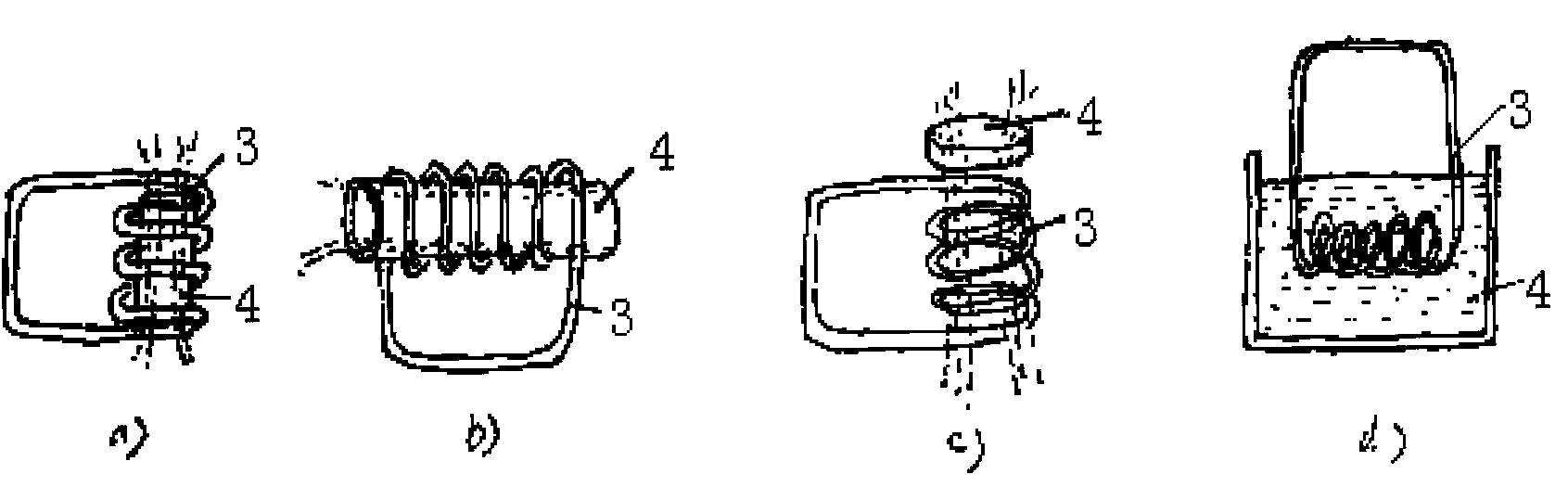

The invention discloses a device for processing food by utilizing high-voltage pulse sensing current. The device comprises a direct-current high-voltage pulse current generator, wherein the direct-current high-voltage pulse current generator is connected with a sensing coil, the direct-current high-voltage pulse current generated by the direct-current high-voltage pulse current generator acts on the sensing coil, so that the magnetic induction flux is varied in a pulse form in the sensing coil, the pulse-form variation of the magnetic induction flux generated by the sensing coil acts on a magnetic conductive coil with high magnetic conductivity, and the variation of the magnetic induction flux is formed inside or near the magnetic conductive coil. The device and the method have the beneficial effects that microorganism cell membrane on the surface and inside of to-be-processed food can be permanently broken down to be eliminated by the pulse current in a noncontact manner, so that the weakness of the existing heating sterilizing method that the nutrients and flavor of the food are damaged can be overcome, the problems of the existing high-voltage pulse electric field method that the electrode needs to be contacted with the food can be avoided, and the application range is enlarged from the liquid food to the solid or particle food.

Description

technical field [0001] The invention belongs to the technical field of food processing, and relates to equipment and a processing method for processing food using high-voltage pulse induction current. Background technique [0002] High-voltage (or high-intensity) pulsed electric field (Pulsed Electric Fields, PEF) is a new type of non-thermal food sterilization technology, which uses a higher electric field strength (10-50kV / cm) and a shorter pulse width (0 -100μs) and higher pulse frequency (0-2000Hz) to process liquid and semi-solid food, and can form a continuous sterilization and aseptic filling production line. The bactericidal principle is to directly interact with the microbial cell membrane through the pulse current, destroy the structure of the cell membrane, and form "electroporation" to inactivate the microorganism. [0003] However, the current PEF technology has the following disadvantages: [0004] (1) The pulsed electric field will affect the electrostatic i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A23L3/32

CPCA23L3/32A23V2002/00A23V2300/46A23V2300/12

Inventor 何宗彦

Owner 江苏合心医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com