An integrated optimization structure of drawer front panel

A technology for optimizing structure and front panel, applied in drawers, furniture parts, home utensils, etc., can solve the problems of inability to adjust and replace, effective accommodation space, insufficient supporting capacity, etc., to improve the overall appearance and low manufacturing cost , the effect of quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

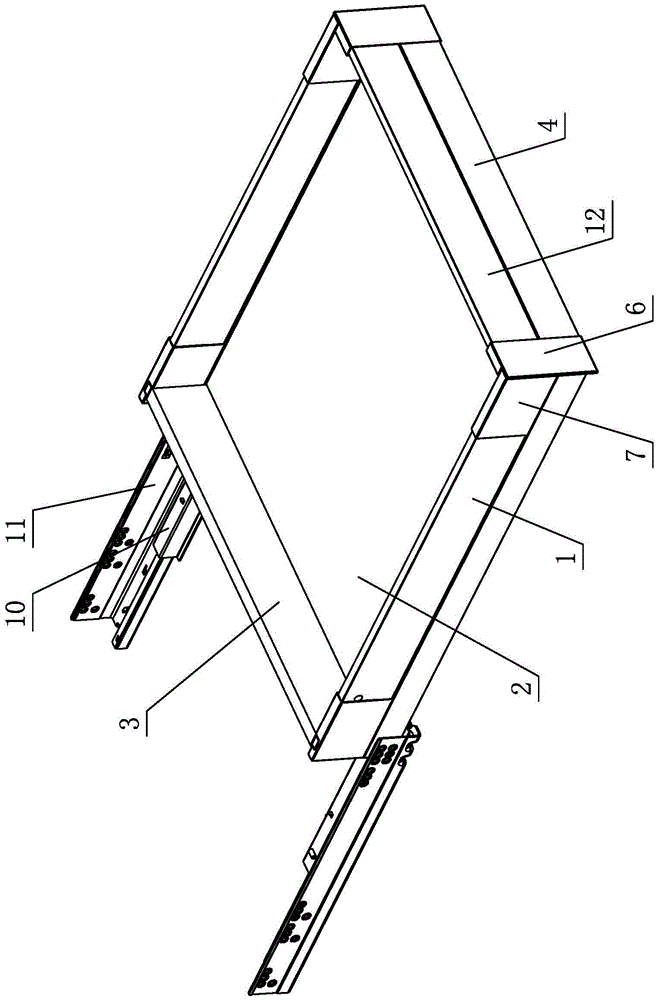

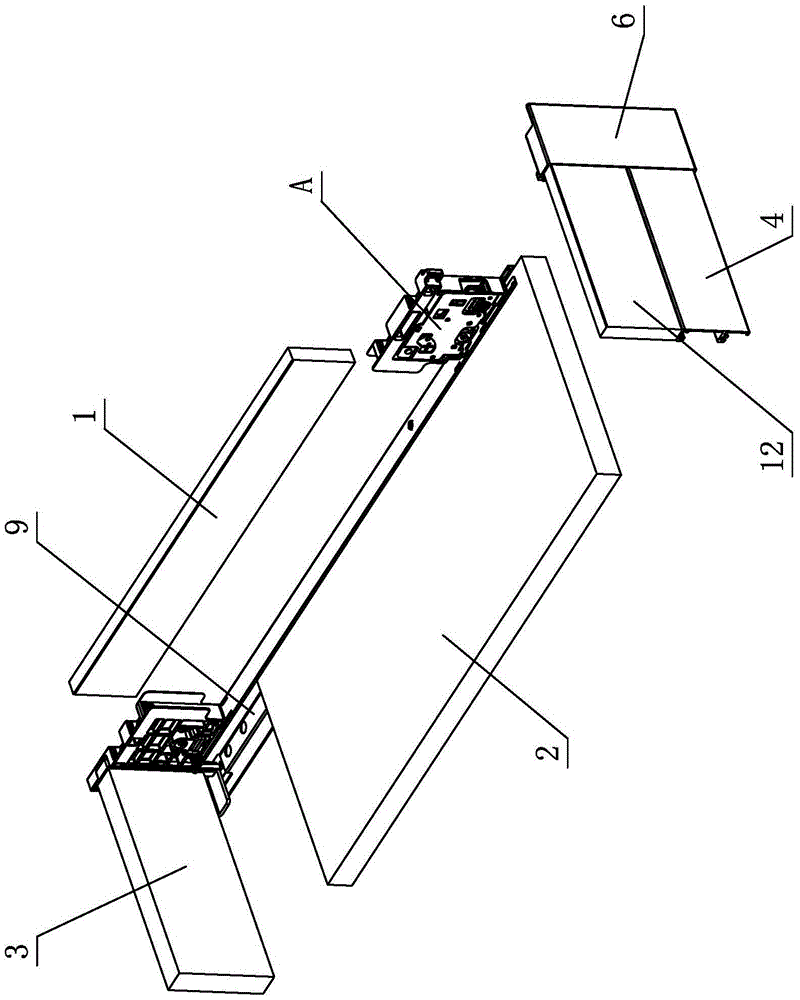

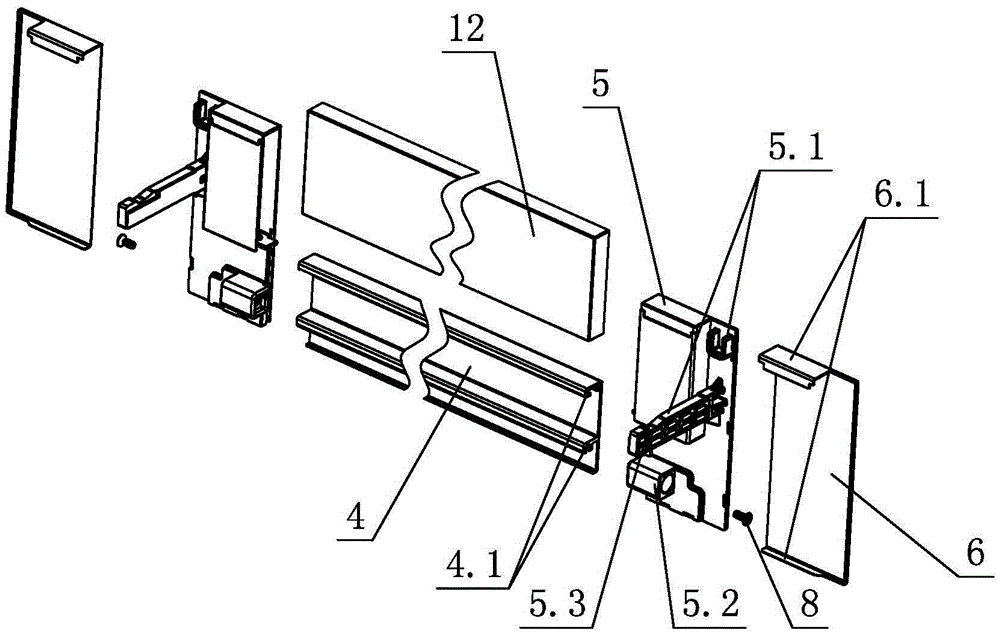

[0023] see Figure 1-Figure 4 , the integrated optimized structure of the front panel of the drawer, including a slide rail assembly, a side panel 1, a bottom panel 2, a back panel 3 and a front panel assembly, wherein the side panel 1 is provided with a locking and disengaging device A connected to the front panel assembly, The front panel assembly includes a metal profile 4 and plastic connectors 5 corresponding to the left and right of the metal profile 4, and the metal profile 4 and the left and right plastic connectors 5 are fixed by fastening units; the front panel assembly is installed by The left and right plastic connectors 5 are mated with the locking and disengaging device A; the outer surface of the plastic connectors 5 is also provided with a metal shell 6 .

[0024] The metal shell 6 is disposed on the outer surface of the plastic connector 5 through the fixing unit. Specifically, the metal shell 6 is provided with a bending portion 6.1, and the bending portion ...

no. 2 example

[0032] see Figure 5 , The integrated optimized structure of the front panel of the drawer is different from the first embodiment in that only one metal profile 4 is arranged between the left and right plastic connectors 5 .

[0033] Other unmentioned parts are the same as the first embodiment.

no. 3 example

[0035] see Figure 6 , the integrated optimized structure of the front panel of the drawer is different from the first embodiment in that: a metal profile 4 and at least a plate 12 of wood, stone, glass, metal, or plastic are arranged between the left and right plastic connectors 5 , the plate 12 is sheathed between the left and right plastic connectors 5 and placed above the metal profile 4 . Two positioning units 5.1 are arranged on the plastic connector 5, and the two positioning units 5.1 are both pins, and the plastic connector 5 acts on the metal cover 7 and the locking and disengaging device A through the pins when the front panel assembly is installed, so as to The up and down and left and right positioning of the front panel assembly relative to the side panel 1 is realized.

[0036] Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com