Driving system for tandem double-dynamic engineering machine

A technology for construction machinery and drive systems, which is applied in the arrangement of multiple different prime movers of power plants, hybrid vehicles, and general power plants, etc., can solve the problems of high fuel consumption, waste pollution, environmental pollution, and many failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

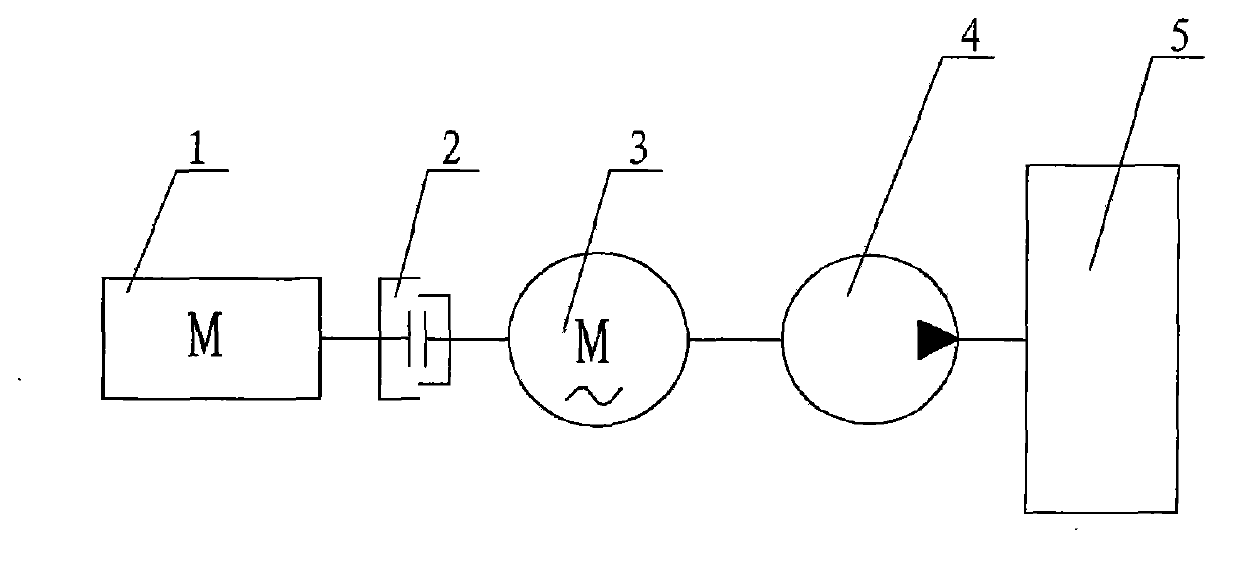

[0007] When the engine operation needs to be selected: the output end of the engine (1) is equipped with a clutch (2), the output end of the clutch (2) is connected with the motor (3), the motor rotor is used as the connecting shaft, and the output end of the motor (3) is installed with an oil pump ( 4), the output end of the oil pump (4) is connected with the working device (5), so that the purpose of driving the tandem dual-power construction machinery can be realized.

[0007] When the engine operation needs to be selected: the output end of the engine (1) is equipped with a clutch (2), the output end of the clutch (2) is connected with the motor (3), the motor rotor is used as the connecting shaft, and the output end of the motor (3) is installed with an oil pump ( 4), the output end of the oil pump (4) is connected with the working device (5), so that the purpose of driving the tandem dual-power construction machinery can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com