Multifunctional ecological inner wall coating material and preparation method thereof

A coating material and ecological technology, which is applied in the field of multifunctional ecological interior wall coating materials and their preparation, can solve the problems of long-term limitation, small coating film thickness, and small total amount of humidity-conditioning materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

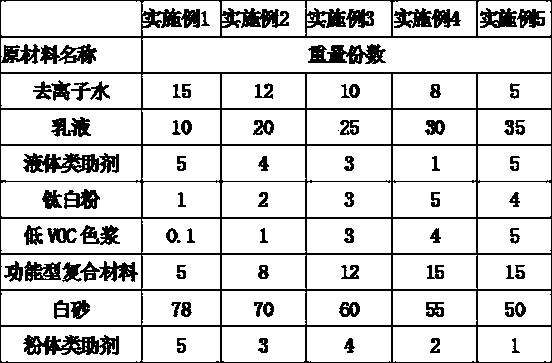

[0041] The preparation method of the multifunctional ecological interior wall coating material in the above-mentioned embodiments 1-5 (Table 1) comprises the following steps:

[0042] 1) First add deionized water and emulsion into the reaction kettle while stirring, then add liquid additives and titanium dioxide in turn, disperse for 15 minutes and then use low-VOC colorant to color the color sample according to the customer's design requirements;

[0043] 2) Add functional composite materials, powder additives, and white sand into the powder mixer and mix for 10 minutes before discharging;

[0044] 3) Slowly add the powder released in step 2) into the reaction kettle under stirring state, mix evenly, inspect, discharge and pack.

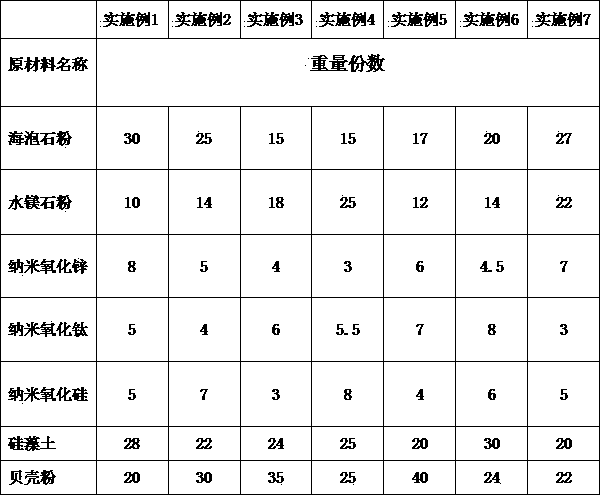

[0045] The functional composite material in the above-mentioned embodiments 1-5, the formula of embodiment 1-7 is as follows: (Table 2)

[0046]

[0047] The preparation method of the functional composite material in the above-mentioned Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com