Fabric clamping suspension clamp

A clamp and cloth clamping technology, which is applied in the direction of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems such as the inability of rubber to meet its requirements, the fracture at the bend of the clamp, and the poor performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

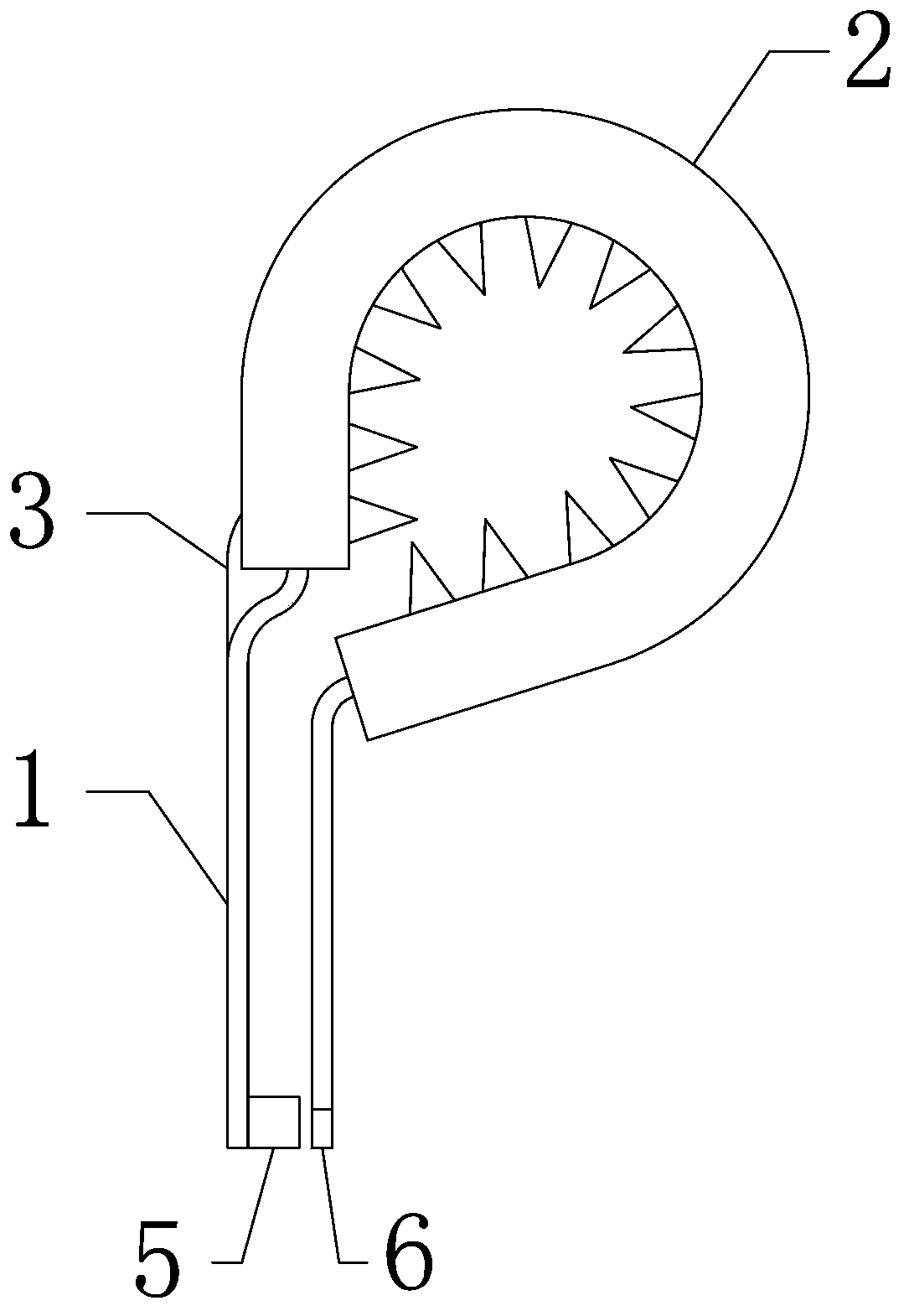

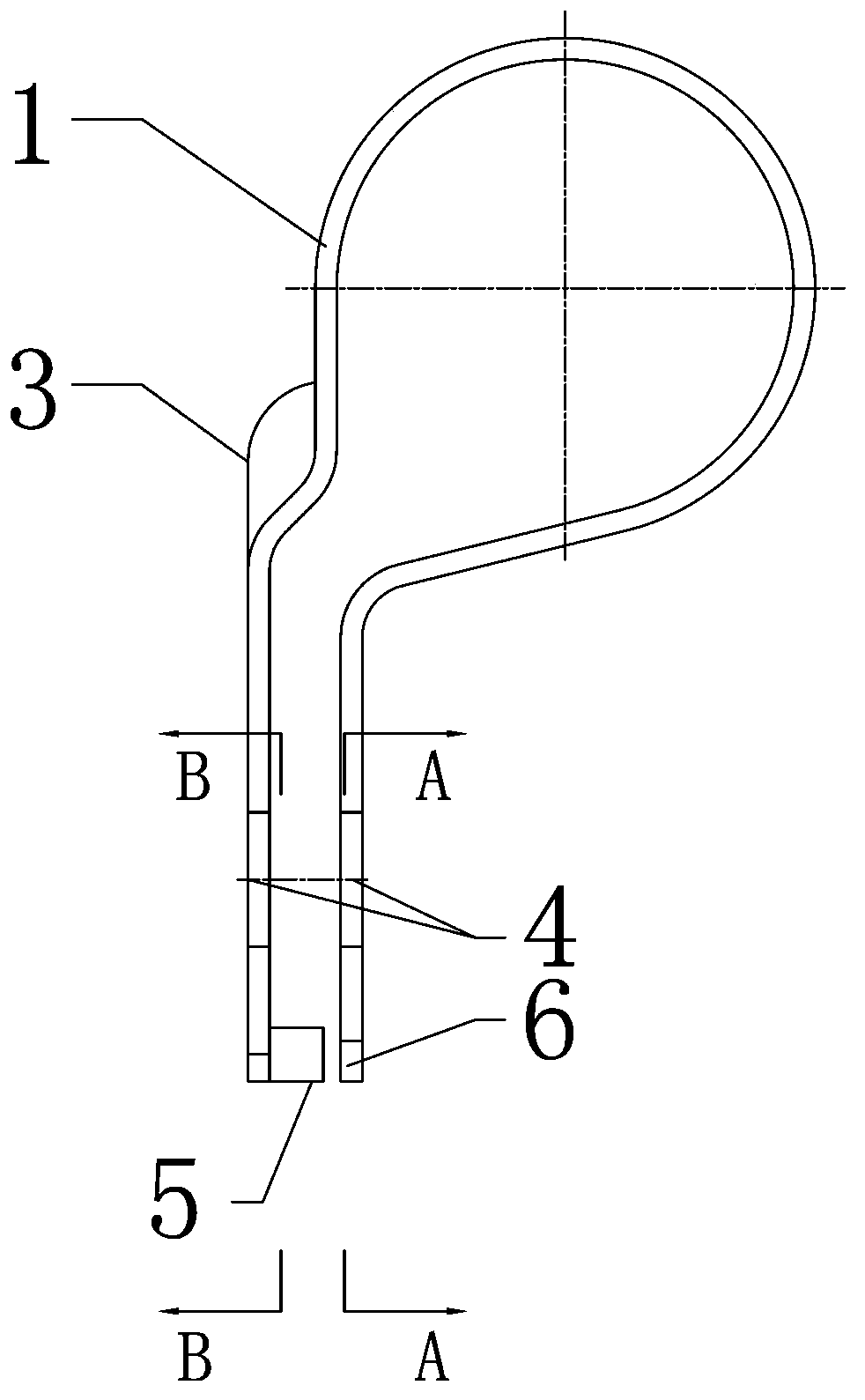

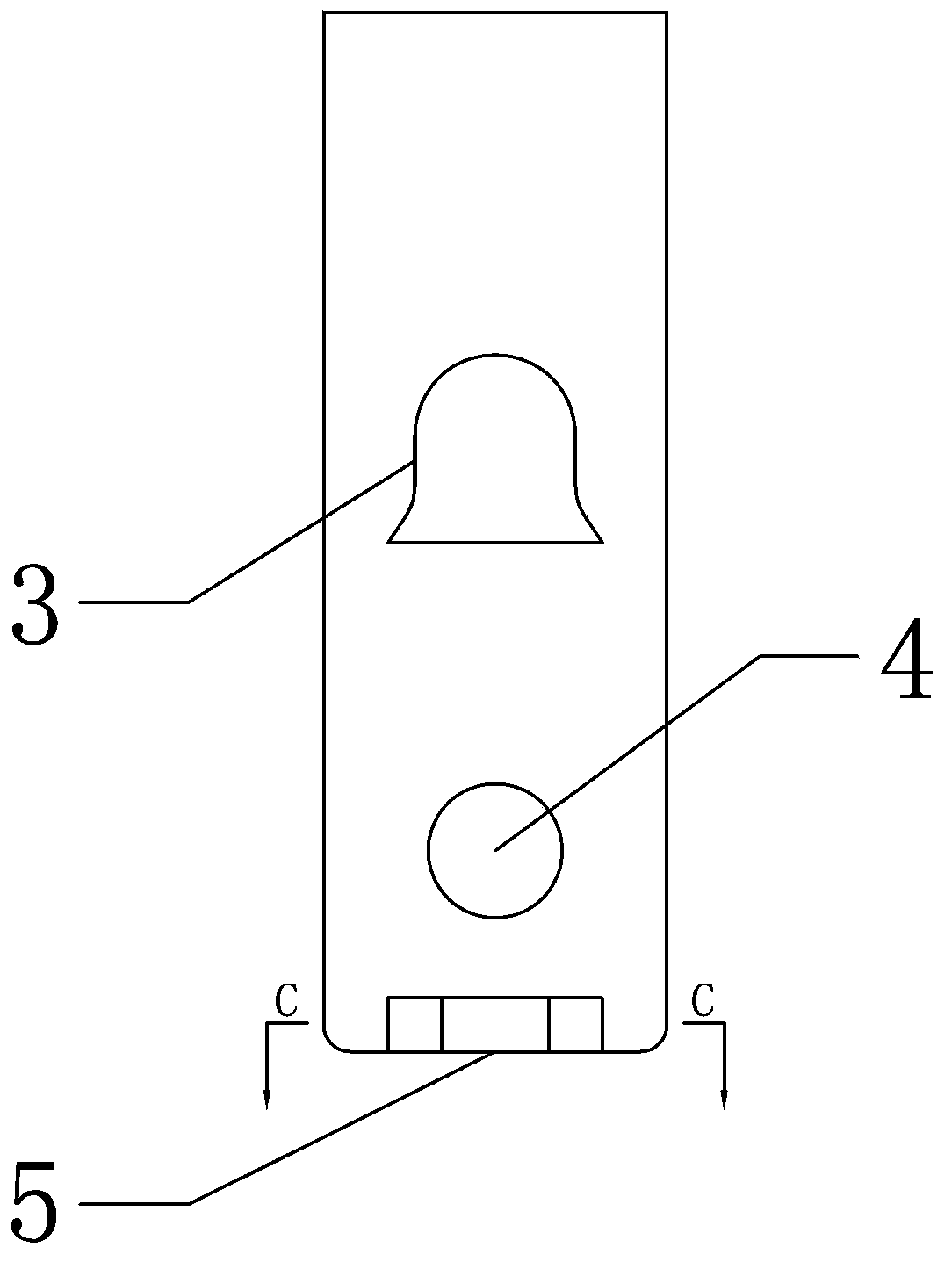

[0020] Such as figure 1 A cloth hanging hoop shown is composed of a band 1 and a rubber pad 2; the upper end of the band 1 is in the shape of a ring, and the lower end is two vertical plates whose inner sides can be fully fitted; the upper end of the band 1 is a ring A reinforcement rib 3 perpendicular to the end face of the band is provided on the outer side of the joint with the lower vertical plate; the two vertical plates at the lower end of the band 1 are processed with corresponding locking through holes 4; the rubber pad 2 is set on the upper end of the band 1 circular part;

[0021] Such as Figure 2 to Figure 5 One of the two vertical plates at the lower end of the band 1 is fixed with a "ji"-shaped clamping groove 5, and the other lower end is processed into a "convex"-shaped clamping block 6, that is, the two vertical plates pass through the "convex"-shaped clamping block 6 The protruding part of the front end extends into the "several"-shaped slot 5 for clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com