Flat plate heat pipe and manufacturing method thereof

A technology for flat heat pipes and manufacturing methods, applied in the field of heat pipes, can solve the problems of poor heat transfer performance of flat heat pipes and inability to meet different requirements at the same time, and achieve the effect of avoiding dry burning and ensuring working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

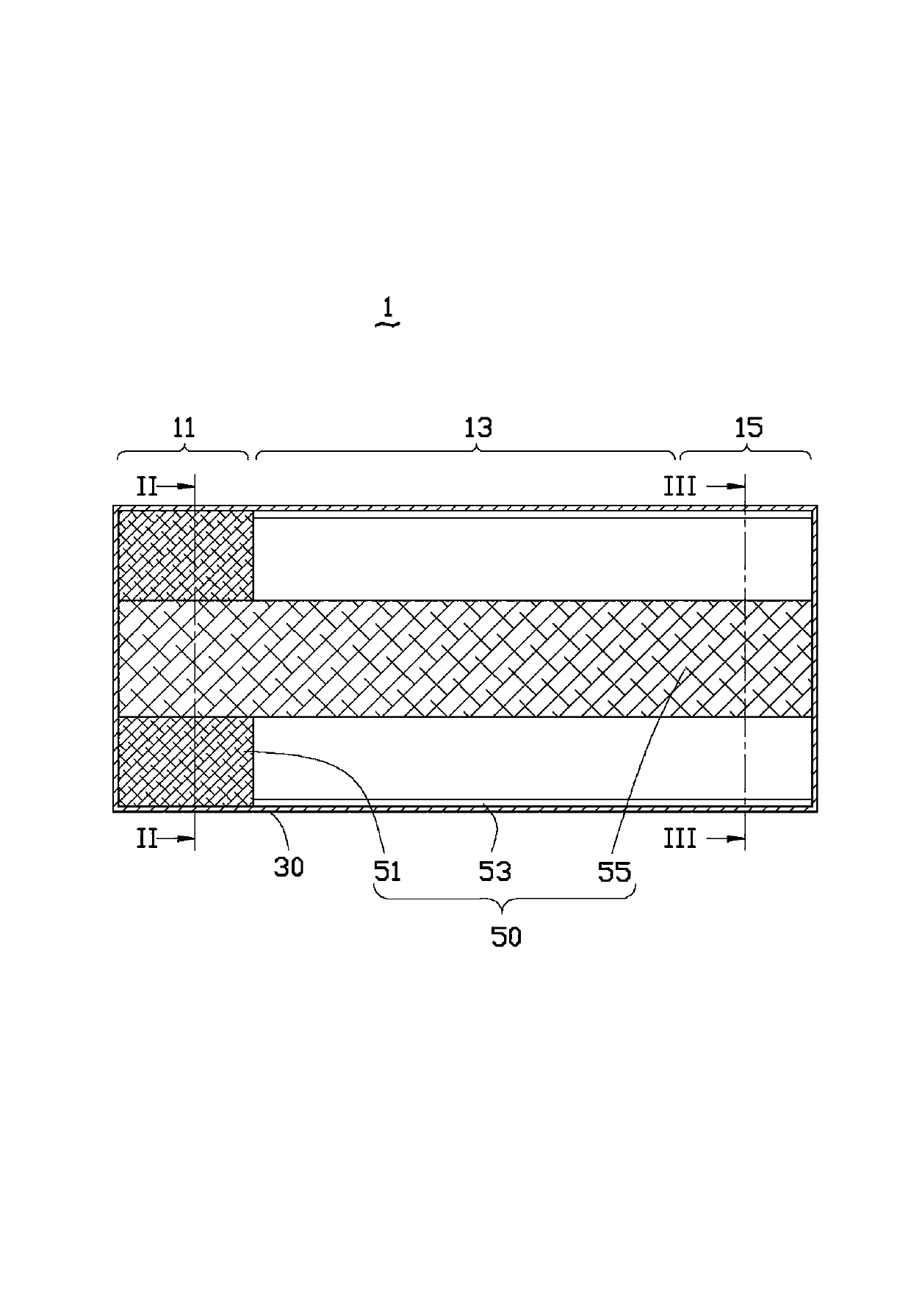

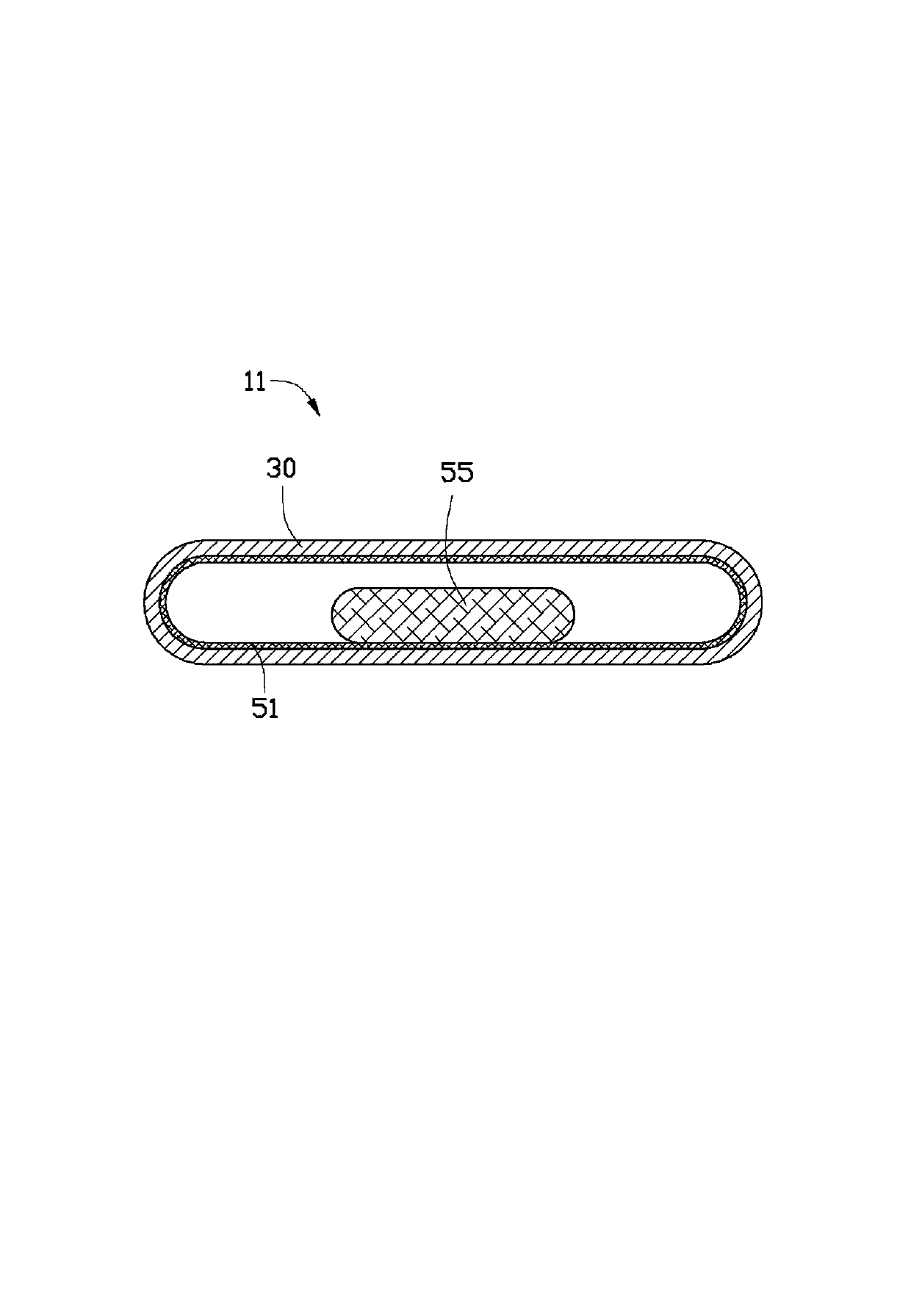

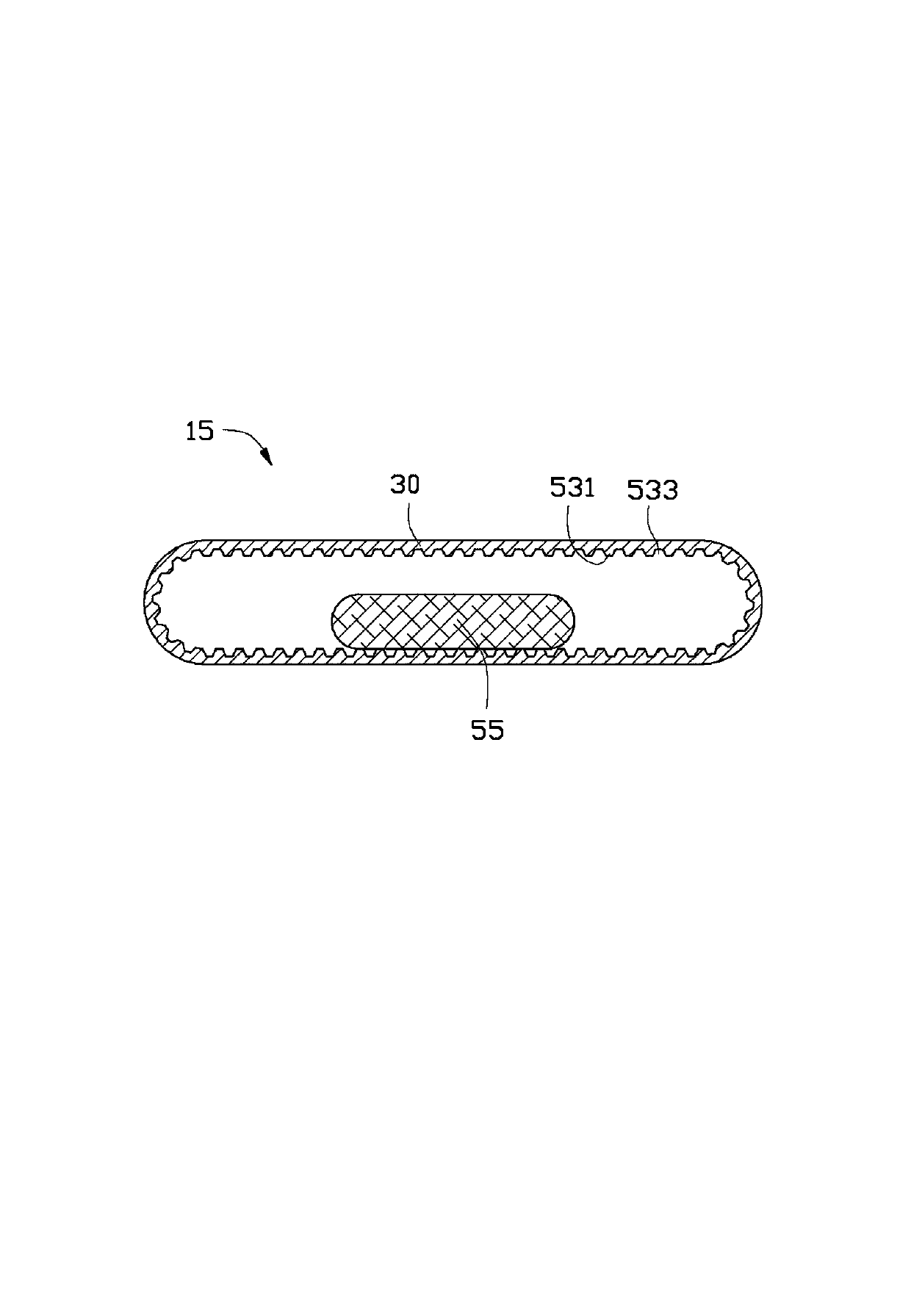

[0022] Such as Figure 1 to Figure 3 Shown is the flat heat pipe 1 of the first embodiment of the present invention. The flat heat pipe 1 is a longitudinal pipe body, along its length direction, there are sequentially connected an evaporation section 11 , a heat transfer section 13 and a condensation section 15 . The flat heat pipe 1 includes a shell 30 , a capillary structure 50 attached to the inner surface of the shell 30 , and a working fluid (not shown) contained in the capillary structure 50 . The housing 30 is a hollow and elongated flat tube with the same depth everywhere and sealed against both ends. The cross section of the housing 30 is racetrack-shaped.

[0023] The capillary structure 50 includes a first capillary structure 51 located at the evaporation section 11, a second capillary structure 53 connected to the first capillary structure 51 and extending from the heat transfer section 13 to the condensation section 15, and a second capillary structure 53 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com