Stereo led illuminant and its processing method

A luminous body and three-dimensional technology, which is applied in the direction of semiconductor devices, electric solid devices, electrical components, etc., can solve the problems affecting the quality of the lamp body, the lead wires are not easy to fix, and the welding connection is difficult, so as to reduce the difficulty of production operation and facilitate production operation and fixation , Precise and stable positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

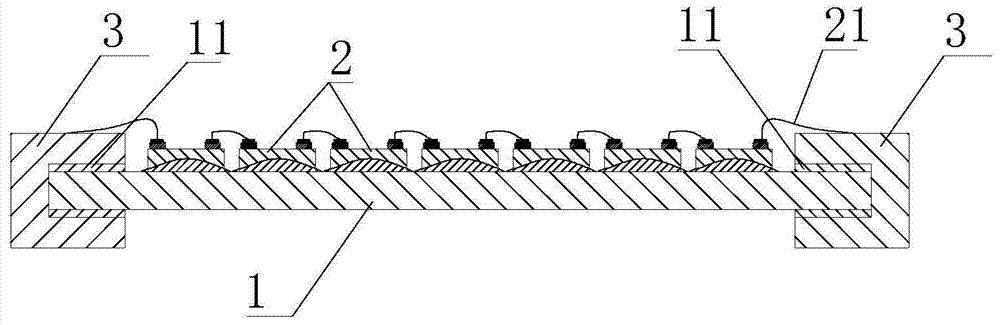

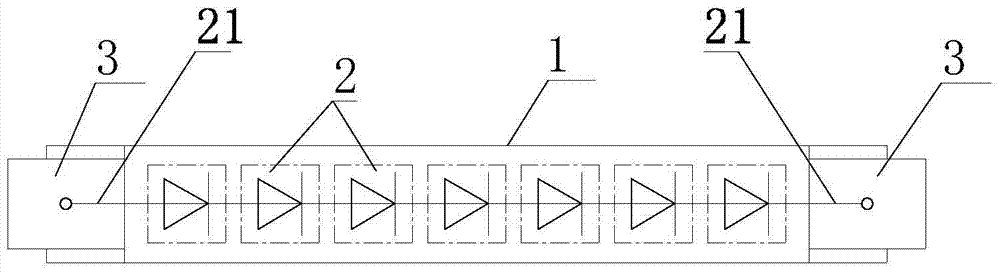

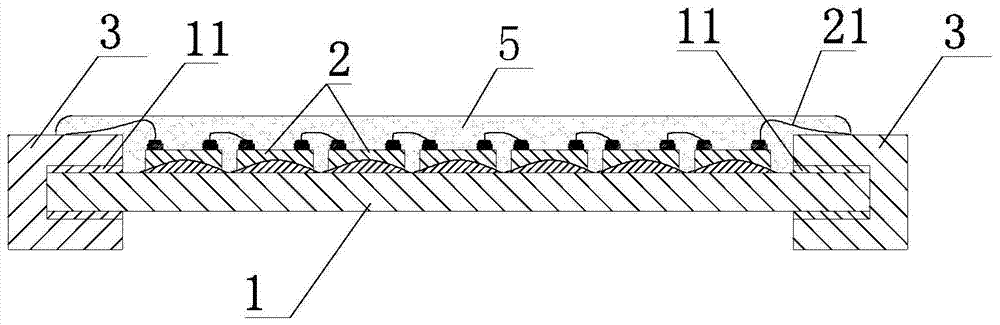

[0044] like Figure 1 to Figure 7 As shown: a three-dimensional LED illuminant, including a strip-shaped transparent substrate 1 and several LED chips 2 connected in series. The two ends of 1 are respectively provided with metal connectors 3, and the metal connectors 3 are provided with U-shaped bayonets 31, which are buckled on both ends of the transparent substrate 1, and the metal connectors 3 and the transparent substrate 1 are fixed with glue. , the lead wire 21 is electrically connected to the metal connector 3 .

[0045] like Figure 7 As shown, metal terminals 11 are printed on both ends of the transparent substrate 1 , and the U-shaped metal connector 3 is buckled on the metal terminals 11 .

[0046] The lead wire 21 is welded to the metal connector 3 .

[0047] The lead wire 21 is welded to its opposite metal terminal 11 and sandwiched between the metal connector 3 and the metal terminal 11 .

[0048] The glue is a conductive glue.

[0049] The substrate of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com