A pressure switch and electric pressure cooker for precise pressure control

A pressure switch, precise technology, applied in pressure cookers, cooking utensils, household appliances, etc., can solve the problems of inaccurate pressure control of pressure switches, user safety threats, easy to exceed safety pressure, etc., to improve use safety and improve pressure control. Accuracy and good product applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

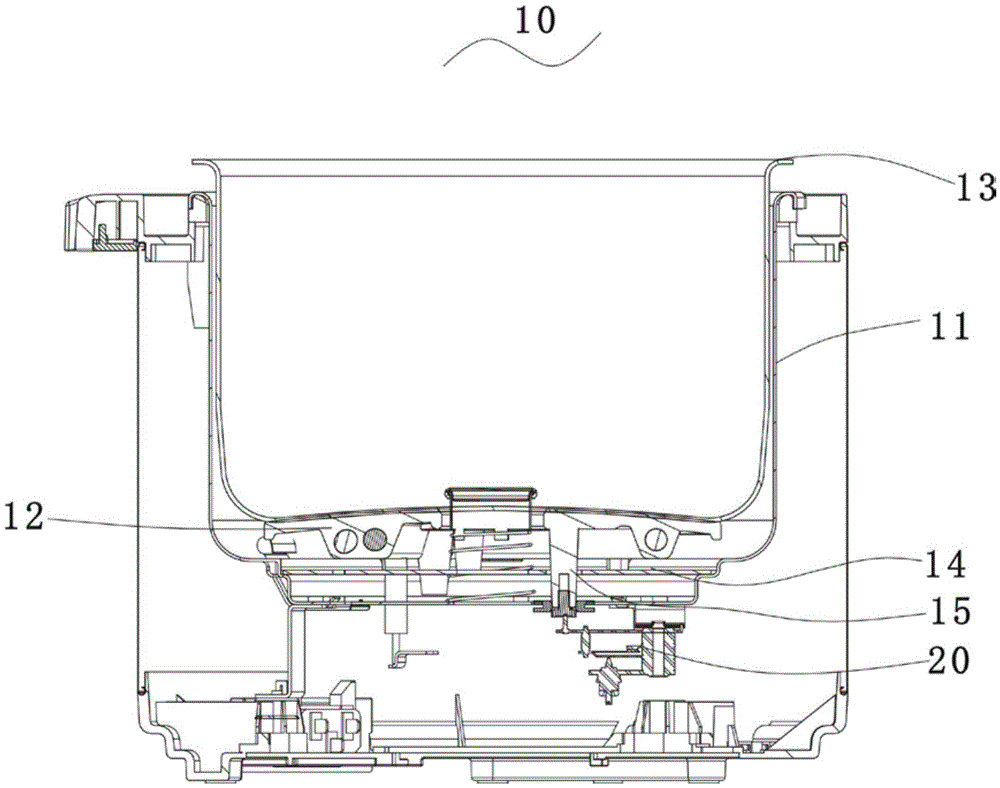

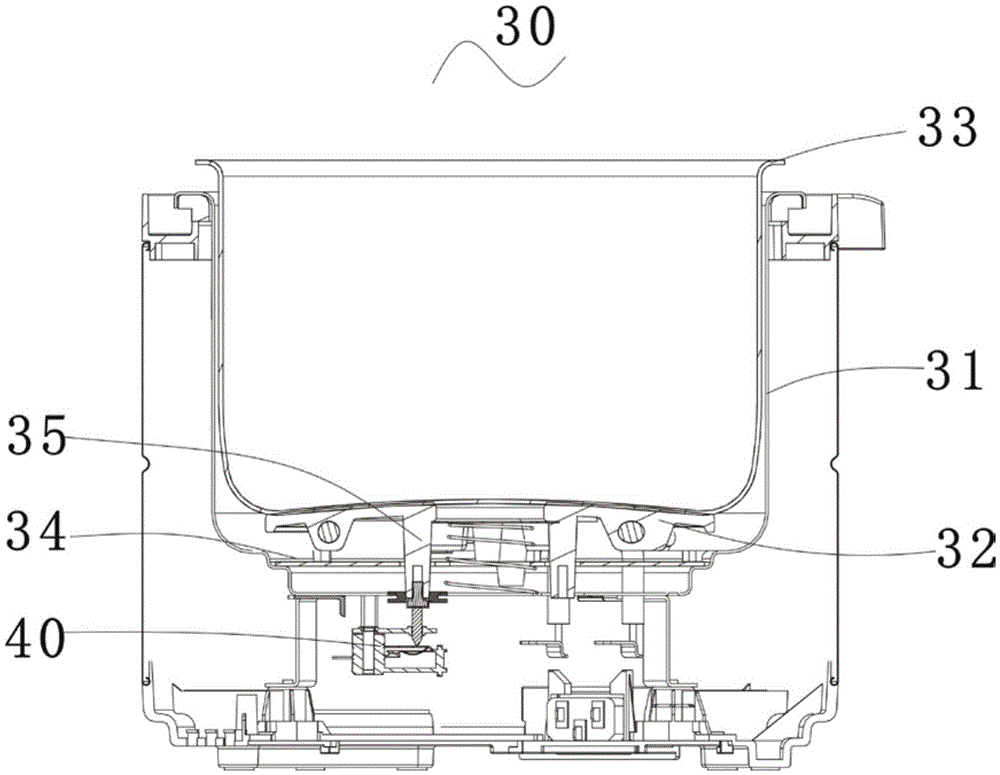

[0059] The invention provides an electric pressure cooker, please refer to image 3 The electric pressure cooker includes a pot cover and a pot body 30, and the pot body 30 includes an outer pot 31, and a heating device is installed on the bottom of the outer pot 31. In this embodiment, the heating device is a heating plate 32. In other embodiments of the present invention Among them, the heating device can also be other conventional heating devices, the heating plate 32 is provided with an inner container 33, the inner container 33 and the pot cover form a cooking cavity, and the heating plate 32 is provided under the legs. Elastic support structure 34, the legs of the heating plate 32 are supported on the elastic support structure 34. In this embodiment, the elastic support structure 34 is located between the bottom of the outer pot 31 and the legs of the heating plate 32, such as the elastic support The structure 34 can be a known structure such as a disc spring, an elastic...

no. 2 example

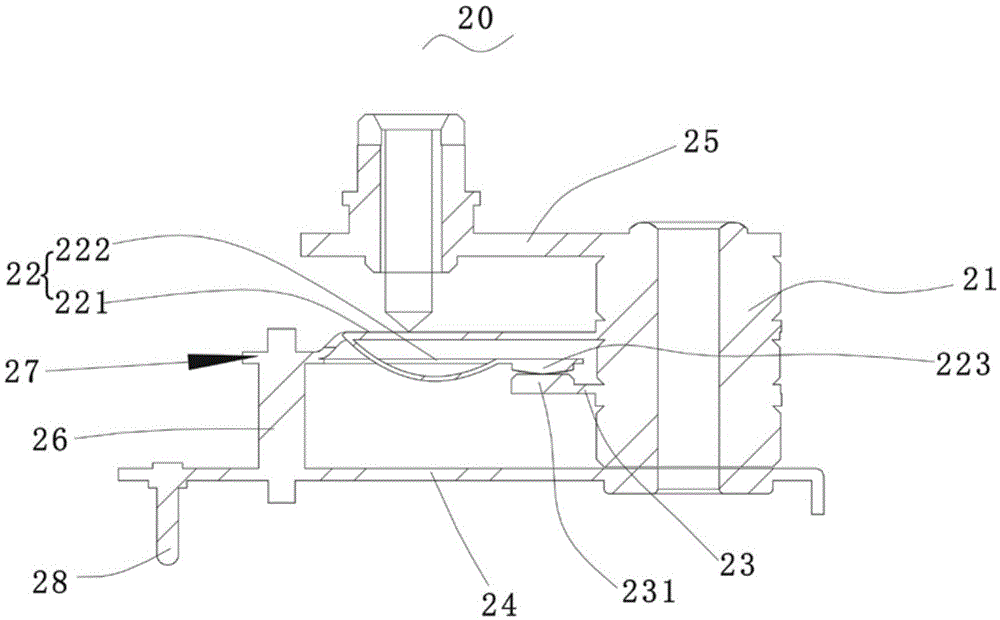

[0075] Figure 9 is a sectional view of the pressure switch according to the second embodiment of the present invention, Figure 9 structure with Figure 4 The structures are similar, so the same component symbols represent the same components. The main difference between this embodiment and the first embodiment is that the push rod is movable.

[0076] See Figure 9 , in this embodiment, the upper positioning block 45 is made of rigid material, that is, the upper positioning block 45 is a rigid positioning block, and the push rod 56 is installed on the upper positioning block 45 and can move toward the positioning piece 421. And the push rod 56 pushes the positioning piece 421 to disconnect the moving elastic piece 422 from the lower electrode piece 43, specifically, the push rod 56 pushes the positioning piece 4212 to make the moving elastic piece 422 disconnect from the lower electrode piece 43. disconnected, the push rod 56 is located between the connecting rod 41 and t...

no. 3 example

[0083] Figure 10 is a sectional view of the pressure switch according to the third embodiment of the present invention, Figure 10 structure with Figure 9 The structures are similar, so the same component symbols represent the same components. The main difference between this embodiment and the second embodiment is that the pressure switch cannot be reset after it is disconnected.

[0084] See Figure 10 , the upper positioning block 45 is made of rigid material, and a push rod 66 is installed on the upper positioning block 45, and the push rod 66 can move on the upper positioning block 45, and the push rod 66 pushes the positioning shrapnel 4212 to make The moving elastic piece 422 is disconnected from the lower electrode piece 43 , and the push rod 66 is located between the connecting rod 41 and the fixed connection point 47 , specifically, the pushing rod 66 is located above the positioning elastic piece 4212 .

[0085] In this embodiment, the upper positioning block 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com