Gas precise dispensing device

A sub-packaging and accurate technology, applied in the installation device of container structure, gas/liquid distribution and storage, gas processing application, etc. The problem of high pressure at the bottle mouth of the container can reduce the pressure error, reduce the amount of impurities mixed in, and achieve the effect of accurate sub-packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

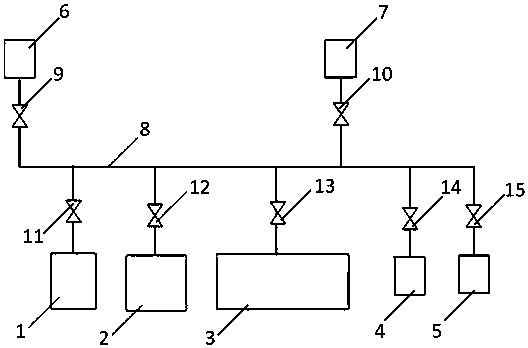

[0019] The gas precision dispensing device of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments:

[0020] Such as figure 1 As shown, a precise gas dispensing device includes vacuum pumping equipment 6, No. I container 1, No. II container 2, No. III container 3, gas container 4 and packaging A pressure gauge 7 is installed on the container 5 and the main pipe 8; a D stop valve 9 is installed between the vacuum pumping equipment 6 and the main pipe 8; a No. I stop valve 11 is installed between the No. I container 1 and the main pipe 8; II No. II stop valve 12 is set between No. container 2 and main line 8; No. III stop valve 13 is set between No. III container 3 and main line 8; F stop valve 14 is set between gas container 4 and main line 8 ; The S cut-off valve 15 is set between the sub-packaging container 5 and the main pipeline 8;

[0021] The volume of the No. I container 1 is 5L; the volume of the No. II ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com